Replacement nozzles for die casting machines are critical components that ensure efficient molten metal transfer from the shot sleeve to the mold cavity.

Their design, material, and compatibility directly impact production quality and machine longevity.

Below is a detailed guide to selecting and maintaining these nozzles, based on industry standards and supplier offerings:

Overall analysis of die-casting nozzle structure

- Types of Replacement Nozzles

- Key Selection Criteria

- Leading Suppliers

- Maintenance Best Practices

- Cost and Availability

Types of Replacement Nozzles

- By Material:

- H13 Tool Steel:

- Properties: High thermal fatigue resistance, moderate wear resistance, cost-effective.

- Applications: General-purpose use for aluminum, zinc, and magnesium alloys .

- Tungsten Carbide:

- Properties: Extreme hardness and wear resistance, ideal for high-volume production of abrasive alloys (e.g., aluminum with silica additives) .

- Ceramic-Coated Nozzles:

- Properties: Low friction, anti-sticking surface, reduces soldering (metal adhesion) in aluminum die casting .

- H13 Tool Steel:

- By Design:

- Flat-End Nozzles: Standard for most applications, ensuring consistent flow.

- Tapered Nozzles: Reduce turbulence during injection, ideal for thin-walled parts like electronics housings .

- Stepped Nozzles: Improve sealing in high-pressure systems (e.g., engine blocks) .

Key Selection Criteria

- Compatibility: Match the nozzle to your machine type (hot chamber for zinc/magnesium; cold chamber for aluminum/copper) .

- Production Volume: Tungsten carbide nozzles are preferred for high-volume runs due to durability .

- Alloy Type: Aluminum requires wear-resistant materials (ceramic-coated or tungsten carbide), while zinc/magnesium can use H13 steel .

- Precision Requirements: Advanced systems emphasize closed-loop control for consistent nozzle performance .

Leading Suppliers

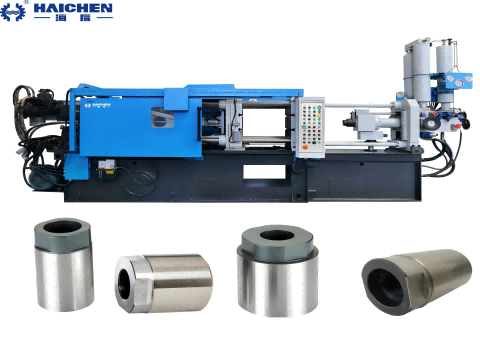

- Haichen :Haichen is located in Ningbo, Zhejiang, China. Haichen specialized in the production and sale of hot chamber die-casting machines, cold chamber die-casting machines, servo die casting machines, magnesium alloy die-casting machines, and relative auxiliary equipment.

- L.K. International Die-Casting Limited: Offers cold/hot chamber machine nozzles with ISO 9001 certification.

- Ningbo Dongfang: Specializes in hot/cold chamber die casting machines and replacement parts.

- Guangdong Shimi Intelligent Equipment Co., Ltd: Provides customized nozzles for high-performance applications.

- YIZUMI: Known for precision nozzles integrated with AI-driven control systems (e.g., ORCA Control System) 3.

Maintenance Best Practices

- Lubrication: Use high-temperature lubricants to reduce friction and prevent soldering .

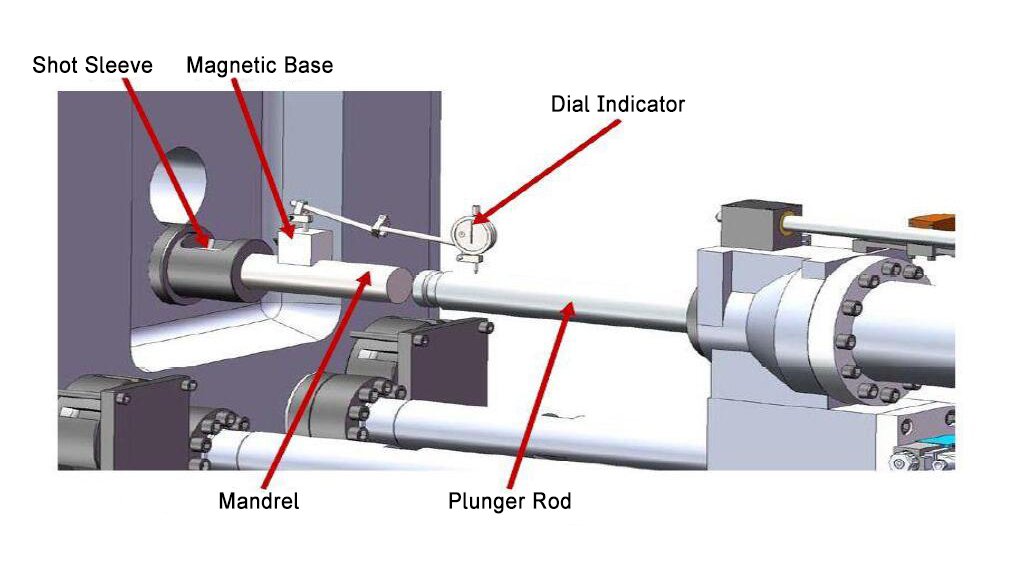

- Alignment Checks: Ensure proper fit with the shot sleeve to avoid leakage or uneven wear .

- Regular Inspection: Replace nozzles showing >0.1 mm wear or surface cracks to maintain part quality .

Cost and Availability

- Price Range: Varies by material and design:

- H13 steel nozzles: 150–150–500 per unit.

- Tungsten carbide/ceramic-coated nozzles: 800–800–2,000+ per unit .

- MOQ: Many suppliers offer single-unit purchases, but bulk orders (10+ units) may reduce costs by 10–20% .

Choosing the right replacement nozzle involves balancing material durability, machine compatibility, and production demands. For high-volume aluminum casting, tungsten carbide nozzles are optimal, while H13 steel suits general-purpose applications. Reputable suppliers HAICHEN provide certified solutions with advanced features like real-time monitoring and AI-driven control. Regular maintenance and alignment checks are essential to maximize nozzle lifespan and ensure defect-free production.

The nozzle is an important component of the die-casting machine.

Special new injection nozzle

Hot-chamber die-casting nozzle heaters&Hot-chamber gate nozzles

Haichen supplies diverse products for the foundry industry, such as hot-chamber die-casting. We can retrofit enclosed nozzle heaters to achieve uniform heating of the melt channel, offering exceptionally long service life. When employing ZD 50/80 and ZD 125 gate nozzles for lead and zinc die casting, the melting point can be positioned directly ahead of the parting line, significantly reducing gate length. Production cycles can be shortened by up to 40%, whilst simultaneously enhancing the quality of the castings.

Haichen Die Casting Machine Nozzles

As a leading manufacturer of die casting machines, Haichen specializes in nozzle design and application for hot-chamber die casting machines, particularly optimized for low-melting-point alloys like zinc and lead. Below is a comprehensive analysis of Haichen’s nozzle technology:

- Nozzle Types and Materials

- Design Features and Functionality

- Applications and Case Studies

- Quality Assurance and Maintenance

- Innovation and Industry Standards

Nozzle Types and Materials

- Hot-Chamber Nozzles:

Haichen’s hot-chamber machines (e.g., HCH series) feature integrated nozzles that serve as the critical pathway for molten metal transfer from the gooseneck to the mold. These nozzles are immersed in high-temperature molten metal (e.g., zinc alloy, ~420°C) and are engineered from high-strength heat-resistant steel with advanced heat treatment to ensure durability under extreme pressure and temperature. For instance, nozzles and goosenecks in 50-ton hot-chamber machines use specialized steel alloys to guarantee long-term stability.

Design Features and Functionality

- Turbulence Reduction and Flow Optimization:

Nozzles are designed to minimize turbulence via precision-engineered diameters, lengths, and tapers, ensuring smooth metal flow into the mold cavity. This reduces porosity and enhances surface finish. - Modular Maintenance:

A modular design enables rapid nozzle replacement and maintenance, minimizing downtime. Haichen also provides standardized spare parts for easy local procurement. - Cooling and Temperature Control:

Select nozzles integrate water- or air-cooling systems to regulate temperature, preventing overheating or premature solidification, thereby improving casting density and consistency.

Applications and Case Studies

- Typical Use Cases:

Haichen’s nozzles are widely used in producing zinc alloy components such as door handles, lock cores, and plumbing fittings. For example, a 90-ton zinc alloy machine supports 4-cavity molds for high-efficiency production of complex door handles. - Automotive and Consumer Electronics:

Thin-walled LED housing production leverages nozzle precision to ensure rapid filling with aluminum or zinc alloys, achieving high strength and thermal dissipation.

Quality Assurance and Maintenance

- Warranty and Service:

Haichen offers a two-month warranty on hot-chamber nozzles, with lifespan extended through proper operation and specified materials. Routine maintenance includes wear inspection and lubrication; the centralized lubrication system auto-replenishes every 500–700 cycles. - Compatibility and Spares:

Critical components (e.g., nozzles) comply with international standards (e.g., Vickers hydraulic systems), allowing users to source replacements locally, reducing downtime and costs.

Innovation and Industry Standards

- Smart Control Systems:

Haichen machines feature multi-language control interfaces (e.g., English, Spanish, Russian), real-time injection curve monitoring, and servo-driven energy-saving systems for precise nozzle control and efficiency. - Certifications:

Products meet ISO 9001, CE, and GB/T 21269-2023 standards, ensuring industry-leading performance and safety.

More you need to know

Haichen’s nozzle technology excels in high-strength materials, modular design, and smart control, making it ideal for hot-chamber zinc/lead alloy casting. Optimized flow paths and cooling systems enhance quality and productivity, while global spare parts networks and rigorous quality management ensure reliability. For customized solutions or model-specific details, contact Haichen directly for technical support.

This translation retains technical accuracy while aligning with industry terminology and readability standards.

Contact Haichen anytime for more die casting technical support.