Servo motor Control die-casting machine is a special die-casting machine driven by a high-precision control servomotor.

It can improve the control precision of the power system, simplify the structure, and extend the service life of key components, reduce the consumption of raw materials, and make the overall structure more concise.

In addition, the servo motor through the closed-loop control system to achieve accurate position, speed and force control, so as to improve production efficiency and product quality.

Servo motor Control die-casting machines also have the advantages of energy saving, low noise and extended equipment life.

Features of Servo Motor Control Die Casting Machine

Servo Control die-casting machine with energy saving, high efficiency and environmental protection and other special advantages.

Mainly has the following eight characteristics:

- Energy saving and high efficiency

- Servo drive response quickly

- Die casting machine moulding high precision

- Low noise operation

- Convenient maintenance

- Strong adaptability

- Servo drive environmental protection and energy saving

- Enhance production efficiency

Energy saving and high efficiency

Die casting Servo drive system through the closed-loop control to achieve the pressure and flow rate of accurate adjustment, to avoid the traditional quantitative pump system of high-pressure overflow phenomenon, energy saving rate of up to 40% -80%.

Servo Control rapid response

Servo system response speed, pressure and flow rate change time as short as 30ms, significantly improve production efficiency.

High moulding precision of die-casting machine

Servo system pressure is stable, pressure fluctuation is less than ± 0.05MPa, to ensure product moulding precision and consistency.

Low noise operation

Servo die-casting machine running low noise, improve the working environment.

Convenient maintenance

Servo system is compact, simple maintenance, internal maintenance can be completed within 4 hours.

Strong adaptability

Servo die-casting machine is suitable for a variety of materials and complex processes, especially in high-precision, high-quality production line performance.

Servo drive environmental protection and energy saving

Die-casting machine with servo motor standby almost no energy consumption, reducing carbon emissions.

Enhance production efficiency

Servo die-casting machine through the optimisation of sliding motion configuration and control parameters, significantly improve the production beat and qualified rate.

Different types of Servo Motor Control Die Casting Machine

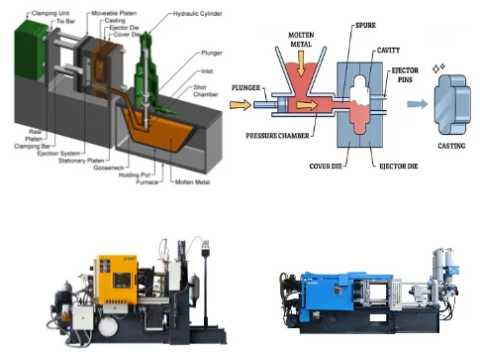

Servo Control die-casting machines have different drive systems, and specific applications therefore there are various types of design.

Mainly includes five kinds:

- Cold chamber servo die-casting machine

- Mechanical servo die casting machine

- Electro-hydraulic servo die-casting machine

- Servo energy-saving transformation die-casting machine

- Servo Control screw press

Cold chamber servo die-casting machine

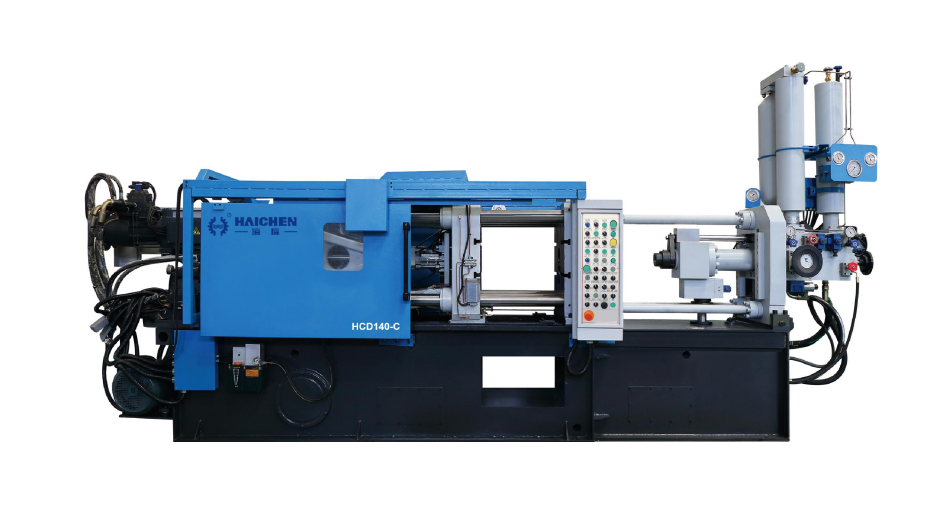

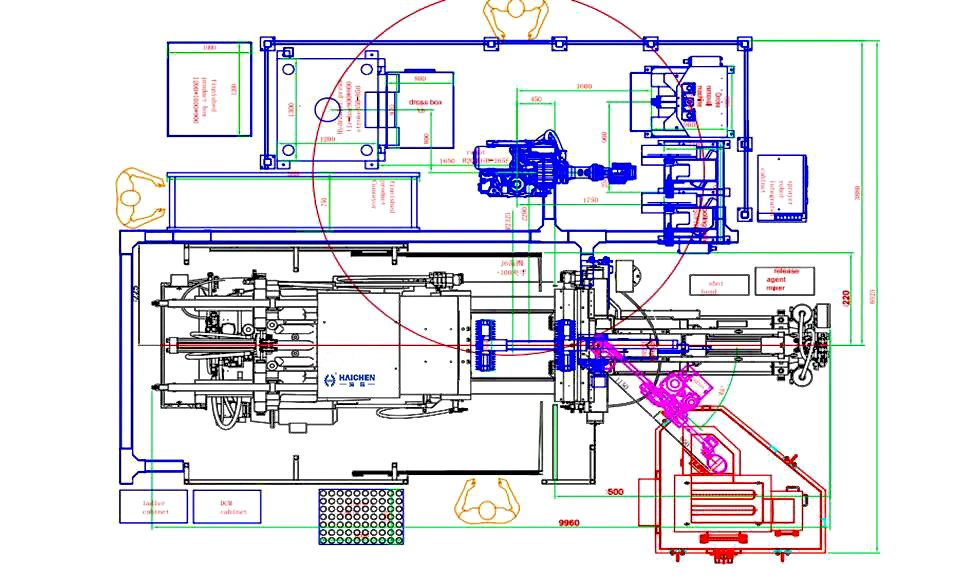

HCD 1680-C cold chamber servo die casting machine, suitable for aluminium alloy, magnesium alloy and other materials, high precision, high quality casting.

Mechanical servo die casting machine

Haichen HCD series servo die casting machine, through the servo motor drive, provide flexible stroke and sliding motion configuration, suitable for a variety of metal forming needs.

Electro-hydraulic servo die-casting machine

Using servo motor and hydraulic system combination, with high precision, energy saving, rapid response and other characteristics, suitable for large-scale production.

Servo energy-saving transformation die-casting machine

Through the servo motor technology on the traditional die casting machine energy saving transformation, improve efficiency and stability.

Servo Control screw press

Such as ZES type servo Control screw press, suitable for precision forging processing.

These types of servo Control die casting machine in different application scenarios show their respective advantages.

Such as high precision, energy saving, fast response and adaptability.

Development history of Servo Motor Control Die Casting Machine

Servo Control die-casting machine development history has experienced from the traditional mechanical die-casting machine to hydraulic die-casting machine, and then to the modern servo electric die-casting machine evolution.

Early die casting machine mainly rely on mechanical and hydraulic drive, low efficiency and difficult to achieve precision control.

With the progress of technology, servo drive technology gradually applied in die casting machine, brought significant energy saving, precision enhancement and improve production efficiency.

Servo die-casting machine through the servo motor and ball screw to achieve precise control, reduce energy waste, and optimise the production process.

In recent years, servo die-casting machines have been widely used in automotive, aerospace and other industries, and have become important equipment for modern metal processing.

Haichen’s cost-effective Servo Motor Control Die Casting Machine

Haichen’s cost-effective servo Control die casting machines are technologically mature and have excellent market performance.

We have a mature understanding of servo control die casting machine research and development after years of design exploration and market operation.

Haichen servo control die casting machine five aspects of advantages:

- High performance and energy saving

- Multi-function and flexibility

- Servo control technology speed advantage

- Reliability and stability

- Market recognition

High performance and energy saving

Haichen’s servo Control die casting machine adopts advanced servo system, which is able to achieve high-precision and high-efficiency production, and at the same time, it has remarkable energy-saving effect, which is 40%-70% more energy-saving than traditional die casting machine.

Multi-function and flexibility

The model is suitable for die casting of many kinds of non-ferrous metals, such as zinc, aluminium and lead, widely used in automotive, home appliances, 3C electronic products and other industries.

Servo control technology speed advantage

Haichen’s servo system has fast response speed and precise pressure and flow control, which ensures high quality and production efficiency.

Reliability and stability

Servo control technology reduces the maintenance cost of the equipment and improves the service life and stability of the equipment.

Market recognition

Haichen brand enjoys a high reputation in the market with years of experience and technology accumulation, and its products are known for high cost performance.

Haichen’s servo control die casting machine is a cost-effective choice as it excels in performance, energy saving, versatility and market recognition.

Choose Haichen’s servo Control die casting machines and let us configure the perfect production solution for your metal die casting products.