The die casting operation steps involve preparing the mold, heating metal, injecting it into the mold, cooling, ejecting the part, post-processing, etc.

Die casting stands out as a go-to method for creating detailed components across many industries, thanks to its compatibility with versatile materials like aluminum, zinc, and copper alloys.

Understanding the importance of each step in the die casting operation is crucial for ensuring consistent and reliable production.

In this article, we will explore the key steps involved in the die casting operation, highlighting the importance of precision and control in achieving high-quality results.

Additionally, we will discuss how these steps contribute to the overall efficiency and reliability of the die casting process.

Die Casting Process Steps: A Step-by-Step Guide

The die casting process requires strict implementation to produce high-quality metal parts. Let’s take a step-by-step look at how this high-pressure casting process works:

- Mold preparation: The operator will first clean the mold and apply lubricant to prevent the casting from sticking to the mold.

- Metal injection: We quickly press the molten metal into the mold under high pressure.

- Cooling and shaping: The metal stays in the mold for a sufficient time and naturally solidifies into shape.

- Ejection of the part: The cooled casting is pushed out of the mold with an ejector mechanism.

- Post-processing: Trim off the burrs and carefully check the quality of each casting.

These five links are closely connected and directly affect production efficiency and finished product quality. Familiarity with these steps can help us reduce defects and optimize the entire casting process.

Die casting operation steps

- Preparing the Die Cavity

- Die casting operation steps-Heating the Metal

- Injecting the Molten Metal

- Cooling and Solidification

- Die casting operation steps-Ejection of the Casting

- Post-processing

- Inspection and quality control

- Finishing touches

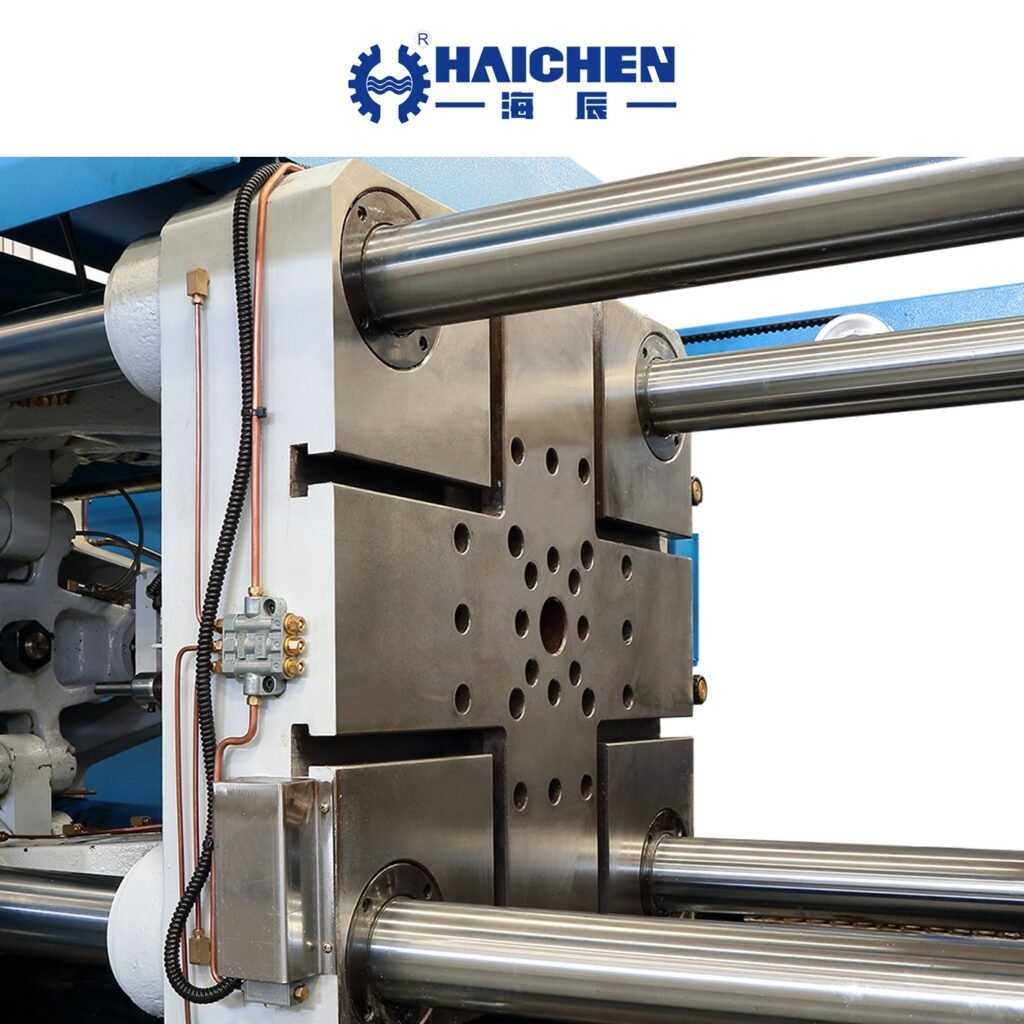

Preparing the Die Cavity

The operator prepares the mold cavity. The mold is made of two or more steel halves (usually high-strength tool steel) through precision machining, and these parts are combined to form the shape of the final product. The mold must be able to withstand high pressure (10-175 MPa/1,500-25,400 PSI) and high temperature (aluminum melts at about 650-700°C). To achieve this, a special lubricant (such as a water-based mold release agent) is sprayed on the surface of the cavity to control the mold temperature and ensure smooth demolding of the subsequent casting.

Heating the Metal

Workers place metal ingots (such as aluminum alloys) in a furnace and heat them until they are completely liquid. In the case of aluminum alloys, the temperature must reach a molten state of about 650-700°C (1200-1290°F). The molten metal is transferred to a holding furnace by a dosing spoon for use, and the temperature must be strictly controlled to avoid oxidation.

High-pressure Injection

The molten metal is injected into the closed mold cavity at high pressure (up to 20,000 PSI) through a hydraulic or mechanical system. High pressure forces the metal to quickly fill every detail of the cavity, ensuring that the casting has a complete outline and uniform wall thickness. Immediately after injection, the pressure is maintained to prevent metal backflow and compensate for solidification shrinkage.

Cooling and Solidification

After the mold is filled with molten metal, the operator needs to precisely control the cooling process. The cooling rate of the metal directly affects the grain structure and mechanical properties of the casting – rapid cooling can form finer grains, thereby improving the hardness and strength of the product. At this stage, the cooling liquid circulation channel built into the mold needs to achieve uniform heat dissipation to prevent thermal stress deformation caused by uneven temperature. The solidification time needs to be dynamically adjusted according to the thickness of the casting, the type of alloy and the temperature of the mold to ensure that the internal structure is intact and defect-free.

Ejection of the Casting

After the metal is completely solidified, the mold opens automatically. At this time, the demolding system (such as the ejector mechanism) pushes the casting out of the mold cavity, and the operator needs to simultaneously check whether the product is sticking or deformed. The mechanical action at the moment of demolding needs to be precisely coordinated with the opening and closing of the mold to avoid damaging the surface of the casting. Some products may have residual flash or gate residue, which needs to be cleaned immediately after removal.

Post-processing

The castings after demolding need to undergo multiple surface treatments:

- Trimming: Use mechanical cutting or stamping to remove metal burrs remaining in the pouring system;

- Grinding: Use grinding wheels or polishing equipment to eliminate parting line marks and improve surface finish;

- Defect repair: Repair welding or fill casting defects such as pores and cold shuts.

These operations are designed to meet the product dimensional accuracy and appearance requirements. Some high-precision castings also require rust prevention or dimensional calibration.

Inspection and quality control

Finally, the die castings need to undergo quality inspection after completion. This step is mainly to check whether the product meets the size and performance standards required by the customer.

Finishing touches

Depending on the actual use requirements, customers may also require additional surface treatment. Common treatments include painting, electroplating or anodizing, which can make the product more durable or better looking.

Quality Control and Inspection

Real-Time Monitoring

The sensors and automation systems we install on the production line can continuously track key data in the die-casting process, such as temperature, pressure and injection speed. These devices automatically record data and generate reports to help operators keep abreast of production dynamics.

When temperature fluctuations or insufficient injection pressure occur during the production process, the monitoring system will immediately issue an alarm.

In this way, the operator can intervene immediately and adjust the equipment parameters in time to ensure stable operation of the production process and stable product quality.

Finished Product Inspection

Dimension and appearance inspection

Use high-precision measuring tools (such as precision coordinate measuring machines) to check the dimensional accuracy of each part to ensure that it fully meets the requirements of the design drawings. At the same time, quality inspectors will carefully check for scratches, pores, shrinkage holes and other defects on the surface of the parts through visual inspection and surface roughness testers.

Internal structure inspection

For core parts involving safety performance, non-destructive testing technologies (such as X-ray fluoroscopy and ultrasonic scanning) are used. These technologies can accurately identify internal cracks, impurities or structural defects without damaging the parts, ensuring the durability and reliability of the parts from the source.

Closed-loop quality management

All test data are compare item by item with design specifications and industry quality standards. Parts that do not meet the standards will enter the rework process or be scrapped to ensure that the final products shipped meet customer requirements 100%. Quality inspectors will stamp and sign qualified products and update the inspection record sheet simultaneously to achieve full traceability.

Common Issues and Solutions

Porosity and Shrinkage

Cause analysis: Porosity and shrinkage are two common defects in the die casting process.

- Porosity is usually caused by two reasons: one is that the injection speed is too fast, causing the metal liquid to entrain with gas. Or the mold exhaust is not smooth, which hinders the gas discharge. The other is that the raw material has a high gas content (such as hydrogen dissolved in aluminum liquid). Or the smelting temperature is too high, which increases the gas solubility. Excessive use of release agent may also decompose and produce gas.

- Shrinkage is mainly caused by uneven mold temperature: local excessive temperature will lead to differences in cooling speed. And uneven volume shrinkage will form holes when the metal solidifies. In addition, excessive differences in casting wall thickness will aggravate uneven shrinkage.

Solution: Comprehensive improvements are required in terms of process parameters, mold design and new technologies.

Optimize process parameters:

- Injection control: Reduce the punch speed in the high-speed injection stage (recommended ≤0.5m/s) to avoid turbulent entrainment of metal liquid. Adjust the boost pressure and holding time to ensure that the metal liquid is fully filled before solidification.

- Temperature management: strictly control the melting temperature (avoid overheating) and degas the alloy liquid. Cool the mold to the working temperature range at the same time to ensure uniform mold temperature.

Improve mold design:

- Exhaust system: add exhaust grooves or exhaust plugs, and clean them regularly to prevent blockage. The total cross-sectional area of the overflow groove must be ≥ 60% of the cross-sectional area of the casting to facilitate gas discharge.

- Cooling system: optimize the layout of cooling water channels to avoid local overheating. Strengthen cooling of thick-walled areas to shorten solidification time.

Apply new technologies:

- Vacuum die casting: reduce the gas in the cavity by vacuuming, significantly reduce the porosity (can reduce the filling pressure by 30%-50%). And improve the density and mechanical properties of the casting.

- Material pretreatment: select low-gas alloys, add degassing agents during refining; use low-gas release agents and control the spraying amount.

Surface Defects

- Solutions:

- Regular mold maintenance: Establish an inspection plan to repair wear and scratches on the mold surface in a timely manner to ensure that the mold is in the best condition;

- Optimize lubrication management: Select high-quality mold lubricants and ensure that the lubricants evenly cover the mold surface through standardized operations;

- Surface strengthening treatment: Improve the quality of the mold surface through polishing or professional coating technology, which has a significant effect on improving the appearance of the part.

Insufficient Mechanical Properties

The problem of insufficient mechanical properties usually stems from three key links: material selection, cooling control or injection molding parameter setting. When the chemical composition or physical properties of the material do not match the design requirements, the strength, toughness and other indicators of the part will decrease. At the same time, cooling too fast or too slow will change the internal structure of the part, directly affecting the final performance.

We can improve it through the following measures:

- Optimize material formula: re-evaluate the material composition to ensure that its chemical composition and physical properties meet the design standards;

- Adjust process parameters: accurately control cooling time and injection molding pressure according to part thickness and structural complexity;

- Add post-processing steps: For example, heat treatment of key components can effectively improve surface hardness and fatigue resistance.

Die casting operation steps require strict adherence to multiple technical steps: first lubricate and close the mold. Then inject molten metal into the mold under high pressure. And remove the molded part after the metal cools and solidifies.

Mastering these specific operating procedures can help the production team optimize process parameters and ensure that the quality of parts is stable and meets the highest industry standards.