Die-cast aluminum cookware has become the latest favorite in modern kitchens since it conducts heat very well and remains light yet strong. Made by a process known as high-pressure die-casting, this cookware has an unbroken dense structure that allows heat to be distributed all over the surface—best used with cooking methods needing high temperatures, such as stir-frying and pan-searing.

Aluminum in its raw form can react with acidic ingredients leading to possible migration of aluminum ions into food with time thus posing health risks.

So, when you’re choosing die-cast aluminum cookware, focus on safety with the coating, good craftsmanship, and a brand you

Key Considerations for Selection

- Material and Craftsmanship: The Foundation of Durability

- Heat Conductivity and Retention: Efficiency in Cooking

- Coating and Safety: Guarding Against Health Risks

- Usage and Maintenance: Maximizing Lifespan

- Brand and Certifications: Ensuring Quality

- Additional Practical Factors

- Conclusion: Balancing Performance and Safety

Material and Craftsmanship: The Foundation of Durability

- High-Purity Aluminum vs. Recycled Aluminum: Opt for high-purity aluminum or silicon-enhanced alloys for enhanced hardness and corrosion resistance. Avoid recycled aluminum products, which may contain impurities like lead or cadmium.

- Advantages of Die-Casting: The high-pressure die-casting process eliminates seams and rivets (e.g., one-piece designs), reducing food residue buildup. Compared to forged aluminum, die-cast aluminum heats more evenly but is slightly heavier.

Heat Conductivity and Retention: Efficiency in Cooking

- Rapid Heat Transfer: Die-cast aluminum conducts heat 3x faster than cast iron, perfect for quick-heating tasks like sautéing. For prolonged heat retention, choose cookware with thickened bases (≥3mm).

- Versatile Heat Source Compatibility: Look for an “Induction Ready” label to ensure compatibility with gas, induction, and oven use (check temperature limits).

Coating and Safety: Guarding Against Health Risks

- Coating Types and Certifications:

- PTFE (Teflon™): Must be certified free of PFOA and heavy metals (e.g., DuPont coatings with FDA/ISO certifications).

- Ceramic/Marble Coatings: Natural, non-toxic, and heat-resistant (up to 400°C), though less scratch-resistant.

- Anti-Aluminum Leakage Design: Anodized treatments or dense coatings prevent direct contact between aluminum and food. Avoid uncoated or poorly coated products.

Usage and Maintenance: Maximizing Lifespan

- Temperature Control: Use at medium-low heat (≤240°C). Avoid preheating empty cookware or prolonged high heat (e.g., searing steak), which may degrade coatings. Opt for cast iron for high-heat tasks.

- Cleaning and Care:

- Use silicone or wooden utensils to avoid scratching coatings; never use metal tools or abrasive scrubbers.

- Hand wash gently with mild detergent; avoid dishwashers and harsh cleaners.

- Dry thoroughly and store with soft padding to prevent scratches.

Brand and Certifications: Ensuring Quality

- Trusted Brands: Established brands like Griswold and Calphalon undergo rigorous testing for decades-long durability.

- Certifications: Prioritize products with FDA (food safety), ISO 9001 (manufacturing standards), and UL (material safety) certifications.

Additional Practical Factors

- Weight and Ergonomics: Die-cast aluminum is 30-40% lighter than cast iron. Choose models with heat-resistant handles (silicone or double-layered designs) for comfort.

- Multifunctionality: Some products are oven-safe (≤260°C) or dishwasher-friendly—verify labels before purchase.

Conclusion: Balancing Performance and Safety

Die-cast aluminum cookware excels in speed and efficiency, but mitigate risks by:

- Prioritizing Materials: Choose high-purity aluminum with certified safe coatings.

- Verifying Certifications: Ensure coatings meet international safety standards to block aluminum migration.

- Following Usage Guidelines: Control heat, avoid abrasives, and maintain proper storage.

- Choosing Reputable Brands: Trust brands with proven track records in craftsmanship and customer support.

For those concerned about aluminum exposure, opt for anodized aluminum cookware (with a protective oxide layer) or ceramic-coated aluminum pots to further minimize risks.

Haichen Cookware die casting machine

Haichen Cookware, as a professional manufacturer of die casting machines, offers cold chamber die casting machines widely used in the production of aluminum alloy cookware (such as pots, frying pans, etc.). Below are the key details:

- Technical Features & Applicability

- Core Advantages

- Application Cases

- Services & Certifications

- Comparison with Competitors

Technical Features & Applicability

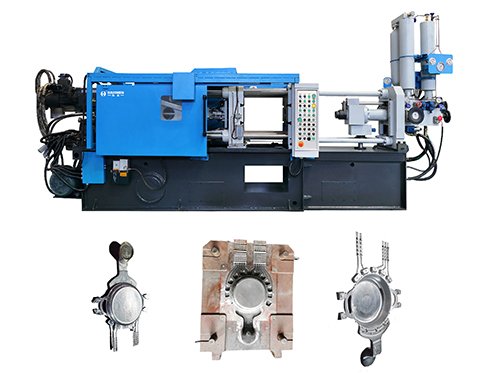

- Cold Chamber Die Casting Machines: Designed specifically for aluminum alloys, Haichen’s machines utilize high-pressure injection technology (8 m/s injection speed) to rapidly fill molds with molten aluminum, ensuring high-density, high-precision cookware components. For example, the 580-ton model (HCD580-C) can produce pots and frying pans, with a clamping force of 5,800 kN, ideal for large-scale production of oversized cookware.

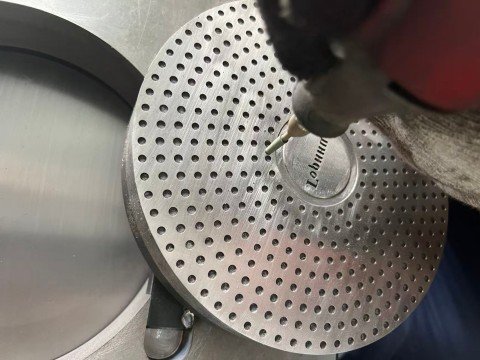

- Customizable Molds: Supports interchangeable molds for diverse cookware designs (e.g., saucepans, skillets) to meet varied market demands.

- Automated Production Lines: Integrated with robots, spraying systems, and vacuum systems, enabling fully automated processes from melting to finished products, boosting efficiency.

Core Advantages

- Energy Efficiency: Servo hydraulic systems and real-time control technology reduce energy consumption by 30–50% while maintaining high-speed production (e.g., 8 m/s clamping speed for 90-ton models).

- Quality Assurance: ISO 9001 and CE certified. Equipped with real-time temperature monitoring (thermocouples) and pressure sensors to ensure defect-free castings with smooth surfaces, minimizing post-processing.

- Flexible Configurations: Clamping forces range from 350 kN to 20,800 kN (38 to 2,080 tons), accommodating small items (e.g., medals) to large automotive parts, ideal for cookware of all sizes.

Application Cases

- Aluminum Pot Production: The 580-ton model specializes in pots and pans, producing uniform wall thickness for stable heat distribution and reduced deformation.

- Integrated Production: Similar to Tesla’s approach, Haichen supports “integrated die casting” to eliminate welding points, enhancing structural strength (e.g., one-piece body and handle).

Services & Certifications

- Global Reach: Exports to India, Russia, Mexico, and more, providing turnkey solutions for international cookware brands.

- Technical Support: Offers mold design, mold-flow analysis, and equipment configuration guidance to optimize production costs.

Comparison with Competitors

- While brands like Hawkins use die casting, they rarely disclose machine suppliers. Haichen, as a direct manufacturer, offers transparent technology and customization, giving it a supply chain edge.

Haichen’s cold chamber die casting machines excel in efficiency, precision, and flexibility, making them ideal for mass-producing high-quality aluminum cookware like pots and frying pans. Their energy-saving design and integrated automation cater to manufacturers prioritizing cost-effectiveness and scalability.