Die casting of crankcases is a form of metal casting that enables the inclusion of vital moving components like crankshafts, connecting rods, and pistons into the engine.

Crankcases are built with a specific metal alloy which makes them light, robust, and resistant to corrosion, and is thus extensively used in manufacturing motorcycles, agricultural machinery, and tools associated with industrial work.

Using technology such as High Pressure Die Casting, die casting crankcases can be produced at scale. This procedure entails pouring molten metal (like aluminum alloy) into a mold under high pressure. As the metal cools rapidly, it assumes the shape of the mold. This specific procedure is known for its high speed and accuracy when it comes to production, and it also helps minimize material waste and further processing costs.

In die casting machines, die casting machine crankcase types mainly divided into the following 5 types:

- Aluminum alloy die casting crankcase

- Magnesium alloy die casting crankcase

- Zinc alloy die-cast crankcase

- Cast iron die-cast crankcase

- Combination die-cast crankcases

Aluminum alloy die casting crankcase

- Material selection for aluminum alloy die-casting crankcase

- ADC12

- AlSi9Cu3

- A380

- Application of aluminum alloy die-casting crankcase

Aluminum Alloy Die Casting Crankcase is a critical component in automotive engines, primarily responsible for accommodating components such as the crankshaft, gearbox, and oil pump, and providing lubrication and cooling during engine operation.

Material selection for aluminum alloy die-casting crankcase

Aluminum alloy widely use in the manufacture of crankcases for automotive engines. Due to its lightweight, high strength, and excellent casting performance. Common aluminum alloys include:

ADC12

A commonly used die cast aluminum alloy with excellent casting and mechanical properties, suitable for the manufacture of crankcases.

AlSi9Cu3

It has high hardness and wear resistance, suitable for components that require high pressure sealing.

A380

A universal aluminum alloy that balances casting and mechanical properties, suitable for various automotive components.

The selection of these alloys depends on specific application requirements. Such as whether it requires high heat resistance, wear resistance, or corrosion resistance.

Application of aluminum alloy die-casting crankcase

Aluminum alloy die-casting crankcases widely use in automotive engines, motorcycle engines, and industrial equipment.

- Automotive engine: Aluminum alloy die-casting crankcase widely uses in modern automotive engines due to its lightweight and high strength.

- Motorcycle engine: Aluminum alloy die-casting crankcases also widely use in motorcycle engines. Especially in high-performance motorcycles, where aluminum alloy die-casting crankcases can reduce weight and improve performance.

- Industrial equipment: Aluminum alloy die-casting crankcases also use in industrial equipment such as gearboxes, clutch housings, etc.

Magnesium alloy die casting crankcase

- Material selection and performance optimization

- The application of magnesium alloy die-casting crankcases

Due to its lighter weight and lower moment of inertia, magnesium alloy has gradually replaced aluminum alloy in some high-performance applications in recent years.

Material selection and performance optimization

Magnesium alloy die-casting crankcases usually use magnesium aluminum alloys (such as AM60B, AZ91D, etc.) as the substrate. These alloys have high specific strength (strength/weight ratio), as well as good casting performance and corrosion resistance.

For example, after adding rare earth elements (RE), the microstructure of AM60B alloy is refined. With an average grain size reduced from 39 μ m to 20 μ m, it significantly improves Brinell hardness, impact toughness, and fatigue performance. In addition, the addition of rare earth elements not only improves the mechanical properties of the alloy, but also enhances its stability in high-temperature environments.

The application of magnesium alloy die-casting crankcases

In the automotive industry it mainly includes:

- Engine components: such as crankcase, cylinder block, cylinder head, etc., used to improve the lightweight and efficiency of the engine.

- Chassis components: such as steering column, suspension system, transmission shaft, etc., They use to improve the handling and stability of the vehicle.

- Interior components: such as instrument panel, door panel, center console, etc., used to reduce body weight and improve comfort.

- Aerospace: components such as auxiliary gearboxes, generator housings, engine hoods, etc., used for high-precision and high reliability requirements.

Zinc alloy die-cast crankcase

- Material characteristics

- The die-casting process of zinc alloy has the following advantages

Zinc alloys are often use in applications that require higher strength and corrosion resistance. Such as housings for electronic products or parts of some industrial equipment.

Material characteristics

Zinc alloys, especially the Zamak series normally uses in the manufacturing of crankcases due to their excellent mechanical and processing properties.

For example, Zamak 3, Zamak 5, and Zamak 7 are common zinc alloys that have high strength, hardness, and corrosion resistance, as well as good casting performance and surface treatment ability. In addition, ZA series alloys (such as ZA-8, ZA-12, and ZA-27) further enhance their strength and wear resistance by increasing the content of aluminum and copper

The die-casting process of zinc alloy has the following advantages

- High fluidity: Zinc alloy has good fluidity during the casting process and can fill complex mold structures, thereby achieving high-precision castings.

- Low melting point: Zinc has a low melting point (about 380-400 ° C), which reduces the temperature required during the casting process, thereby reducing thermal stress and wear on the mold and extending its lifespan.

- High dimensional accuracy: Zinc alloy die-casting parts have high dimensional accuracy, usually reaching close to net size, reducing the need for subsequent processing.

- Good surface quality: Zinc alloy die-casting parts have a smooth surface and do not require excessive secondary processing. They can directly electroplate or spray.

Cast iron die-cast crankcase

- Material selection and structural design

- Manufacturing process

Cast iron uses in some heavy machinery or special purpose engines because of its high strength and wear resistance.

Material selection and structural design

Cast iron die-casting crankcases typically use gray cast iron as the cylinder body material due to its excellent strength, wear resistance, and cost-effectiveness. During the high-pressure die-casting process, cast iron cylinder liners are embedded into aluminum crankcases to provide necessary rigidity and durability.

Manufacturing process

The manufacturing of cast iron die-casting crankcases usually adopts high-pressure die casting or gravity die casting processes. High pressure die casting can achieve more complex shapes and higher precision, while gravity die casting is suitable for certain specific production needs.

Haichen Optimize Crankshaft Housing Design Based on Equipment Type

Haichen scientifically applies two types of die-casting machine crankshaft housings according to the positioning and target markets of different series, optimizing equipment performance.

Project Background and Design Objectives

To meet the extreme demands for high dynamic precision and stability in new energy vehicle structural components, Haichen plans to develop a new generation of ultra-large die-casting machines.

Haichen’s Crankshaft Housing Selection and Engineering Design

Despite its massive tonnage, Haichen’s engineering team innovatively adopted an “integrated frame” combined with “separate casting and on-site precision assembly” to pursue extreme rigidity. Core load-bearing components underwent finite element optimization design and were connected using patented stress diffusion and homogenization technology.

Technical Advantages and Customer Value Achieved

This design preserves the manufacturability benefits of a split structure while achieving rigidity approaching that of an integral structure. In actual operation, it demonstrates exceptional mold-closing parallelism and injection stability, meeting customer requirements for high consistency in large structural component production.

Market Feedback

Haichen’s ultra-large die-casting machines employing this design have been successfully delivered to multiple customers. Their outstanding stability and low failure rate have earned market recognition.

Combination die-cast crankcases

Some complex designs may require a combination of multiple materials to optimize performance.

For example, the crankcase of some engines may contain a combination of aluminum alloy body and cast iron liner.

These different die casting machine crankcase types are suitable for different application scenarios based on their material properties and manufacturing processes, thereby meeting specific performance requirements.

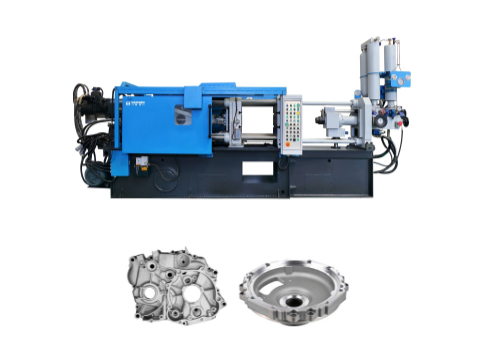

Haichen crankcase die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features. Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

Haichen have rich experience of manufacturing aluminium crankcase die casting machine. As per each customer’s specific demand, we can also supply aluminium alloy, magnesium or zinc alloy crankcase production line. Also with auto ladle, auto sprayer and other necessary auxiliary equipment to improve the production efficiency and products quality.