Die casting mould materials types mainly includes tool steel, alloy steel, mold steel, stainless steel and others.

Die casting mould is a precision casting tool used to inject molten metal into the mold cavity under high pressure. Allowing it to quickly cool and solidify into shape. Its basic definition is that die casting molds are key process equipment in die-casting production. It injects liquid metal into the mold cavity through high pressure. To form castings with complex shapes and thin-walled cross-sections.

Die casting molds usually consist of two parts, namely a fixed mold half and a movable mold half, which are connected at the mold opening and closing line. Used to form the internal and external structure of castings.

Die casting mold materials need to have characteristics such as high temperature resistance, high wear resistance, and heat fatigue resistance. The selection of die casting mold materials is critical because they need to withstand high temperature and high pressure environments. According to the evidence, commonly used die casting mold materials include the following:

- Tool Steel

- Alloy Steel

- Mold Steel

- Stainless Steel

- Bronze

Tool Steel of die casting mould materials types

- Hot work tool steel

- Cold work tool steel

- Pre hardened tool steel

- High purity tool steel

- Tool steel physical and chemical properties

Tool steel is commonly uses mold material with high strength and wear resistance, suitable for manufacturing high-quality die casting molds.

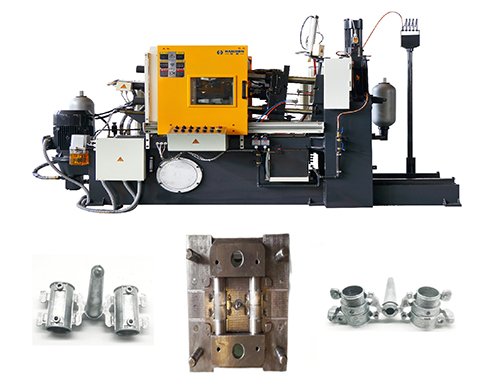

Haichen is a well-known manufacturer of high-pressure die casting (HPDC) machines, based in China. The company produces a wide range of die casting machines and die cating mould including cold chamber and hot chamber die casting machines. The machines cater to various industries, including automotive, electronics, home appliances, and more. Haichen’s machines are known for their reliability, efficiency, and advanced technology.

The application types of tool steel in die-casting molds mainly include the following:

Hot work tool steel

This type of tool steel is mainly used for die-casting molds that can withstand high temperatures and pressures, and has good heat resistance, wear resistance, and thermal fatigue resistance. Common hot work die steels include H13, 2343/H11, W350/TQ1, 8407, DIEVAR, etc. For example, H13 steel is widely used in die-casting molds for aluminum, zinc, and magnesium due to its excellent red hardness and resistance to thermal cracking. DIEVAR, on the other hand, is particularly suitable for high demand hot work applications such as die-casting, forging, and extrusion due to its excellent toughness, ductility, and resistance to thermal cracking.

Cold work tool steel

Although mainly used for cold processing, some tool steels are also suitable for hot work molds. For example, 5Cr4Mo-3SiMnVAl steel has high strength and toughness, good heat resistance and thermal fatigue resistance, and is suitable for cold forging dies, punching dies, slot bolt hot forging dies, hot extrusion punches, etc.

Pre hardened tool steel

This type of tool steel is pre hardened at the factory and does not require further heat treatment. It is suitable for die-casting molds that require rapid manufacturing and high precision. For example, TOOLOX 44 is a pre hardened tool steel with the same hardness (45 HRC). Through alloying and final hardness treatment controlled by the steel manufacturer, important properties such as impact toughness, tensile strength, and thermal fatigue can be better controlled.

High purity tool steel

such as TQ1 and CS1, has excellent high-temperature strength, toughness, heat crack resistance, and thermal conductivity, making it suitable for applications with high requirements for casting molds, such as automotive structural components, radiator fins, and transmission die-casting molds.

Tool steel physical and chemical properties

There are significant differences in the physical and chemical properties of various tool steels in die-casting molds, mainly reflected in heat resistance, wear resistance, thermal fatigue resistance, impact toughness, hardness, and other aspects.

- 3Cr2W8V steel: it is suitable for manufacturing various types of die-casting molds, especially in situations where high temperature strength and wear resistance are required. For example, it is commonly used to manufacture copper alloy extrusion dies, convex and concave dies on forging machines, inserts, etc.

- H13 steel: it widely uses in die-casting molds due to its excellent heat resistance and wear resistance, suitable for manufacturing complex shaped die-casting molds. H13 steel is also suitable for die-casting molds of aluminum, zinc, magnesium, and copper alloys.

- 2343/H11: this one is suitable for large molds, with the characteristics of low segregation rate, high toughness, and high thermal conductivity.

Alloy Steel

- Alloy steel scope of application

- The specific application types of alloy steel

Alloy steel is usually used for molds that require higher strength and durability. For example, 4140 alloy steel and P20 alloy steel often use to make the cavity part of the die casting mold, while H13 alloy steel uses to make the fixed part of the mold.

Alloy steel scope of application

Aluminum alloy die-casting molds: Alloy steel is suitable for manufacturing aluminum alloy die-casting molds, especially materials such as 3Cr2W8V, H13, etc.

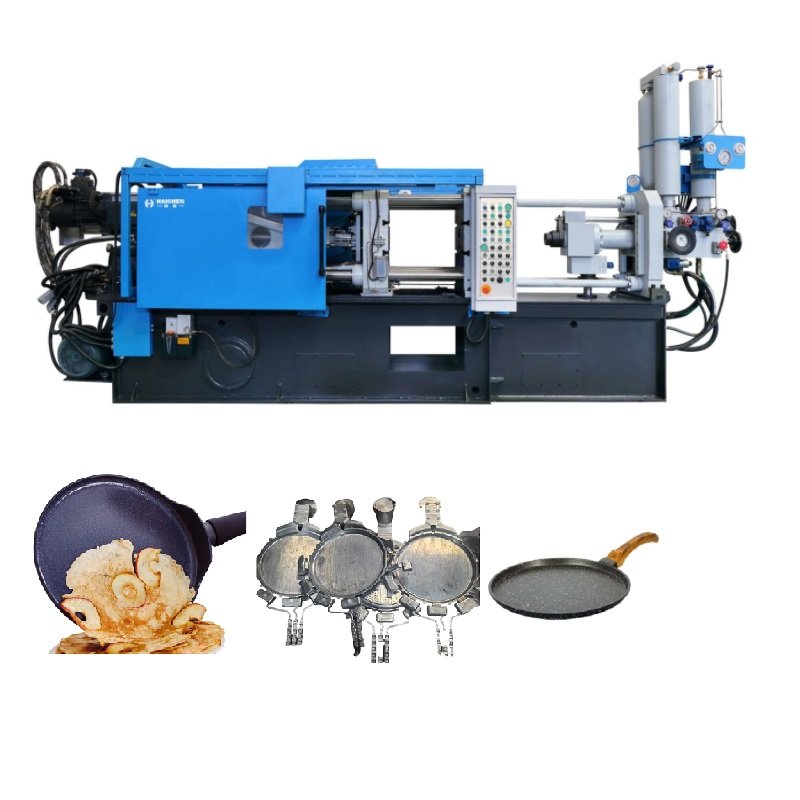

For example, with aluminum alloys die catsing mould, Haichen design and produce for aluminum alloy pizza pan cookware pot. We can design replaceable pot bottom moulds for same diameter with different bottom shape pans. That can help save and reduce customer’s significant cost.

Zinc alloy die-casting molds: Alloy steels such as SKD61 and 2344 are suitable for zinc alloy die-casting molds.

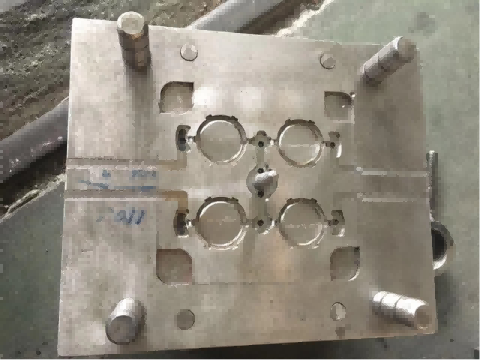

For example, Haichen uses zinc alloys material to produce medals die casting mold and zinc alloy pipe fitting couplings die casting mould. Please see attached these Haichen die casting molds photos.

Magnesium alloy die-casting molds: Alloy steel is suitable for magnesium alloy die-casting molds, especially for applications that require high thermal stability and wear resistance.

The specific application types of alloy steel

In die-casting, alloy steel mould material mainly include

- 4Cr5MoSiV1 steel: This alloy steel exhibits excellent high-temperature strength and thermal fatigue resistance in die-casting molds, and is suitable for manufacturing aluminum alloy die-casting molds.

- 8407 steel: 8407 steel is an advanced die-casting mold steel with good resistance to mechanical fatigue, thermal stress fatigue, and corrosion, suitable for manufacturing aluminum alloy die-casting molds.

- QRO90S steel: QRO90S steel has excellent high-temperature yield strength and tempering resistance, suitable for manufacturing die-casting molds for copper and brass.

Mold Steel

- Cold work mold steel

- Hot work mold steel

- High alloy mold steel

Mold steel is a high-strength steel specially designed for making molds, usually used to make molds with a long life. For example, mold steel can reach HRC40-46 hardness, with good wear resistance and impact resistance. With suitable die casting material, it can produce higher quality metal products.

The specific application scenarios of different mold steels in practical applications are as follows:

Cold work mold steel

mainly used to manufacture molds for pressing and forming workpieces in a cold state, such as punching molds, cold drawing deep molds, embossing molds, etc. This type of mold steel requires high hardness, strength, wear resistance, and toughness. High carbon alloy steels such as Cr12MoV, D2, SKD11, etc. are commonly used.

Hot work mold steel

mainly used for manufacturing molds for pressure processing of workpieces under high temperature conditions, such as hot forging molds, hot extrusion molds, die-casting molds, etc. This type of mold steel needs to have good high-temperature strength, thermal stability, wear resistance, and thermal fatigue resistance. Commonly used alloying elements include Cr, W, Mo, V, etc. Representative steel grades include H13, 3Cr2W8V, 5CrNiMo, etc.

High alloy mold steel

such as 8407, S136, SKD61, DC53, etc., suitable for various metal sheets, with good dimensional stability, surface treatment performance, and processing performance.

Stainless Steel

- Hardness and strength

- Corrosion resistance

Stainless steel uses in mold manufacturing under certain specific conditions due to its good corrosion resistance and thermal stability. For example, stainless steel is a good choice for molds that need to be corrosion-resistant or work in high-temperature environments.

Hardness and strength

The hardness and strength of different stainless steel grades vary greatly. For example, 1Cr18Ni9Ti (Chinese grade) has high hardness and wear resistance, making it suitable for manufacturing molds with high requirements. Such as plastic injection molds, die-casting molds, etc.

- The yield strength of 304 stainless steel is 205 MPa.

- The tensile strength is 515 MPa

- The elongation is 40%, the Brinell hardness is 201

- The Rockwell hardness B is 92.

These parameters indicate that 304 stainless steel performs well in general applications, but may not be as good as other grades in high temperature or high corrosion environments.

Corrosion resistance

The corrosion resistance of stainless steel is closely related to its chemical composition. For example, 1.4404 (316L) and 1.4571 (316Ti) have similar corrosion characteristics, but 1.4571 is more sensitive to pitting corrosion and has poorer stability against stress corrosion cracking and intergranular corrosion caused by chloride. In contrast, 1Cr18Ni9Ti exhibits better corrosion resistance in chemical equipment and medical devices

Bronze

Bronze is an alloy with good thermal conductivity and corrosion resistance. It is suitable for some special applications, such as molds that require rapid cooling.

Therefore, choosing the right mold material is crucial to ensure the quality of die-casting products and the durability of the mold. Each material has its specific application scenarios and advantages and disadvantages, so you need to select according to specific needs in actual applications.