Die casting alloys applications are in many industries like automotive industry, aerospace industry, consumer electronics and other industries.

Die casting is a process widely uses in multiple manufacturing industries to produce metal parts with complex geometry, high precision and good surface quality. The application areas of die casting are very wide, covering a variety of industries from automobiles, electronics to household appliances.

Die casting alloys application mainly use in below 6 aspects:

- Automotive industry

- Aerospace industry

- Consumer electronics

- Home appliances

- Lighting and electrical industry

- Medical equipment

Die casting alloys application: automotive industry

In the automotive industry, die-casting alloys (especially aluminum and magnesium alloys) are widely used. They mainly due to their lightweight, high strength, high precision, and good processing performance. The following is a detailed analysis of the application of die-casting alloys in the automotive industry:

Die casting wide uses in the automotive industry, mainly for the production of engine parts. Such as engine blocks, cylinder heads, crankcase transmission housings. And structural parts (such as frames, brackets and suspension parts) and decorative parts (such as logos, decorative strips and handles).

Lightweight and Energy Efficiency

Die cast alloys, such as aluminum and magnesium alloys, have become important materials for automotive lightweighting due to their low density and high specific strength. Lightweight not only helps reduce the overall weight of the vehicle, but also significantly improves fuel efficiency and reduces emissions. For example, research has shown that reducing a car’s weight by 10% can increase its range by 5-6%.

In addition, with the rise of electric vehicles (EVs), the weight of battery packs and electric drive systems has increased, leading to a further increase in demand for lightweight materials. The application of aluminum alloy and magnesium alloys in key components such as battery casings and motor casings can help improve the range and energy efficiency of electric vehicles.

Complex structures and high-precision manufacturing

Die casting technology can produce components with complex geometric shapes and high-precision requirements, which are difficult to achieve with traditional casting and forging processes. For example, die casting techniques can be used to manufacture engine cylinder blocks, gearbox housings, steering system components, and brake systems. These components require precise dimensions and surface quality to ensure their high-performance performance in automobiles.

High strength and corrosion resistance

Aluminum and magnesium alloys have excellent mechanical properties and corrosion resistance, making them ideal choices for key automotive components. For example, aluminum silicon alloys (such as A356) are widely used in automotive engines and chassis components due to their excellent casting performance and corrosion resistance.

Magnesium alloy is used to manufacture lightweight body structures and interior parts due to its higher strength and lower density.

Die casting alloys application: Aerospace industry

Die casting uses in the aerospace sector to manufacture lightweight and high-strength components such as turbine blades, fan casings and aircraft structures.

It also uses to produce housings for avionics equipment and parts for military equipment.

lightweight design

One of the core advantages of die-casting technology in the aerospace industry is its ability to achieve lightweight design. Aluminum and magnesium alloys are ideal choices for aerospace components due to their excellent strength to weight ratio. For example, aluminum silicon alloys (such as ADC12, A380) and magnesium alloys (such as AZ91D) can be used in the die-casting process to manufacture lightweight but high-strength components, significantly reducing the total weight of the aircraft, improving fuel efficiency and flight performance.

Manufacturing of complex geometric shapes

Die casting technology can produce parts with complex geometric shapes, including thin-walled structures and fine details. This ability enables die-casting technology to manufacture components in the aerospace industry that are difficult to achieve with traditional casting processes, such as wing ribs, brackets, engine casings, etc.

High precision and surface quality

Die casting technology can achieve high-precision dimensional control and good surface quality. This enables die-casting components to meet strict assembly and functional requirements in the aerospace industry. For example, aluminum die castings typically have high dimensional accuracy (up to level 4) and low surface roughness (up to level 5), and can be used directly without further processing.

Die casting alloys application: Consumer electronics

Die casting uses in the consumer electronics industry to produce electronic equipment housings, aluminium radiator, heat sinks, connectors and other parts.

Shell and structural components

Die casting technology can produce lightweight, high-strength casings and structural components, such as casings for smartphones, laptops, tablets, etc. These shells not only need to have good mechanical strength, but also need to have good heat dissipation performance. For example, aluminum silicon alloys (such as A380, A383) are widely used in the manufacture of electronic device casings due to their excellent thermal conductivity and corrosion resistance.

In addition, magnesium alloys such as AZ91 are also used to manufacture casings for devices such as mobile phones and cameras due to their lightweight and high-strength characteristics.

Radiators and Thermal Management Systems

Die casting technology also plays an important role in the thermal management system of electronic devices. Aluminum alloy and magnesium alloy have excellent thermal conductivity, which can quickly dissipate the heat inside the equipment to the external environment. For example, aluminum silicon alloy is commonly used to manufacture fins and fins for heat sinks to improve heat dissipation efficiency. In addition, die-casting technology can directly integrate heat dissipation channels into structural components, thereby reducing reliance on additional cooling systems

Due to its high precision and excellent thermal management performance, die-cast aluminum products are particularly suitable for applications that require heat dissipation.

Home appliances

Die casting widely uses in the production of home appliances, including structural components and housings of refrigerators, washing machines, coffee machines, door handles, etc.

This process ensures product durability and assembly accuracy.

Household appliance casing

Die cast aluminum is widely used to manufacture the casing of household appliances, such as refrigerators, washing machines, air conditioners, etc. The lightweight characteristics of aluminum not only reduce the overall weight of the product, but also improve its aesthetics and durability. Meanwhile, aluminum has good thermal conductivity, which helps with heat dissipation inside household appliances.

Internal structural components of household appliances

Die cast aluminum is also used to manufacture internal structural components of household appliances, such as brackets, gearboxes, motor components, etc. These components require high strength and good mechanical properties, and die cast aluminum can meet these requirements.

Kitchen utensils

Die cast aluminum is also widely used in kitchen utensils, such as baking pans, frying pans, milk pots, etc. The corrosion resistance and good thermal conductivity of aluminum make it an ideal material for manufacturing these tools.

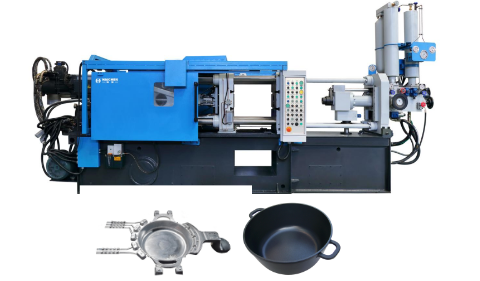

Haichen aluminium alloy cookware

For example, with aluminum alloy, Haichen produce high-output of aluminium cookware handles.

By design 12cav aluminum pan handle mould, to meet customer increasing production requirment.

Moreover, Haichen use aluminum alloys material to produce aluminum alloy pot, alumnium alloy pan. We can design replaceable pot, rechangable pan bottom moulds for same diameter with different bottom shape pans. Through Haichen adavanced aluminium die casting technology, and with Haichen high pressure cold chamber die casting machine.That can help save and reduce customer’s significant cost.

Haichen is a well-known manufacturer of high-pressure die casting (HPDC) machines, based in China. The company produces a wide range of die casting machines including cold chamber and hot chamber die casting machines. The machines cater to various industries, including automotive, electronics, home appliances, and more. Haichen’s machines are known for their reliability, efficiency, and advanced technology.

Home appliance accessories

Die cast aluminum is also used to manufacture accessories for home appliances, such as door handles, locks, regulators, gas valves, etc. These accessories need to have good wear resistance and corrosion resistance, and die cast aluminum can provide these properties.

Lighting and electrical industry

Die casting uses in the lighting industry to produce lamp holders, lamp housings and heat sinks.

Especially in high-power LED lighting applications, where its excellent heat dissipation properties make it an ideal choice. In addition, it also uses in switchgear, panel boards and circuit breakers for electrical equipment.

LED lighting casing

LED lighting is one of the important application areas of die-casting technology. Die cast aluminum parts can be used to manufacture the casing of LED lights, which require good heat dissipation performance and structural strength. Due to the high thermal conductivity of aluminum, die cast aluminum parts can effectively dissipate the heat generated by LED lights, thereby extending the service life of the lamps and improving their efficiency. In addition, die-casting technology can achieve the manufacturing of complex shapes, making the design of LED lamp shells more diverse and beautiful.

Lamp holder and connector

Die cast aluminum components also play an important role in the connection parts of lighting fixtures. For example, components such as lamp sockets, wiring terminals, and power connectors are usually manufactured using die-casting technology. These components need to have good conductivity and mechanical strength to ensure the safe and reliable electrical connection of the lamp. At the same time, die-casting technology can achieve high-precision size control, meeting the demand for miniaturization and precision in modern lighting fixtures.

Traffic signal lights

In the field of traffic signal lights, die cast aluminum parts are widely used to manufacture lampshades and casings. Due to the lightweight and corrosion resistance of aluminum, die cast aluminum parts can effectively reduce the weight of traffic lights and improve their durability in outdoor environments. In addition, the high reflectivity of aluminum helps to improve the brightness of LED light sources, allowing traffic signals to be clearly visible at night or in adverse weather conditions.

Medical equipment

Die casting is used in the medical industry to produce key components such as surgical instruments, hospital equipment, hospital bed gearboxes, etc.

Commonly used aluminum alloy materials such as A360 and A380 are widely used due to their excellent mechanical properties.

Aluminum die-casting alloys have become the preferred material in medical equipment manufacturing due to their lightweight, high strength, good thermal conductivity, and corrosion resistance.

Surgical instruments

Aluminum die-casting can produce lightweight and precise surgical tools such as bone plates, clamps, surgical forceps, etc. These tools have good biocompatibility and durability.

Imaging equipment

Aluminum die-casting is used to manufacture shells and brackets for X-ray and ultrasonic systems, which require high precision and good thermal stability.

Patient monitor

Aluminum die-casting is used to manufacture the casing and internal structure of the monitor, which requires lightweight and easy operation.

Hospital bed gearbox

Aluminum die-casting is used to manufacture gearboxes for hospital beds, which require high strength and lightweight components.

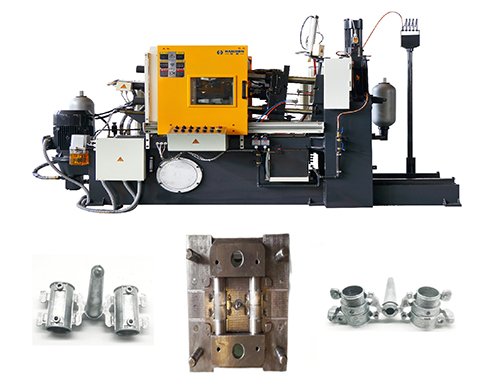

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We have many successfuly die casting alloy cases, such as zinc alloy pipe fitting, zinc alloy medals, aluminium pot and so on for selection. Welcome contact us for further details. We can supply production line according to our customer’s specific demand.