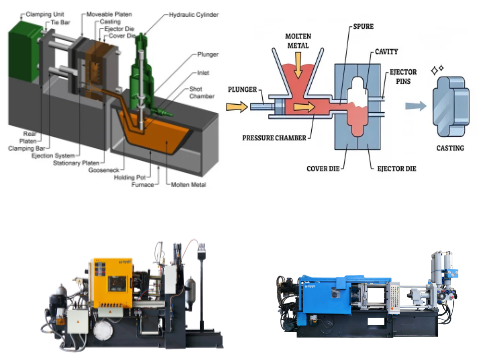

The fundamentals of die casting mainly includes the following steps:

- Mould clamping

- Injection

- Cooling and solidification

Die Casting is a metal forming process that uses the basic fundamentals of injecting molten metal under high pressure into a cavity called a mold, allowing it to cool and solidify into the desired shape.

Die casting is an efficient metal casting processing method that involves injecting molten metal into specialized molds to manufacture components with high precision and durability.

Haichen will explore the core principles, materials used, and the intricacies of die casting to provide you with a thorough understanding of this manufacturing technique.

What is Die Casting?

Die casting is a manufacturing process that allows the production of metal parts with a high degree of precision.

In this casting process, workers inject molten metal into a mould; subsequently, the metal cools and hardens within this cavity to form the desired shape.

Moreover, this method enables manufacturers to create diverse metal components, such as gears, engine blocks, door handles, and electrical parts.

Fundamentals of die casting——Mould clamping

- Prevent mold separation

- Hydraulic drive and locking mechanism

- Application of the clamping system

Prevent mold separation

During the die casting process, injecting high-pressure molten metal into the mold generates enormous pressure—for example, the high pressure from molten aluminum.

If the mold clamping is insufficient, it may cause mold separation, leakage of the metal liquid, casting defects and even equipment damage.

Therefore, the clamping system must deliver sufficient clamping force (typically measured in kilonewtons) to withstand the high pressure.

Hydraulic drive and locking mechanism

The clamping of molds is usually driven by a hydraulic system, which is achieved through hydraulic cylinders or mechanical locking mechanisms.

For instance, the positive mode locking system generates locking force through hydraulic cylinders, or uses wedge locking systems, double rocker systems, and other structures.

The hydraulic system transmits power through hydraulic pressure to achieve rapid clamping and release of the molds.

Application of the clamping system

In industries such as injection molding and die casting, manufacturers widely use the clamping mechanism to install, disassemble, and secure molds.

For instance, hydraulic or mechanical locking mechanisms enable the rapid positioning and locking of molds.

The clamping mechanism of the die-casting machine closes the moving and fixed moulds of the mould to form a sealed cavity.

This step ensures that the mould does not swell during the injection filling process.

Fundamentals of die casting——Injection

- Slow Injection

- Rapid injection

The injection mechanism injects molten metal into the cavity of the mould at high speed and pressure.

Slow Injection

where the system hydraulic oil pushes the injection piston to the left to achieve a slow injection process with the aim of removing air from the ballast chamber and preventing the molten metal from splashing out of the gate.

Rapid injection

When the injection punch exceeds the barrel pouring port, the hydraulic oil quickly enters the cavity.

So that faster injection, molten metal quickly fills the mold cavity.

The third stage,pressurization movement, the molten metal begins to solidify, the forward resistance of the punch increases.

At this time, the push of the hydraulic oil completes the pressurization process of the pressurized piston, and the molten metal cools and solidifies.

Fundamentals of die casting——Cooling & Solidification

- Cooling

- Solidification

- The role of the cooling system

Cooling

The molten metal cools and solidifies rapidly in the mold to form the desired casting.

Open the mold and the ejection mechanism ejects the casting from the mold to complete the die casting cycle.

After the molten metal enters the mold, it cools rapidly in contact with the mold wall, accelerating heat dissipation through cooling systems inside the mold.

Such as cooling water circulation, to shorten the solidification time. The cooling rate affects the structure and properties of the casting.

Solidification

The metal gradually cools and solidifies in the mold, forming the casting shape.

During solidification, the mold is clamped at high pressure to prevent defects (e.g., shrinkage, cracks) caused by metal shrinkage.

The role of the cooling system

Cooling channels or cooling channels are often included in mold design to remove heat by circulating cooling water, maintaining stable mold temperature, improving cooling efficiency, and extending mold life.

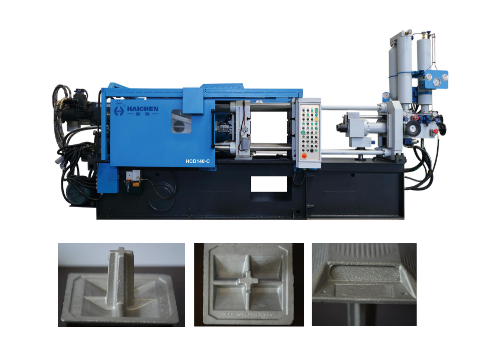

The machines required for the die casting——Die casting machines

- Hot chamber die casting machines

- cold chamber die casting machines

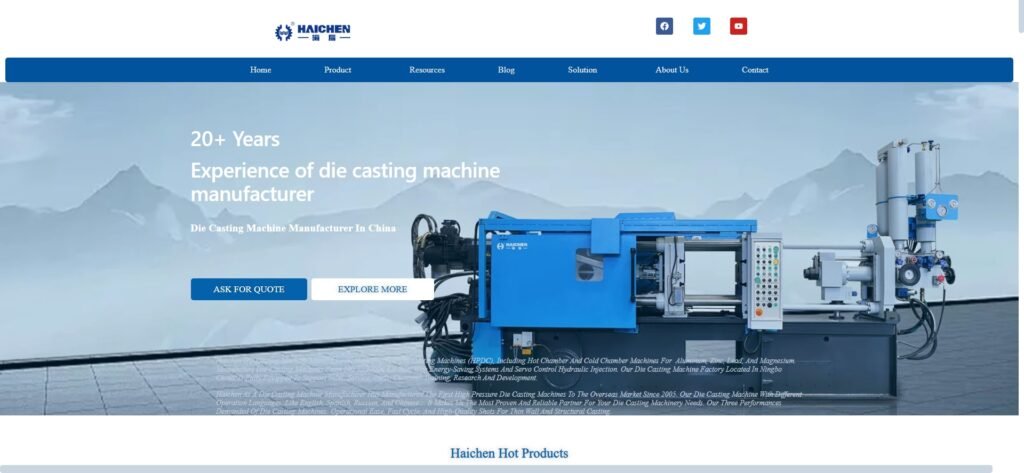

Hot chamber die casting machines

Are suitable for low melting point alloys, such as zinc, tin, and magnesium alloys, and are characterized by the fact that the chamber is connected to a furnace, from which the molten metal flows directly into the chamber.

Cold chamber die casting machines

Are suitable for alloys with high melting points, such as aluminum and copper alloys.

which are characterized by the separation of the chamber from the furnace, from which the molten metal is poured into the chamber.

Haichen can provide hot and cold chamber die casting machines from tens of tons to hundreds of tons, welcome to consult if necessary.

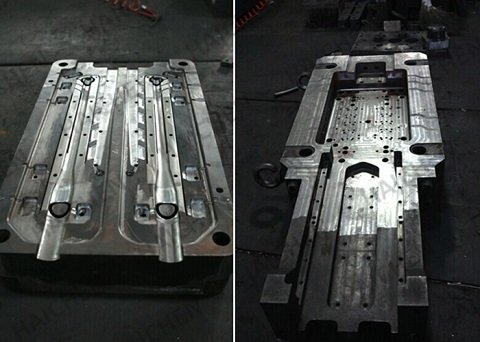

Die casting mould

Mould used in the pressure casting process, its main function is to inject molten metal into the cavity under high pressure, and cool and solidify the shape under high pressure.

Instead,the die-casting mould is usually composed of a moving mould and a fixed mould, the moving mould is fixed on the middle plate of the die-casting machine.

And the fixed mould is fixed on the fixed plate of the die-casting machine.

When the mould is closed, a cavity is formed, and the liquid metal fills the cavity under high pressure.

When the mould is opened, the moving mould is separated from the fixed mould.

And the casting is pushed out with the help of the push-out mechanism located on the moving mould.

Die casting raw materials

- Zinc

- Aluminum

- Magnesium

- Copper

- Ferroalloys

Zinc alloy

Zinc alloy has good fluidity, low melting point, and can be processed after electroplating.

And is widely used in the mobile phone industry and bathroom industry.

Aluminum alloy

Aluminum alloy has low density, high strength, excellent electrical and thermal conductivity.

And is widely used in aircraft, ships, automobiles, electronic instruments and other fields.

Magnesium alloy

Magnesium alloy has low density, high specific strength, good heat dissipation and good shock absorption.

And is suitable for mobile phones, communication equipment, auto parts and medical equipment.

Copper alloys

Copper alloys have high strength and toughness, good corrosion resistance and wear resistance,

And are commonly used in fields such as electronic communications, aerospace and shipbuilding.

Ferroalloys

Ferroalloys have high strength and hardness, and are widely used in industrial fields such as automobiles and machinery.

Haichen die casting Technology

Haichen currently has several innovative die casting technologies or methods that can effectively deal with them:

- Integrated Die Casting

- Semi-solid rheological die-casting

- Local extrusion technology

- Binder-free, mould-wall-free die casting

- Vacuum die casting

Integrated Die Casting

This technology uses a large tonnage die casting machine to highly integrate multiple individual and dispersed aluminum alloy parts.

And form die casting into 1-2 large aluminum castings at one time.

Semi-solid rheological die-casting

Compared with traditional die-casting, this process has the advantages of low forming temperature, stable filling and small solidification shrinkage.

It is able to improve the porosity defects of the casting and improve the overall quality of the casting.

Local extrusion technology

For surface and internal defects such as wrinkling, cold separation, poor filling, shrinkage porosity, and porosity of die castings.

Local extrusion technology can distinguish good products from bad products before casting processing.

Following, has advantages in the production of airtight products and thick-walled die castings.

Binder-free, mould-wall-free die casting

The new mould design allows metal powders such as iron, copper, and aluminum to die cast without the need for binders and mould wall lubricants.

This design reduces mould wear and improves the life of the mould.

Vacuum die casting

By performing die casting in a vacuum environment.

Generally,It can effectively reduce porosity and other defects in the casting, thereby improving the strength and quality of the casting.

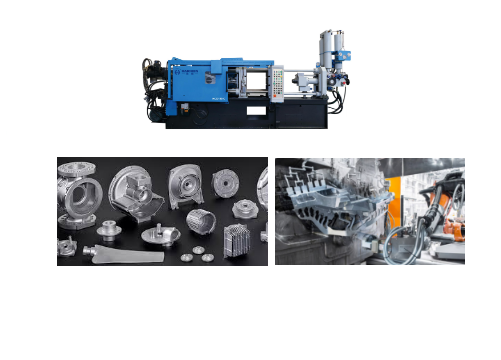

Haichen’s die casting application

Haichen’s die-casting technology is suitable for automotive engine components such as engine blocks, crankcases, and transmission housings.

In addition, aluminum alloy die-casting parts have broad application prospects in new energy vehicles, including lithium battery housings, gearbox boxes.

The development trend of die casting technology is to develop in the direction of serialization, large-scale and automation,

And at the same time, combine computer simulation technology and CAE software for simulation to optimize the die casting process.