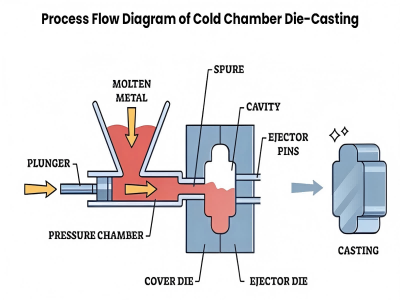

Cold Chamber Die Casting Machine is a type of equipment used for metal die casting, mainly for the production of high-precision, dimensionally consistent parts.

This machine is particularly suitable for metals with high melting points, such as aluminum, copper and brass.

Working Principle of Cold Chamber Die Casting Machine

Chamber die casting is a form of die casting. This process can produce high-quality metal parts with complex shapes and geometries.

Melting the Metal:

- Melting the metal in a separate furnace and heated to the appropriate temperature.

Pouring:

- Pour the molten metal carefully into the injection chamber using a ladle or other pouring device.

Injection of Cold Chamber Die Casting Machine:

- A hydraulic or mechanical plunger forces the molten metal into the die cavity at high pressure, ensuring that the metal fills all the details of the die.

Solidification:

- The metal cools and solidifies quickly within the die, taking the shape of the mold.

Ejection:

- Eject the solidified part from the die, ready for any post-casting treatments such as trimming or finishing.

Metals for cold chamber die casting

The cold chamber die casting process is suitable for metals with high melting points. These metals may include aluminum, magnesium, copper, etc. Therefore, it is important to understand the characteristics of a metal to use in cold chamber die casting before choosing one.

Aluminum and its alloys:

- Aluminum and its alloys are one of the most commonly used materials in cold chamber die casting because of their high melting point and good mechanical properties.

- Use aluminum alloys in automotive, aerospace and other industries because of their durability, versatility and light weight.

Copper and its alloys:

- Copper and its alloys are also important materials for cold chamber die casting, especially in applications requiring high strength and corrosion resistance.

- Use copper alloys to make components with high load capacities.

Copper:

- Copper is widely used in cold chamber die casting because of its excellent strength and corrosion resistance.

- It is often used where strength and visual appeal are required.

Magnesium and its alloys:

Although magnesium alloys have a lower melting point, they can be produced by cold chamber die casting, especially when lightweight and high strength parts are required.

Haichen cold chamber die casting machine supplier

Haichen is a cold chamber die casting supplier. Haichen’s machines can handle a wide range of metals and alloys, including those with high melting points. And it allows for the production of complex and intricate shapes with high dimensional accuracy.

Besides cold chamber die casting machines, we also supply hot chamber die casting machines and auxiliary machinery. If any demand, welcome to consult us.