Aluminum Alloys are a kind of metal alloy whose main component is aluminium.It usually contains other elements such as copper, magnesium, manganese, silicon and zinc.The addition of these alloying elements can significantly improve the properties of aluminium.It gives it higher strength, better corrosion resistance and superior machinability.

Aluminium alloys offer many advantages, such as low density, high strength, good corrosion resistance and excellent thermal and electrical conductivity.These properties have led to the use of aluminium alloys in a wide range of applications, including aviation, aerospace, automotive manufacturing, construction, electronics and electrical engineering.

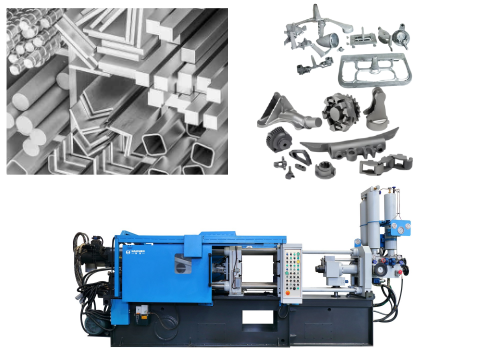

In addition, aluminium alloys have excellent formability and can be processed into a wide range of shapes and sizes through a variety of processes such as die casting, forging, extrusion and welding.

What are Aluminium Alloy die casting products?

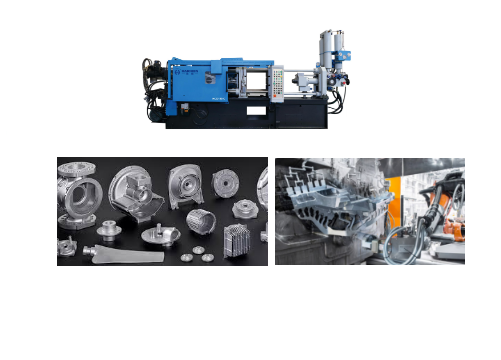

Aluminum Alloys die-casting products are widely used in many fields, especially in the automotive industry has an important position.

According to the evidence, aluminium alloy die casting products mainly include the following categories:

- Automobile structural parts

- Electronic devices

- Other industrial applications

Automobile structural parts

Aluminium alloys die castings are widely using in the manufacture of automotive structural parts, such as body structural parts and engine parts.

These products need to have high strength and good toughness to meet the demand of modern automobiles for light weight, energy saving and environmental protection.

AlSi10MgMn alloy is using in the manufacture of thin-walled, complex-shaped automotive parts due to its excellent casting properties and mechanical properties.

Electronic devices

Aluminum Alloys die casting technology is also using in the manufacture of electronic devices.

Such as 5G communication equipment in the heat sink.

These applications require aluminium alloy die castings with good thermal conductivity and structural stability.

Other industrial applications

Aluminum Alloys die castings are also used in other industrial fields, such as pump housing parts.

In addition, aluminium alloy die casting technology also plays an important role in the integrated die casting of new energy vehicles.

It helps to improve production efficiency and reduce costs.

Aluminium alloy die casting product variety, mainly concentrated in the automotive industry and other fields that need high performance materials.

With the progress of technology, the application scope of aluminium alloy die casting is still expanding.

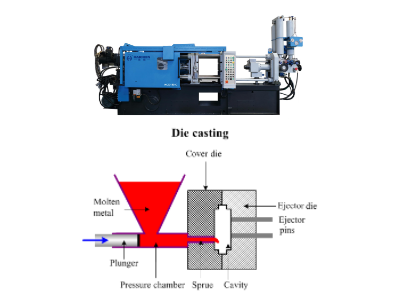

What die casting technology for aluminium alloy materials?

Die casting technologies for aluminium alloys materials mainly include High Pressure Die Casting (HPDC) and Vacuum Die Casting.

The following is a detailed description of these two technologies:

- High pressure die casting (HPDC)

- Vacuum Die Casting (Vacuum Die Casting)

- Material selection and Aluminum Alloys types

- Mould materials and process challenges

High pressure die casting (HPDC)

High pressure die casting is currently one of the most common one aluminium alloy die casting technology.

It is characterised by its ability to inject molten aluminium alloy into the mould at high speed within a short period of time and to form the mould by rapid cooling under high pressure.

This technology is capable of producing parts with smooth surfaces and high dimensional accuracy, and is suitable for mass production.

HPDC technology has high production efficiency, suitable for manufacturing small to medium-sized complex parts, such as automotive parts.

Vacuum Die Casting (Vacuum Die Casting)

Vacuum die casting is an emerging aluminium alloy die casting technology.

By vacuum in the casting process to reduce the porosity defects, improve the mechanical properties of parts.

This technology is particularly suitable for large aluminium alloy parts that require high strength and ductility.

Companies such as Tesla, for example, are investigating this technology to produce larger sized aluminium alloy parts.

Material selection and Aluminum Alloys types

Alloys commonly used for aluminium alloy die casting include AlSi9Cu3Fe and AlSiMg.

These alloys have good flow and mechanical properties.

Aluminium alloy die casting alloys usually contain elements such as silicon, copper, magnesium, iron, manganese and zinc.

These elements have a significant impact on the properties of the alloys.

Mould materials and process challenges

Die casting moulds are usually made of high temperature resistant, high strength materials .

Such as H13 tool steel, to cope with the corrosive nature of aluminium alloys at high temperatures and mould wear.

Moulds are subjecting to multiple effects of high temperature, high pressure and high speed metal flow during the die casting process.

Therefore, they must be specially designed to ensure their durability and precision.

Die casting technology for aluminium alloys is mainly achieved through high pressure die casting and vacuum die casting.

These two technologies have their own advantages and are suitable for different application scenarios and product requirements.

At the same time, the choice of mould material and optimisation of process parameters is crucial to improve product quality and production efficiency.

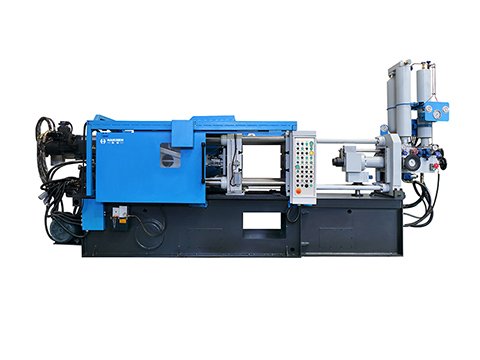

Haichen equipment for high pressure die casting of aluminium alloys

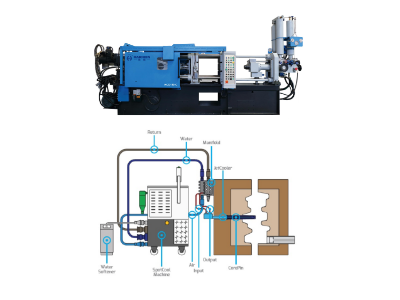

Haichen Aluminum Alloys high pressure die casting equipment mainly includes high pressure die casting machine, furnace, mould, cooling system and so on.

These equipments work together to achieve the aluminium alloy under high pressure conditions to fill the mould cavity quickly and solidify the shape.

- Haichen cold chamber high pressure die casting machine

- Haichen Aluminum Alloys furnace

- Aluminum Alloys die casting mould

- Cooling system

- Other auxiliary equipment

Haichen cold chamber high pressure die casting machine

This is the core equipment for high pressure die casting of aluminium alloy, which is using to inject the molten aluminium alloy into the mould under high pressure.

Cold chamber high pressure die casting machine usually need to withstand high pressure, generally between 400-500MPa.

To ensure that the aluminium alloy can quickly and evenly fill every corner of the mould.

Haichen Aluminum Alloys furnace

High pressure die casting of aluminium alloys requires the use of a separate furnace to melt the aluminium alloy.

The furnace, which can be manually or robotically operated, heats the aluminium alloy to a liquid state.

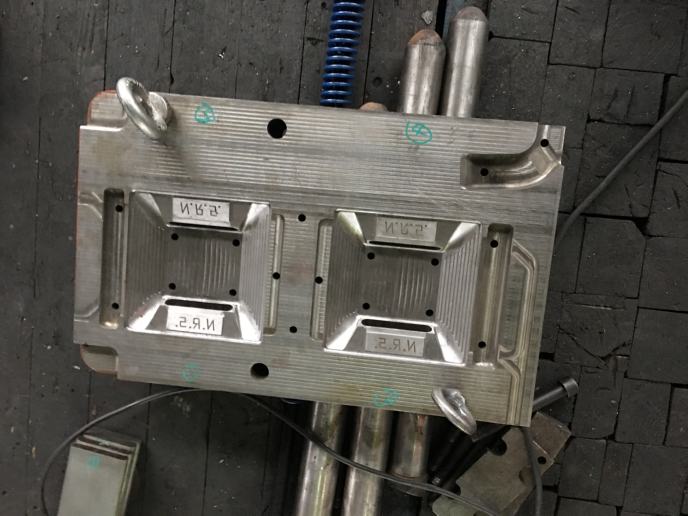

Aluminum Alloys die casting mould

The die is a key component in the high-pressure die casting of aluminium alloys, which determines the shape and size of the final product.

The mould needs to have sufficient strength and toughness to withstand the pressure during high pressure injection and to ensure the quality of the casting.

Cooling system

A cooling system is essential to ensure that the aluminium alloy solidifies quickly in the mould.

The cooling system regulates the solidification rate of the castings by controlling the temperature of the mould, thus improving productivity and product quality.

Other auxiliary equipment

Including vacuum equipment, spraying system, pick-up robot and so on.

These equipments are to improve the quality of castings, improve production efficiency and automation.

Aluminium alloy high pressure die casting equipment configuration is complex and professional, its performance directly affects the quality of the product and production efficiency.

Haichen can configure the required aluminium cold chamber die casting machine and full system of auxiliary equipment for the specific needs and production scale of your various aluminium alloy products.