Jet cooling in die casting is a process that utilizes high-pressure water to cool specific areas of the die, particularly core pins and inserts, during the solidification of the molten metal.

This technique helps to manage heat distribution, reduce porosity and shrinkage, and improve overall casting quality and die life.

Jet cooling in die casting

- High-pressure water jet

- Gas jet

High-pressure water jet

In die-casting, high-pressure water (0.3~0.8 MPa) hits the surface of the mold mandrel or mandrel through the nozzle.

And uses the convection heat transfer of water and the latent heat of phase change to quickly cool down.

And then removes the residual water droplets through pressurized air to avoid secondary oxidation.

Gas jet

In special scenarios such as thin-walled parts or when liquid residues need to be avoided, inert gas (such as nitrogen).

Or compressed air passes through the ejector to form a high-velocity air flow that directly absorbs the heat on the surface of the mold.

How does Jet Cooling work?

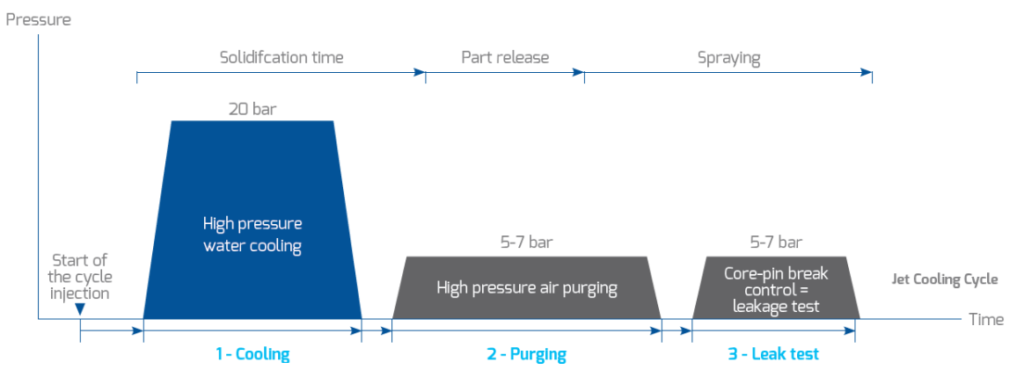

A hydraulic unit ensures the circulation of pressurized cooling water (from 3 to 20 bars) for a given period of time in the circuits of small diameter injectors (Ø from 1,2 to 2,8 mm) inserted in the specific core pins.

At the end of the cooling period, a pneumatic distributor injects air in the injector’s circuits to purges it.

In this way, the cycle can be carried out safely without the presence of water inside the circuits.

The cooling cycle is synchronized by adjustable temporizations with the die casting machine.

Technical Principles and Core Mechanisms of Jet Cooling

Hydrodynamics

Jet cooling pumps coolant such as high-pressure water or a specific cooling medium at high pressure.

Causing the fluid to impact the surface of a mold or casting at a high speed usually up to tens of meters per second.

This high-velocity impact forms an extremely thin velocity and temperature boundary layer at the lag point the center of the impact region.

Which greatly increases the local convective heat transfer coefficient.

For example, in the mandrel or mandrel area of a die-casting mold.

Jet cooling can quickly remove the latent heat released by metal solidification.

And avoid defects such as shrinkage holes and porosity caused by local overheating.

Controllability and flexibility

Cooling range and intensity can be precisely controlled by adjusting nozzle orifice diameter, arrangement (e.g., array jet) and impact angle.

For example, multi-nozzle arrays can expand the effective cooling area and alleviate the problem of temperature gradients caused by single-point jets

The core advantages of jet cooling in die casting

Mold thermal balance control

The local structure of the die-casting mold such as mandrel and slider is easy to accumulate heat.

And it is difficult for the traditional water cooling system to quickly dissipate heat.

Jet cooling is directed to these areas with high-pressure water.

Resulting in a temperature drop of up to 150°C, significantly reducing thermal fatigue and sticking and extending mold life.

Defect Suppression and Quality Improvement

In the production of complex, thin-walled castings.

Such as automotive crankcases and notebook housings, jet cooling optimizes the solidification path of the molten metal.

For example, by rapidly cooling thick-walled areas, shrinkage stresses are reduced.

Porosity and shrinkage defects are avoided, and the surface quality is improved by more than 30%.

Reduced cycle time

Jet cooling can reduce mold cooling time to 10-15 seconds compared to more than 30 seconds for traditional methods, increasing productivity.

For example, in one crankcase case, jet cooling reduced the cycle time per part by 25 percent and increased production capacity to several thousand pieces per day.

Energy efficiency optimization

Compared to traditional cooling methods, jet cooling reduces overall energy consumption through precise heat dissipation.

The energy consumption of the high-pressure water pump is only 60%-70% of that of the circulating water cooling system, while avoiding the use of excessive cooling media.

Technical Challenges and Solutions for Jet Cooling

- Temperature gradient problem

- System reliability risk

- Media Selection Limitations

Temperature gradient problem

The cooling range of a single nozzle is limited, which can easily lead to uneven surface temperatures.

Solutions include the use of multi-nozzle arrays, optimized nozzle spacing.

And enhanced turbulence in combination with spoiler columns.

System reliability risk

High-pressure water contact with molten metal can cause an explosion (e.g., when the mandrel breaks).

Pressure sensors and real-time monitoring systems need to be integrated to ensure that the coolant supply is automatically cut off in case of anomalies.

Media Selection Limitations

Jet coolants need to be insulating, low corrosive (e.g., fluorinated fluids, silicone oils).

And there are few types of fluids to choose from.

The focus of research has shifted to nanofluids (e.g., cuprous oxide-water mixtures) to improve heat transfer performance.

Jet cooling in die casting future development direction

Intelligent control

Combined with AI algorithms, real-time analysis of the mold temperature field.

Dynamic adjustment of jet parameters (such as pressure, flow), to achieve adaptive cooling.

Composite cooling technology

Jet cooling is combined with micro-channel cooling, such as using jets to supply liquid to micro-channels.

Which not only reduces the pressure drop but also expands the heat dissipation area.

Which is suitable for ultra-large die castings (such as integrated body structures).

Material and process innovation

Develop high-temperature, corrosion-resistant nozzle materials (e.g., silicon carbide ceramics) and optimize the microstructure of jet impact surfaces (e.g., bionic fins) to further improve heat transfer efficiency.