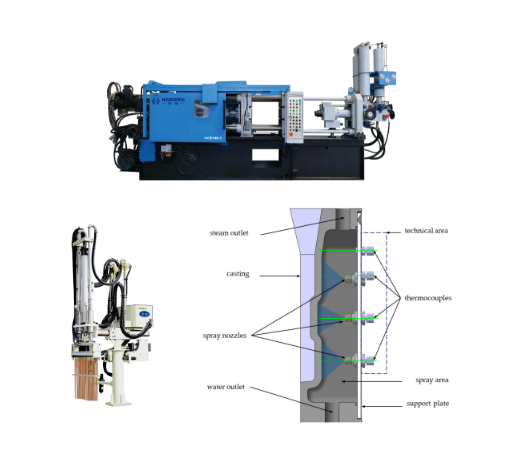

Die casting machine sprayer definition is a device to spray the mold release agent on mould inner cavity during die casting process.

Die casting machine sprayer function is by spraying the mold release agent to reduce the adhesion between the casting and the mold. To improve the demoulding efficiency and quality of the casting. And also improve the surface finish of the casting and reduce defects such as internal pores.

The working principle of die casting machine sprayer includes the following parts:

- Die casting machine sprayer technical features

- Spraying application technology

- Die casitng machine sprayer control and optimization

- Application scenarios

- Innovative design

Die casting machine sprayer technical features

- Nozzle design

- Automatic control

- Cooling and lubrication

The die casting machine sprayer manipulator is the core part of the spraying system. It realizes uniform spraying of the inner cavity of the mold through process actions. Such as mechanical arm extension, blowing, spraying, and blowing.

These manipulators can be connecting rod type or upright type. With the characteristics of structural optimization, high degree of automation, and high spraying efficiency.

Nozzle design

Sprayers usually equip with high-pressure nozzles (such as electric or pneumatic types) to atomize the liquid into fine droplets through compressed air or mechanical pumps to achieve uniform coverage of the mold surface.

Automatic control

Modern sprayers integrate timers, counters and mixing valves to accurately control spraying time, frequency and liquid ratio. For example, continuous spray systems spray continuously in each cycle, while intermittent spraying is suitable for small batch production.

Cooling and lubrication

Some sprayers combine cooling functions to reduce mold temperature by spraying coolants (such as water or special coolants), especially suitable for large aluminum molds.

Spraying application technology

- Automation and precision

- Components and controls

- Cooling and lubrication

Die casting machine spraying technology includes pulse spraying and continuous spraying. Among it pulse spraying technology can effectively control the temperature gradient on the mold surface, reduce the generation of thermal stress, and increase the life of the mold. At the same time, it reduces the use of release agent and improves the surface quality of the casting.

Automation and precision

Modern sprayers usually integrate automation systems (such as servo motors and linkages) to adapt to the spraying needs of different molds.

For example, a device that automatically adjusts the position of the spray gun through a linkage ensures that the spray gun is always between the molds to avoid obstructing the operation

Components and controls

Sprayers usually contain components such as pumps, mixing valves, and nozzles. It is mentioned that the sprayer adjusts the ratio of water and additives through a mixing valve and accurately controls the liquid flow through a pump to adapt to different production needs.

Cooling and lubrication

Sprayers are not only used to spray release agents, but also have cooling and lubrication functions. Spray cooling quickly removes mold heat through fine mist and is suitable for cooling large aluminum parts.

There is also an application based on in-mold spraying technology. This technology uses the spray pipe and atomizer designed inside the mold to achieve synchronous action with the spray manipulator on the die-casting machine, which greatly reduces the scrap rate of castings.

Die casitng machine sprayer control and optimization

- Multi-nozzle independent control

- Modular design

- Matching temperature and lubrication requirements

- Cooperative optimization of production processes

Control and optimization of spraying rocess is the key to improving spraying efficiency and quality. By adopting advanced control systems, such as hydraulic servo control systems, precise control of spraying manipulators can be achieved, thereby improving the response performance and stability of the system.

Multi-nozzle independent control

By increasing the number of nozzle rows, water and release agent can be sprayed independently, and the cooling effect can be optimized through computer control, while reducing the consumption of release agent and water. Further explanation: the spray time of the fixed mold and the movable mold can be adjusted separately to improve the spray flexibility.

Modular design

The automatic sprayer adopts a modular structure (mechanical, circuit, and air circuit), and replaces the traditional slide rail with a ball guide rail to reduce maintenance costs and improve accuracy. The spray head design allows vertical movement to adapt to complex mold structures.

Matching temperature and lubrication requirements

Dynamically adjust the spray time and intensity according to the mold temperature and lubrication requirements. For example, the spray time needs to be extended in high-temperature areas to prevent sticking. The drying mechanism can be optimized by adjusting the nozzle airflow rate to reduce particle clogging problems.

Cooperative optimization of production processes

The system improves production line efficiency and material utilization by optimizing the collaborative work of the conveyor belt and spray equipment. The joint spray solution reduces cross-interference and optimizes coverage through the collaborative work of drones and ground equipment.

In addition, by optimizing spraying process parameters, such as spraying pressure, blowing pressure, atomization pressure, etc., the stability of casting surface quality can be further improved.

Haichen die casting machine sprayers are engineered to optimize the mold release and cooling process. They offering significant advantages in efficiency and part quality.

Haichen produce sprayers with precise and multi-nozzle design. They ensure uniform coverage of release agent across the mold surface, preventing sticking and ensuring clean part ejection. Help to reduce lubricant waste and cycle time. This precision directly contributes to extended mold life, superior surface finish on castings, and consistent, high-volume production efficiency.

Application scenarios

- Continuous and intermittent spray

- Environmental protection and sustainability

Continuous and intermittent spray

Depending on production requirements, the sprayer can use continuous spray or intermittent spray. Continuous spray is suitable for large-scale production, while intermittent spray is more flexible and suitable for small batches or complex molds.

Environmental protection and sustainability

The new spray system reduces energy consumption and waste disposal costs by reducing the use of water and compressed air, while improving environmental performance. Electrostatic spray technology can reduce the amount of lubricant used by 99.9%, significantly extending the life of the mold.

Innovative design

In order to improve the efficiency and quality of spraying, the design of spraying device is constantly innovating.

- The new vertical axis spraying device developed by some companies use belt drive instead of traditional rack and pinion drive to improve the performance limit of the device.

- Moreover, there are semi-automatic die-casting equipment based on sprayer/mold integration, which aims to reduce production cycle and spray agent consumption and improve product quality.

Above all, we can know that die casting machine sprayer definition related technologies realize effective spraying of the inner cavity of the mold in a variety of ways, which not only improves the demoulding efficiency and quality of the casting, but also improves the surface finish of the casting and reduces defects such as internal pores.

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

When you have any demand, feel free to contact us.