The Effects of High-Pressure Die Casting (HPDC): Advantages, Limitations, and Applications

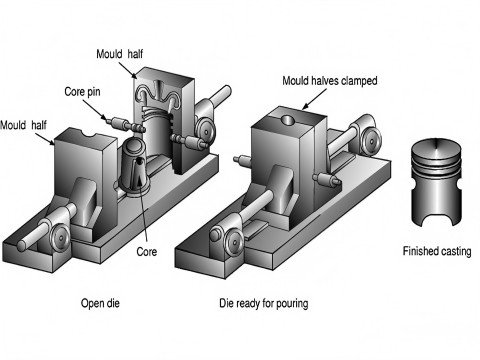

High-pressure die casting (HPDC) is a manufacturing process where molten metal is injected into a steel mold (die) under extreme pressure (typically 10–200 MPa). This method is widely used for producing complex, high-volume metal parts with tight tolerances. Below are the key effects of HPDC, categorized into advantages, limitations, and material/design considerations:

1. Advantages of High-Pressure Die Casting

- High Production Efficiency

- Rapid Cycle Times: Parts solidify quickly due to high pressure and fast cooling, enabling mass production (e.g., thousands of parts per day).

- Automation-Friendly: Compatible with robotic systems for mold handling and part ejection.

- Exceptional Precision and Surface Finish

- Thin-Wall Capability: Produces walls as thin as 0.5 mm with intricate geometries (e.g., automotive grilles, electronics housings).

- Smooth Surfaces: Minimizes post-processing (e.g., machining, polishing).

- Superior Mechanical Properties

- Fine Grain Structure: High pressure refines the metal’s microstructure, enhancing strength and hardness.

- Low Porosity: Reduced gas entrapment compared to gravity casting (with proper venting and vacuum systems).

- Material Efficiency

- Minimal Waste: Excess material (e.g., sprues, runners) is recycled, achieving near-net-shape production.

- Cost-Effective for High Volumes

- Low per-part cost due to high throughput and reduced labor.

2. Limitations and Challenges

- Porosity and Internal Defects

- Air Entrapment: High-speed injection can trap air, leading to micro-voids that weaken mechanical properties.

- Mitigation: Vacuum-assisted HPDC or secondary processes like hot isostatic pressing (HIP).

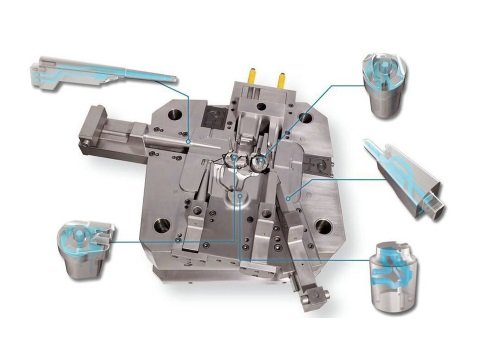

- Tooling Costs and Complexity

- High Initial Investment: Dies made from hardened steel (e.g., H13) are expensive but durable (100,000+ cycles).

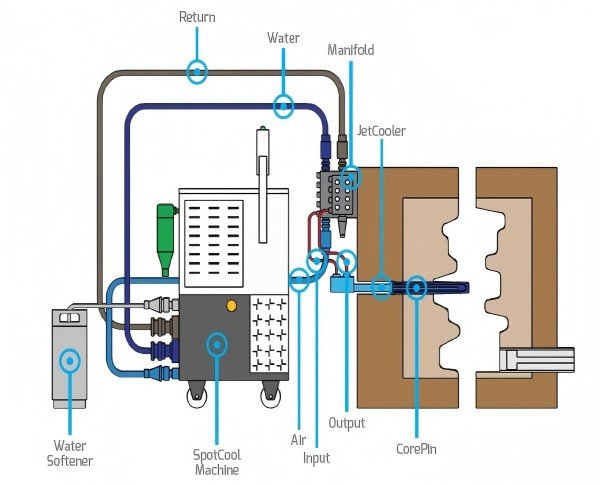

- Design Constraints: Complex molds require precise cooling channels and venting systems.

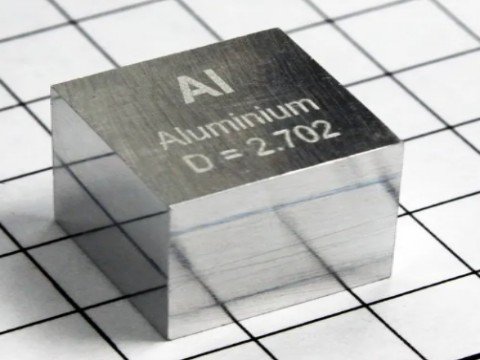

- Limited Material Options

- Primarily used for non-ferrous alloys (e.g., aluminum, zinc, magnesium).

- Not suitable for high-melting-point metals (e.g., steel, titanium).

- Thermal Stress and Die Wear

- Thermal Fatigue: Repeated heating/cooling cycles degrade dies over time.

- Soldering: Molten metal adhesion to the die surface, requiring frequent maintenance.

3. Material-Specific Effects

- Aluminum Alloys (e.g., A380, A383):

- High fluidity enables thin walls but may suffer from hot tearing.

- Post-casting heat treatment (e.g., T5, T6) improves strength but increases cost.

- Zinc Alloys (e.g., Zamak):

- Excellent dimensional stability and surface finish but lower strength.

- Magnesium Alloys (e.g., AZ91D):

- Ultra-lightweight but prone to oxidation during melting.

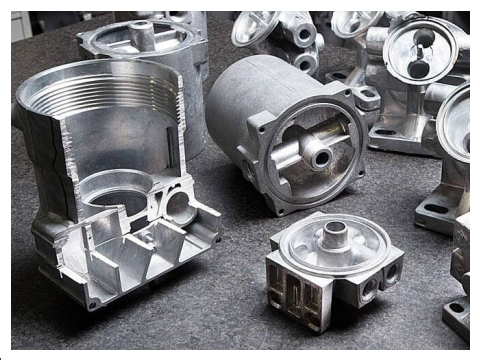

4. Industry Applications

- Automotive: Engine blocks, transmission housings, and structural brackets (e.g., Tesla’s gigacastings).

- Electronics: Heat sinks, smartphone frames, and connector housings.

- Consumer Goods: Appliance components, power tools, and decorative hardware.

5. Comparison with Other Casting Methods

| Factor | HPDC | Low-Pressure Die Casting | Sand Casting |

|---|---|---|---|

| Production Speed | Very High (seconds/part) | Moderate | Slow |

| Surface Finish | Smooth (Ra 1–2 µm) | Good | Rough (Ra 12–25 µm) |

| Part Complexity | High (thin walls, details) | Moderate | Low |

| Cost Efficiency | High for large volumes | Medium | Low for prototypes |

Why is high pressure used in die casting?

The main reasons for using high pressure in high-pressure die casting (HPDC) can be summarized as follows:

1. Filling complex mold structures

High pressure (usually in the range of 100 to 3000 tons) forces the molten metal to quickly enter every tiny corner of the mold, especially complex or thin-walled cavities.

This high pressure can overcome the resistance to metal flow and ensure that the melt completely fills the mold, thereby producing parts with complex geometry and precise dimensions.

2. Improve production efficiency and surface quality

High pressure combined with high injection speed (up to more than 100 inches per second) allows the metal to be filled quickly before solidification, significantly shortening the molding cycle.

At the same time, high pressure reduces oxidation and turbulence when the metal contacts the mold, helps to form a smooth surface and reduces the need for post-processing.

3. Reduce porosity and improve mechanical properties

Although high-pressure injection may introduce turbulence (causing gas entrainment), high pressure itself compresses the gas in the melt and reduces porosity through rapid solidification and subsequent pressure holding stages.

For example, studies have shown that increasing pressure can reduce the size of pores and make them more evenly distributed.

In addition, high pressure promotes metal grain refinement, improving the density, hardness and tensile strength of parts.

4. Support thin-wall structure production

High pressure allows the manufacture of extremely thin wall thicknesses (aluminum parts can be as thin as less than 2 mm, zinc parts up to 1 mm).

This capability is critical to lightweight design and is widely used in the automotive and aerospace fields.

5. Ensure dimensional accuracy and consistency

The mold is made of high-precision steel (such as H13 tool steel), combined with the rapid solidification of metal under high pressure, so that the parts have strict tolerances (up to micron level) and minimal batch-to-batch differences.

6. Optimize cooling uniformity

High pressure promotes uniform distribution of the melt in the mold, and combined with rapid solidification to reduce shrinkage deformation during cooling, avoid gas stagnation and local thermal stress, thereby improving the overall structural integrity.

Potential contradictions and balances:

Although high pressure may cause pores due to turbulence, this problem can be effectively alleviated through vacuum-assisted technology (such as vacuum die casting) and process optimization (such as adjusting the injection speed and pressure curve).

In addition, the rapid solidification and compression effects brought about by high pressure themselves offset some of the negative effects.

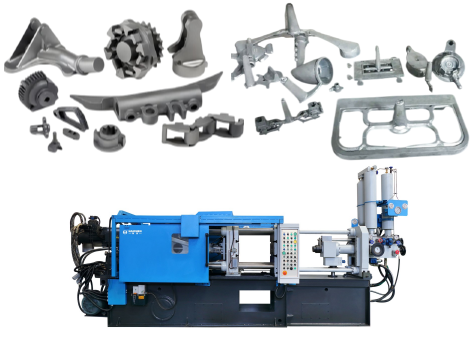

Haichen die casting machine company

Haichen is a Chinese manufacturer specializing in the R&D, production and sales of die-casting machines. It was founded in 2005 and is headquartered in Ningbo, Zhejiang.

The following is a detailed analysis of Haichen’s die-casting machine products:

1. Product Type and Technical Features

Cold Chamber Die Casting Machine:

Suitable for high-melting-point alloys such as aluminum, magnesium, and copper (melting temperature exceeds 700°C).

The cold chamber design separates the furnace from the machine to avoid damage to the hydraulic system caused by high temperature. Its tonnage range is wide, from 500 kN (about 50 tons) to 30,000 kN (about 3000 tons), and is equipped with a servo energy-saving system and a real-time control system.

For example, the HCD-C series adopts four-stage injection control (slow speed, first fast speed, second fast speed, and boost), combined with magnetic scale positioning, to improve injection accuracy and efficiency, especially suitable for the production of thin-walled and complex structural parts.

Typical applications include automotive parts (such as radiators, structural parts), LED lamp housings, kitchen utensils, etc.

Hot chamber die casting machine:

Designed for low melting point alloys such as zinc and lead, with a tonnage range of 30 tons to 280 tons.

Its characteristic is that the injection mechanism is immersed in the molten metal (gooseneck design) to achieve fast cycle production, suitable for small precision parts such as lock cylinders, door handles, pipe fittings, etc.

For example, the HCH series optimizes energy consumption through the servo system and supports automated production.

2. Core technology advantages

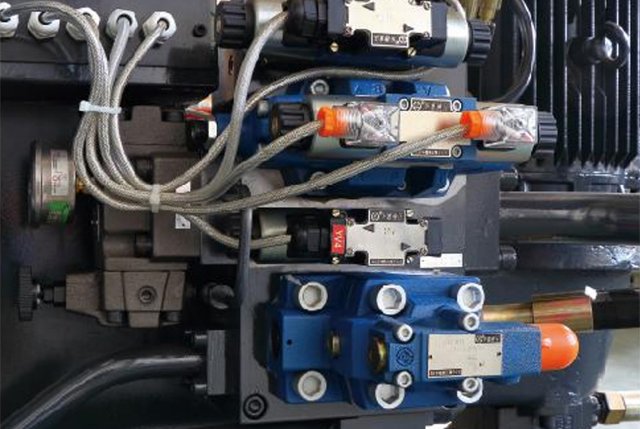

Control system:

Adopts Siemens PLC and multi-language interface (supports Chinese, English, Spanish, etc.), which is convenient for global customers to operate.

Hydraulic system:

Core components come from well-known European, American and Japanese brands (such as Bosch Rexroth) to ensure high-speed and stable operation.

Energy-saving design:

Servo drive technology can reduce energy consumption by 30%-50%, in line with environmental protection trends.

High-precision mold adaptation:

Optimize key components through CAD/CAE design and finite element analysis, support large template size and long mold opening stroke, and compatible with complex molds.

3. Market and certification

Global layout: Products are exported to more than 30 countries or regions, with key markets including India, Russia, Mexico and China, especially in the field of automotive integrated die-casting.

Certification standards: Passed ISO 9001 and CE certification, in line with Chinese national standards (such as GB/T 21269-2023) and EU safety standards.

4. After-sales service and support

Comprehensive solution:

Provide one-stop service from die-casting machines, molds to automated auxiliary equipment (such as pickup robots, sprayers).

Warranty policy: The warranty period starts from the date of shipment, and customers are required to operate and maintain according to specifications. Spare parts are purchased globally for easy local replacement.

Technology research and development: Continuously invest in new technologies such as vacuum casting and extrusion casting to promote the intelligent upgrading of equipment.

Haichen die-casting machines are technologically advanced, highly adaptable and global services as their core competitiveness, covering diverse needs from small zinc alloy parts to large aluminum structural parts.

Its model of continuous innovation and collaborative development with customers has enabled it to occupy an important position in the die-casting industry.

Contact us and we will give you a powerful boost in the production of your die-cast metal products.

Conclusion

High-pressure die casting excels in producing lightweight, complex parts with high dimensional accuracy and efficiency. However, its limitations—such as porosity risks, high tooling costs, and material restrictions—require careful process optimization. Advances like vacuum-assisted HPDC and simulation software (e.g., MAGMA, FLOW-3D) are addressing these challenges, expanding its use in industries demanding precision and scalability. For projects requiring ultra-high strength or exotic materials, alternative methods like investment casting or forging may be more suitable.