The pressure accumulator in die casting is a device that stores hydraulic pressure and releases it quickly to maintain consistent injection pressure, ensuring precise and uniform filling of the mold cavity during the casting process.

The pressure accumulator is a very important component in a die casting machine.

It does two main things: store the pressure of the hydraulic oil and then release it quickly when needed. This ensures that the pressure during the injection process (that is, the process of forcing the molten metal into the mold) is stable and reliable.

Especially in those die casting operations that require fast and high pressure, this stable pressure is critical to making high-quality and consistent die castings.

Next, let’s talk about what the pressure accumulator is and why it is so important in the die casting process.

Definition of Pressure Accumulator

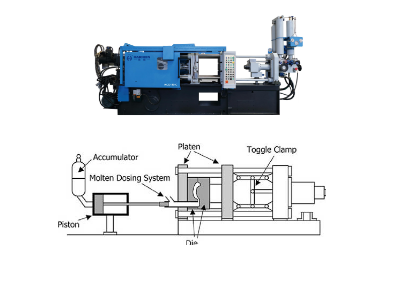

A pressure accumulator is used in hydraulic machines to store and release pressure. It is similar to a hydraulic machine’s reservoir in that it keeps a steady pressure supply, which ensures flawless operation of the machine. The accumulator is made of a pressure vessel, a piston, and hydraulic liquid.

Function of Pressure Accumulator

- Maintaining Consistent Pressure

- Reducing Pressure Fluctuations

- Improving Machine Efficiency

Maintaining Consistent Pressure

One of the most important functions of a pressure accumulator is to maintain consistent hydraulic pressure. The machine during the die casting operation needs a constant flow of hydraulic liquid to power its injection unit and other hydraulic parts. The accumulator helps maintain pressure at all times, even in times of heavy usage.

Reducing Pressure Fluctuations

Fluctuation of pressure leads to defects in the final casting such as incomplete filling or gaps on the surface of the casting. The pressure accumulator helps to even out these pressure changes. This helps ensure that the injected molten metal is done at a constant flow and at the correct points in the mold.

Improving Machine Efficiency

Efficiency of a die casting machine is enhanced with using a Pressure accumulator. Known increase of efficiency comes from having steady supply of pressured liquid, which reduces the number of adjustments made, down time of the machine, increases rate of production, and quality of the castings.

HAICHEN’s Technical Practice with Pressure Accumulator Systems

The pressure accumulator systems in HAICHEN die casting machines are specially designed and optimized. They meet the strict needs of modern die casting for fast response and very stable pressure.

- Selecting and Matching High-Performance Accumulators

- System Integration and Precise Control

- Case Study: Ensuring Stability for Large Part Production

Selecting and Matching High-Performance Accumulators

HAICHEN chooses fast-response diaphragm or piston accumulators based on machine size and process needs. We carefully calculate and set the right pre-charged nitrogen pressure. This makes sure the accumulator stores and releases energy with maximum efficiency. It gives millisecond-level power support for the high-pressure intensification stage at the end of injection.

System Integration and Precise Control

The accumulator does not work alone. HAICHEN integrates it into a smart hydraulic control system. It works with fast servo valves and pressure sensors. During injection, the system watches the pressure in real time. It tells the accumulator to instantly add oil pressure at the exact right moment. This smooths out pressure changes and helps the actual injection curve follow the set process perfectly.

Case Study: Ensuring Stability for Large Part Production

A customer making new energy vehicle body structures needed extreme performance for filling huge molds fast and under high pressure.

- Challenge: The part was very large. The injection system had to deliver huge, stable hydraulic power in a very short time. Traditional systems risked pressure drop at the end, causing inconsistent internal quality.

- HAICHEN Solution: Our 880-ton machine used a cluster of large-capacity pressure accumulators. They connected in parallel to the injection circuit. A special control module managed them in sequence. They could release and refill energy in stages based on the needs of each injection phase.

- Result: This solved the pressure stability problem with huge oil flow. The pressure stability at the final injection stage improved by over 70%. This ensured the metal was packed tightly even in the enormous cavity.

Process Flow

- Charging Phase: Hydraulic oil enters the accumulator, compressing nitrogen gas.

- Standby Phase: Energy is stored at high pressure (typically 80% of system pressure).

- Discharge Phase: Valves open during injection, allowing gas expansion to force oil into the injection cylinder.

- Structural Design: Types and Components

Common Types in Die Casting Machines

| Type | Structure | Application Scope |

| Piston Accumulator | Metal piston separates gas/oil chambers | High-pressure systems (>250 bar) |

| Bladder Accumulator | Rubber bladder isolates nitrogen | Compact systems, faster response |

| Diaphragm Accumulator | Metal diaphragm for separation | Aerospace-grade precision |

Components of Pressure Accumulator

- Pressure vessel

- Piston or bladder

- Hydraulic oil

Pressure vessel

This is the main structure of the accumulator, and its main task is to safely contain the high-pressure hydraulic oil. In order to ensure durability and long-term reliability, it is usually made of very strong materials, such as steel or aluminum alloy.

Piston or bladder

This is a key moving part installed inside the pressure vessel. Its core function is to separate the hydraulic oil from the gas (usually nitrogen) or air in the container. It is through its movement that the accumulator can store pressure and release it in time when the system needs it.

Hydraulic oil

Hydraulic oil is the “blood” of pressure transmission. It flows inside the accumulator and is responsible for effectively transmitting pressure. When choosing hydraulic oil, the most important points are two: first, it must be compatible with the other components of your entire hydraulic system (it cannot damage seals or corrode pipelines); second, it must be “tough” enough to withstand the extremely high pressure environment generated by the die casting process.

The pressure accumulator is not merely an accessory but the beating heart of die casting machines. By mastering energy storage and release, it enables the high-speed, high-pressure processes required for complex, defect-free castings—from automotive parts to 5G heat sinks.

As die casting evolves toward larger, more precise, and sustainable production (e.g., mega-castings for EVs), accumulators will continue to drive innovation through smarter energy management and IoT integration.

For HAICHEN and industry peers, optimizing accumulator design—balancing gas dynamics, thermal stability, and safety—remains key to leading the next wave of die casting excellence.

Understanding the role of the pressure accumulator in die casting is essential for maintaining high – quality and efficient production. By maintaining consistent pressure, reducing fluctuations, and improving machine efficiency, the pressure accumulator contributes to the overall success of the die casting process.