Gooseneck die casting, also known as hot-chamber die casting, is an efficient metal casting process ideal for low-melting-point alloys (e.g., zinc, magnesium, lead).

The gooseneck tube is a critical component in die-casting machines, connecting the molten metal furnace to the die-casting mould. Over time, wear and tear diminishes its efficiency.

The operating principle of a hot-chamber die casting machine involves feeding molten metal into the mould from a reservoir. At the start of each cycle, the machine’s piston retracts, causing the molten metal to rapidly fill the gooseneck. This is why it is termed a gooseneck die casting machine.

Its key feature is the gooseneck-shaped metal delivery system.

The process involves the following steps:

Basic steps of hot chamber die casting

- Mold Preparation

- Gooseneck Filling with Molten Metal

- High-Pressure Injection

- Pressure Holding and Solidification

- Mold Opening and Ejection

- Plunger Reset and Cycle Repeat

Mold Preparation

- Clean and lubricate the two-part mold (fixed and ejector halves) to ensure smooth operation. The mold, typically made of heat-resistant steel, is designed with cavities to shape the final part. Multi-cavity molds may be used for high-volume production.

Gooseneck Filling with Molten Metal

- The gooseneck (a curved metal tube) is submerged in a furnace containing molten metal.

- Initially, the plunger (a piston) is in its raised position, allowing molten metal to flow into the gooseneck via gravity or inlet ports.

- The gooseneck and nozzle are heated (400–500°C) to maintain metal fluidity and prevent solidification.

High-Pressure Injection

- A hydraulic system drives the plunger downward, forcing molten metal through the nozzle into the mold cavity at high pressure (10–70 MPa).

- Injection occurs rapidly (1–1.5 seconds) to minimize oxidation and defects.

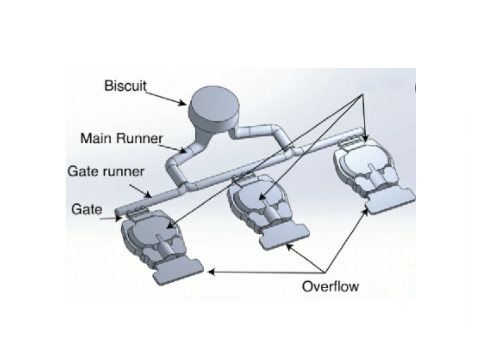

- Metal flow path: Furnace → Gooseneck → Nozzle → Sprue → Mold cavity.

Pressure Holding and Solidification

- The plunger maintains pressure until the metal solidifies completely (seconds to tens of seconds). This step ensures dense casting with minimal shrinkage (e.g., zinc alloys solidify in ~8 seconds).

- Cooling time depends on part thickness and alloy properties.

Mold Opening and Ejection

- The mold opens, and ejector pins on the ejector half push the solidified casting out.

- If cores are used (for internal features), they retract before ejection.

Plunger Reset and Cycle Repeat

- The plunger retracts to its upper position, allowing any unused molten metal to flow back into the gooseneck.

- The furnace continuously replenishes molten metal for the next cycle.

- Cycle times are short (e.g., ~10 seconds for zinc alloys, ~15 cycles/minute for magnesium).

Key Features and Limitations

- Materials: Limited to low-melting-point alloys (zinc, magnesium, lead). High-melting-point metals (e.g., aluminum) corrode the gooseneck over time.

- Advantages: High automation, fast cycles, and minimal metal waste due to integrated furnace-gooseneck design.

- Applications: Ideal for small, complex parts with smooth surfaces (e.g., automotive components, electronics housings).

This process enables mass production of precision parts with tight tolerances and excellent surface finishes, making it a cornerstone of modern metal casting.

What is gooseneck in die casting?

The gooseneck is a critical component in hot-chamber die casting (also called gooseneck die casting), a process optimized for low-melting-point alloys like zinc, magnesium, lead, and some copper alloys. Below is a detailed breakdown of its structure, function, and role in the die casting workflow:

- Definition and Structure

- Functional Role in the Casting Process

- Advantages of the Gooseneck System

- Limitations and Material Constraints

- Comparison to Cold-Chamber Systems

Definition and Structure

The gooseneck is a curved metal tube that acts as the primary conduit for molten metal transfer between the furnace and the mold cavity. Key structural features include:

- Design: Resembling the shape of a goose’s neck, it connects the injection mechanism (plunger/piston) to the mold sprue .

- Material: Made from high-quality cast or forged steel to withstand prolonged exposure to molten metal (400–500°C) and resist thermal degradation .

- Components:

- Nozzle: The outlet end that interfaces with the mold’s sprue hole to direct molten metal into the cavity .

- Cylindrical lining: Houses the plunger and ensures precise metal flow during injection .

- Replaceable parts: Designed for easy replacement due to gradual wear from high-temperature and high-pressure cycles .

Functional Role in the Casting Process

The gooseneck is central to the hot-chamber die casting cycle, which involves:

Molten Metal Intake

- The gooseneck is submerged in the furnace’s molten metal bath. When the plunger retracts, metal flows into the gooseneck via gravity or inlet ports .

- Continuous heating ensures the metal remains fluid, preventing premature solidification .

High-Pressure Injection

- A hydraulically or pneumatically driven plunger forces molten metal through the gooseneck and nozzle into the mold cavity at pressures ranging from 10–70 MPa (1,450–10,000 psi) .

- The curved design minimizes turbulence and oxidation during rapid filling (1–1.5 seconds) .

Pressure Holding and Reset

- After injection, the plunger maintains pressure until the metal solidifies, ensuring dimensional accuracy and reducing porosity .

- Post-solidification, the plunger retracts, allowing residual metal to flow back into the gooseneck for reuse in the next cycle .

Advantages of the Gooseneck System

- Efficiency: Integrated with the furnace, it eliminates the need for external metal transfer, enabling fast cycle times (e.g., 15 cycles/minute for magnesium) .

- Precision: Ensures consistent metal flow and minimizes waste, critical for high-volume production of complex, thin-walled parts like automotive components and electronics housings .

- Automation: Streamlines the casting process by combining melting, injection, and recycling in a single machine .

Limitations and Material Constraints

- Material Compatibility: Suitable only for low-melting-point alloys (e.g., zinc, lead). High-melting-point metals like aluminum corrode the gooseneck over time .

- Wear and Maintenance: Prolonged exposure to molten metal and high-pressure cycles degrades the gooseneck, necessitating periodic replacement .

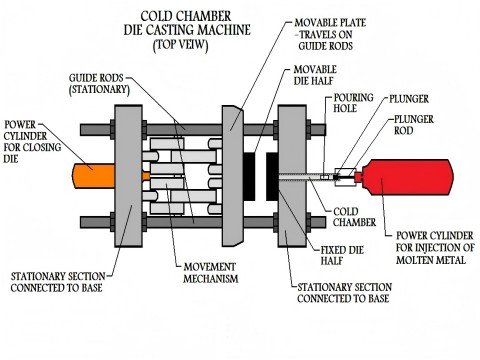

Comparison to Cold-Chamber Systems

Unlike cold-chamber die casting (used for aluminum), the gooseneck system avoids separate metal ladling, reducing cycle time and energy consumption. However, it sacrifices versatility in material selection .

The gooseneck forms the very heart of hot-chamber die casting and ensures fast, accurate production of parts with fine surfaces plus good mechanical properties. Therefore, it is designed with more emphasis on thermal strength and performance characteristics for any industry that requires large quantities of complex metal parts. However, its use is limited by material constraints and also high maintenance, thus emphasizing process and alloy selection.

Contact Haichen at any time to learn more!

Haichen: Leading Manufacturer of Die-Casting Machines

At Haichen, we understand the critical importance of selecting the appropriate gooseneck for your die-casting operations. Our advanced die-casting machine designs accommodate various gooseneck types, ensuring optimal performance and flexibility. Whether you require simple straight goosenecks for basic applications or precision goosenecks for high-accuracy casting, Haichen delivers tailored solutions to meet your requirements.

We are committed to innovation and quality, ensuring our machines incorporate the latest technology to enhance production efficiency, minimise downtime, and elevate overall casting quality. By choosing Haichen, you select a partner dedicated to helping you achieve excellence in your die-casting processes.