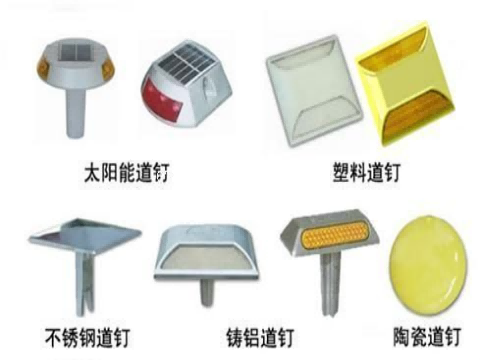

Materials for making road studs include aluminum, stainless steel, polycarbonate, and rubber.

Road studs, or reflective road markers, are an important part of road safety as they improve visibility for the drivers and provide guidance, particularly during night driving.

While these markers may seem small in size, they are very important and have a big effect. They are made from a variety of materials which have different properties suitable for different uses.

Durability, visibility, and longevity are all factors of a road stud’s material as they are crucial to the road stud’s visibility.

This post aims to explain road studs, the benefits of aluminum as the material to manufacture them, and other road stud materials.

Materials in road studs

Roads studs can be manufactured from various materials. Each material has its unique properties which allow it to be more suited to a particular condition. The following are materials that are used to make road studs.

- Aluminium:Because of its lightweight and durability, aluminum is widely used in streetlamps because of its low maintenance properties. In addition, aluminum is corrosion resistant and has good strength under impact.

- Stainless steel:It is specifically chosen for its remarkable durability, strength, and corrosion resistance which poses no limitation in the most demanding applications.

- Polycarbonate:This plastic is used mainly because of its clarit and ability to withstand tremendous impact. It is also used to enhance visibility by reflection.

- Rubber:This flexible and durable material is used for movable, portable and temporary traffic control setups.

Situations concerning the use of road markers

- Assisting vehicle navigation: for the identification of road peripheries and boundaries of interection and bends.

- Increasing safety during night driving: ensures adequate safety while driving at night, using reflective materials.

- Other applications: for example glass markers and solar markers.

Benefits of Using Aluminum in Road Studs

In comparison to other metals, aluminum certainly stands out for the following reasons:

- Cost Effectiveness: The reduced weight of aluminum not only facilitates lower shipping costs, but also minimizes installation expenses.

- Durability: Road studs manufactured with aluminum will withstand the elements for a prolonged duration.

- Maintenance Free: Aluminum, which will not break under fixed energy impacts, will fracture freely. Cars will not damage aluminum road studs, making them maintenance-free.

- Environmentalism: The processes to refine aluminum alloys into the required shapes for road studs considerably reduces expenses.

- Polishing: Aluminum road studs can take a wide variety of textures and colors, making them more appealing.

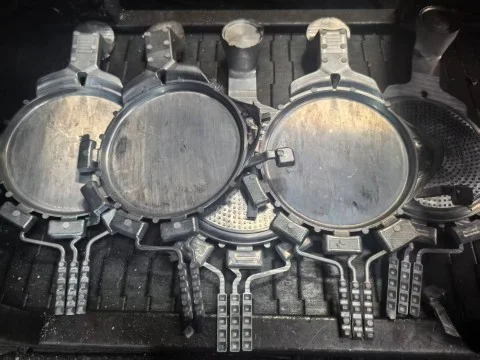

The Core Manufacturing Process for Aluminum Road Studs: Die Casting

The exceptional performance of aluminum road studs is highly dependent on advanced die casting technology. This process is fundamental not only to the product’s shape but also to its internal density, mechanical strength, and dimensional accuracy.

- Near-Net Shape: Die casting produces parts with high dimensional accuracy and good surface finish, significantly reducing the need for subsequent machining. This lowers overall manufacturing costs and material waste, aligning with the economic principles of mass production.

- High-Pressure Forming: Molten aluminum is injected at high speed and pressure into a steel mold, instantly and precisely filling the complex cavity. This perfectly replicates all details, including reflective grooves and mounting clips, ensuring high consistency across production batches.

- Rapid Solidification: The metal cools quickly within the mold, forming a uniform and fine-grained microstructure. This structure provides outstanding impact resistance, enabling the stud to withstand the dynamic load of repeated vehicle traffic, not just static pressure.

Advantages of Haichen Aluminum Die Casting Machines in Road Stud Manufacturing

The advantages for casting road studs with the Haichen aluminum die casting machine are as follows:

- Precision: The value of the machine increases with its second operation. The casting of the aluminum in the defined borders infilling all the contours increases the road stud precision.

- Durability: Road studs manufactured from die cast aluminum are very dependable, as they are able to withstand years of stress from vehicles driving over them, as well as exposure to heat, water, and other weather conditions.

- Customization: Complex customized designs for road studs in all different styles and sizes can easily be done due to broad adaptability of the machines.

- Case Study in High-Volume Production: For instance, a traffic safety product exporter, fulfilling a large-volume order for heavy-duty aluminum road studs for the North American market, utilized HAICHEN’s HDC-800 cold chamber machine. The machine’s 880-ton clamping force ensured the large studs maintained dimensional stability under high-pressure injection. By integrating an automated spraying and extraction system, the production line achieved 24/7 continuous operation, reducing the unit cycle time by 18% while maintaining a product defect rate below 0.5%. This robustly ensured on-time delivery and superior quality for the order.

Other Innovations in Producing Road Studs

With the development of infrastructure in smart cities, it becomes possible to include:

- LED lights powered by the sun

- Automatic smart traffic sensor

In favor of such innovative steps, Haichen perpetually perfects die casting technology, supplying:

- Energy-efficient machines

- Automation-ready systems

- Enhanced alloy compatibility

Material for road studs is very important, and aluminum alloy material has many advantages.

Manufacturers can create long-lasting road studs that are also highly visible and resistant to the elements, it all comes down to choosing the right materials.