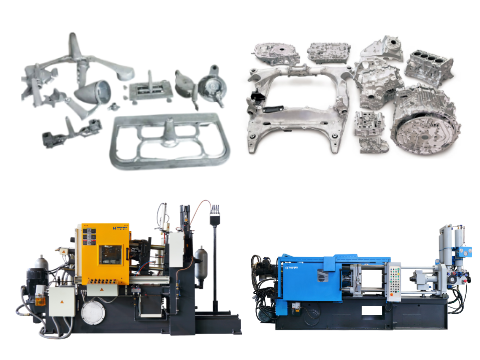

Die casting products including:

- Automotive Industry

- Consumer Electronics

- Building and Construction

- Medical Devices

- Aerospace

- Sporting Goods

- Industrial and Telecommunications

- Other Products

Other products include medical devices, hardware, and even elements in energy systems.

Die casting is widely used across various industries due to its ability to produce complex parts with high precision.

Die casting is a widely used and highly efficient manufacturing process, which can be employed to produce various high-quality metal components.

At Haichen Machinery, we specialize in manufacturing high-quality die casting machines and customizing die casting molds for our clients.

In order to ensure that their production lines possess durability, high precision, and cost-effectiveness among other advantages.

What is Die Casting?

First, the die casting process melts metal from solid to molten.

Then, similar to other molding methods, a die casting machine injects the molten metal into a mold that consists of two parts, and a hydraulic press clamps them together.

Operators either heat the metal or let it cool as it flows into the cavity between the two parts, depending on the product being manufactured.

Additionally, workers sometimes water-cool the parts through a process called “quenching” to speed up solidification and produce more products in less time.

Since die casting produces low-cost and high-volume light metal components, manufacturers commonly use fully automated and intricate production lines that can consistently create highly precise and strong metal components.

Haichen can provide customers with one-stop services for die casting machines, auxiliary machines, and customized molds.

Die casting products

- Automotive Industry

- Consumer Electronics

- Building and Construction

- Medical Devices

- Aerospace

- Sporting Goods

- Industrial and Telecommunications

- Other Products

It is a versatile manufacturing process used to produce a wide range of products across various industries.

Automotive Industry

- Engine Components: Cylinder heads, engine blocks, and pistons.

- Transmission Components: Gearbox housings and transmission cases.

- Body Parts: Wheel rims, door handles, and chassis components.

- Safety Components: Seat belt latches and ignition housings.

Consumer Electronics

- Computer Components: CPU heat sinks, computer casings, and connectors.

- Mobile Devices: Smartphone and tablet housings.

- Camera Bodies: Lightweight and durable housings for cameras.

Building and Construction

- Hardware: Door handles, hinges, locks, and window fittings.

- Lighting Fixtures: Lamp bases, shades, and outdoor lighting components.

Medical Devices

- Surgical Instruments: Precision tools and equipment.

- Medical Equipment: Gearboxes for hospital beds, monitors, and parts of medical pumps.

Aerospace

- Engine Parts: Turbine blades, engine housings, and structural components.

- Aircraft Components: Lightweight yet strong parts for aircraft interiors and exteriors.

Sporting Goods

- Golf Club Heads: Precision-molded components for performance.

- Bicycle Frames: Lightweight and durable frames.

- Fishing Reels: Components that require high strength and corrosion resistance.

Industrial and Telecommunications

- Pump and Compressor Parts: Components like pump housings and air compressors.

- Telecommunications Equipment: Antenna mounts, RF filters, and electrical housings.

Other Products

- Toys: Durable and detailed toy parts.

- Power Tools: Lightweight and strong housings for tools.

Die casting is favored for its ability to produce complex shapes with high precision, dimensional accuracy, and excellent surface finish, making it an ideal choice for industries requiring high-quality and consistent parts.

Haichen Zinc alloy die-cast door handles case

Zinc alloy die-cast door handles are a durable, versatile and highly popular choice, suitable for both indoor and outdoor doors, including sliding patio doors.

They are renowned for their strength, economy, and the ability to be manufactured in various modern or traditional styles (such as powder coating or chrome).

Die-cast handles offer excellent safety, precision, and are typically provided in a complete set,

Including internal and external handles, capable of fitting various thicknesses and hole spacings of doors, and there are many non-dominant hand types available for selection, facilitating installation.

Then,Haichen can start from the design of the door handle drawings to create a high-quality complete zinc die-cast production line for customers.

Haichen aluminum road studs case

Haichen has customized many die casting molds for customers, one of which is aluminum road studs. Aluminum die-casting road studs are a kind of cast aluminum road studs used in road safety facilities.

Which have the characteristics of reflective, compressive and corrosion resistance, and are often used for road markings, reflective signs, etc.

Haichen provides customized die casting services including mold design, mold manufacturing, mold trial, and other services, which can produce engineered parts of various sizes and shapes.

And can meet special assembly and installation requirements, such as casting specified pins on components, machining external threads, casting drilling sizes for internal threads, etc.

Haichen Custom Aluminum Die Casting mentioned that when choosing custom aluminum die casting services, factors such as demand, quality, technology, lead time, sustainability.

And customer service should be considered, indicating that customized services may include full-process services from design to delivery.

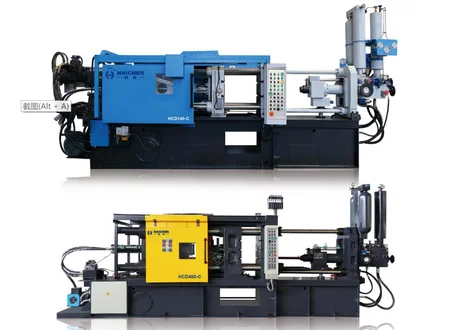

Our die casting machine

Haichen is a well-known manufacturer of die casting machines, offering both cold chamber and hot chamber die casting machines with tonnage ranging from 30 tons to 1600 tons.

Our machines can meet various industry standards, including national safety standards and CE safety standards.

The machines of Haichen export to over 30 countries and are recognized for their high performance-to-price ratio.

If there is any demand in Haichen’s die casting machines, you can contact us directly for more information on specific models and pricing.

If you’d like to learn more about this process, explore compatible materials, or discover how to implement it in your business, feel free to contact one of our representatives today.

Alternatively, simply start your quote—an experienced engineer will promptly contact you to discuss further details