The design of the die cast mold plays a vital role in the shape of the part. In addition, it affects the quality, uniformity, and configuration of the components from the die casting process.

It not only determines the shape and quality of the product.

But also directly affects the production efficiency, cost and market competitiveness of the final product.

These durable, custom-designed steel tools ensure repeatability for each cast, making the process ideal for industries like automotive and electronics where intricate components are needed in large quantities with minimal waste.

Introduction to the Die Casting Process

Die casting is a process in which molten metal, such as aluminum, zinc, or magnesium alloys.

Is injected into a permanent mold (called “dies”) under high pressure.

This process ensures that the metal completely fills the mold cavity by maintaining high pressure.

And after curing, the mould is opened to remove the finished product.

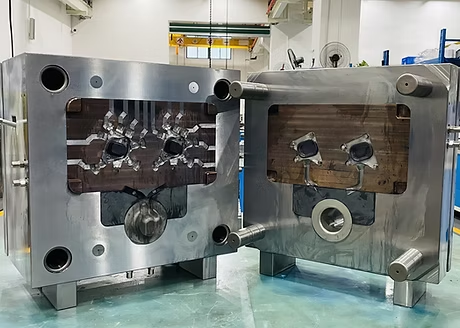

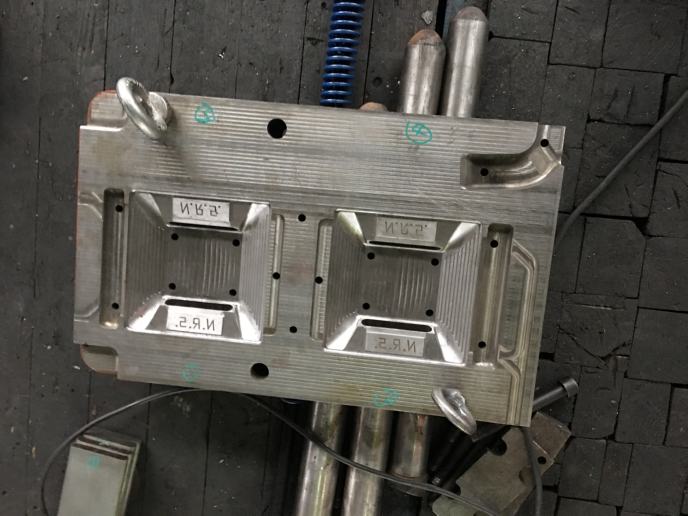

Die Casting Moulds Structure & Materials

Die casting molds are typically made up of two halves made of high-strength metals.

Such as steel or iron to ensure precise closing and opening operations.

The cavity part of the mold needs to be precision machined to ensure good dimensional accuracy and surface finish.

Die Casting moulds use and maintenance

In the die casting process, the mold needs to withstand high temperature and high pressure.

So the choice of material is very important.

For example, although the cost of cast iron molds is low, their high temperature pouring requirements are high, and it is easy to shorten the life of the mold.

Therefore, high-temperature-resistant non-ferrous materials are usually selected for molds.

In addition, the design of the cooling system of the mold is also crucial to ensure that the metal is quickly cooled and demolded.

The importance of Die Casting Moulds

- Determine the shape and size of the final product

- Influencing Product Quality and Consistency

- Increased production efficiency

- Controlling Thermal Balance and Pressure

- Defect Reduction and Surface Quality

- Adapting to the needs of complex geometries

- Extend mold life

- Reduced Production Costs

Determine the shape and size of the final product

Die casting molds are an indispensable core component in the die casting process.

And their design directly affects the shape, size and accuracy of die castings.

The shape and characteristics of the mold determine the appearance and function of the final product.

Therefore, the design of the mold must be precise and meet the production requirements.

Influencing Product Quality and Consistency

The design of the mold not only determines the shape of the die casting, but also has a significant impact on the quality, consistency, and configuration of the product.

For example, whether the cooling system design of the mold is reasonable will directly affect the cooling rate and shrinkage of the metal.

Which will affect the mechanical properties and surface quality of the product.

In addition, the strength and durability of the mold also determine whether the die casting can meet the expected quality standards.

Increased production efficiency

A well-designed mold can significantly improve production efficiency.

Proper mold design can reduce the defect rate in the production process, reduce rework costs, and shorten the production cycle.

In addition, the optimized design of the mold can also reduce material waste, which in turn reduces production costs.

Controlling Thermal Balance and Pressure

In the die casting process, molds need to withstand high temperatures and pressures.

The thermal balance management and strength of the mold limit the maximum injection pressure, which affects the stability and efficiency of the entire production process.

If the mold is not properly designed, it can lead to excessive thermal stress, deformation or damage.

Which in turn affects product quality and production safety.

Defect Reduction and Surface Quality

Improvement Details in mold design (e.g., gate location, cooling channel layout, etc.) have a direct impact on defects in die castings (e.g., porosity, craters, cracks, etc.).

Good mold design can effectively reduce these defects and improve the surface quality and overall performance of the product.

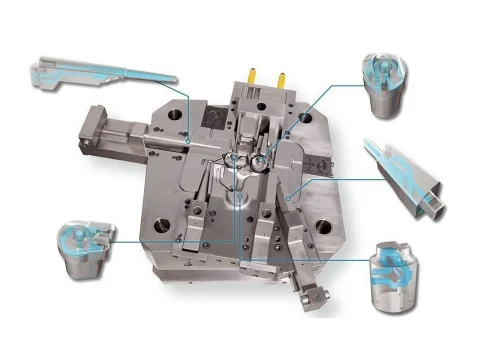

Adapting to the needs of complex geometries

Die casting molds are capable of producing parts with complex geometries and high precision requirements.

Which are difficult to achieve with other manufacturing processes.

For example, by optimizing the mold design, it is possible to manufacture thin-walled, finely structured die castings.

Extend mold life

The selection of mold materials and pretreatment, such as preheating, are critical to extending mold life.

Proper mold temperature management can reduce thermal stress and avoid cracking or deformation of the mold, thereby extending its service life.

Reduced Production Costs

While high-quality mold design and manufacturing requires a high initial investment.

Production costs can be significantly reduced in the long term by reducing scrap rates.

Increasing production efficiency, and extending mold life.

How Do Die Casting Molds Contribute to Cost Reduction in Mass Production?

Die casting molds reduce costs by spreading the high initial tool investment over hundreds of thousands of parts.

Fast cycle times, low labor costs due to automation, and near-zero material waste(runners are recycled) lead to an extremely low price per piece.

This is the conversation Haichen have most often with customers. They see the upfront cost of a new mold, which can be significant, and they get nervous.

But we have to look at the total cost of ownership. A $100,000 mold that produces 500,000 parts over its life adds only 20 cents to the cost of each part.

When you add in the savings from automation, part consolidation, and eliminated secondary operations, the business case becomes clear.

The price per piece for a die-cast part is often a fraction of what it would cost to machine it from a solid block.

For any company planning for mass production, the initial investment in a high-quality die casting mold pays for itself many times over.

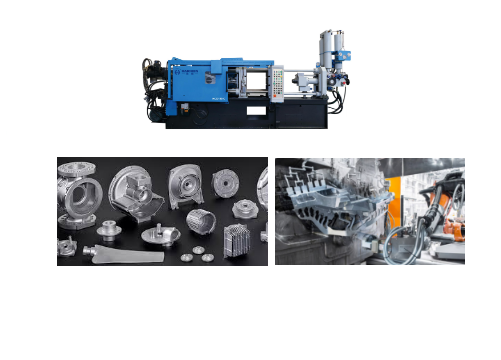

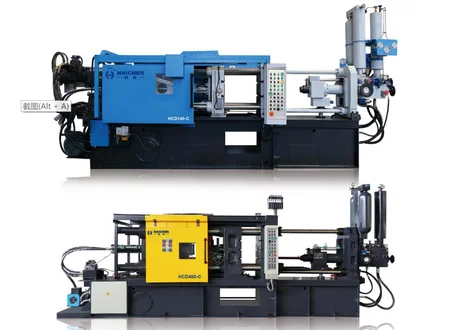

Why choose Haichen‘s die-casting machine?

With over 20 years of experience, Haichen offers:

- Specialization in design and mold manufacturing: From 3D modeling to finite element analysis, we ensure that the mold performance reaches the optimal state.

- Precision manufacturing: Even the most complex parts can achieve extremely small tolerances and high-quality surface treatment.

- Comprehensive support: We fully configure the die-casting machine for you and guide you through every step.

- CE certification quality: Provide die-casting machines that meet the highest performance and reliability standards.

Is die-casting suitable for you?

If you are considering using die-casting for your next project, please contact Haichen immediately.

Let us help you determine if die-casting is suitable for your needs and guide you to find the best solution that meets your requirements.