Ladle is an important auxiliary machine in the automated production process of die casting.The use of casting ladle in the die casting process is not only to transport molten metal from the furnace to the mold, but also involves improving production efficiency, controlling metal flow, reducing defects, extending mold life, and improving safety.

The die-casting ladle replaces the traditional manual soup feeding method through automated operation, significantly improving production efficiency.

Ladler has smooth movements, stable and accurate soup volume, and can achieve high-speed operation and stop, avoiding errors and time waste in manual operation.And this is the biggest advantage of modern automated production.

Key points of the ladle in the field of die-casting applications

We use to give the use of ladle is mainly for the reason:

- Temperature control:

- Reduce heat loss

- Improve pouring efficiency

- Process control:

- Safety and maintenance:

Temperature control

In the die casting process, when the molten metal is poured from the ladle into the nozzle, the temperature of the metal will drop significantly.

Which may lead to defects in the casting, such as irregular flow lines.

By optimising the pouring rate of the ladle,we can reduce this temperature to drop , thus guaranteeing the quality of the casting.

Reduction of heat loss

The design of the pouring ladle usually includes insulation measures to reduce heat loss during transport of the molten metal.

This is essential to maintain the stability of the temperature and chemical composition of the metal and helps to improve the quality and productivity of the castings.

Improved pouring efficiency

The ladle allows the molten metal injecting into the mould in a rapid and continuous manner, which is essential for achieving high speed, large scale production.

By optimising the design and operation of the pouring ladle, it is possible to further increase pouring speed and stability, reduce air inclusions and the formation of cured layers, and thus improve the quality of the castings.

Process control

The ladle is not only used to transport the molten metal, but also to control the flow and temperature of the metal through its design and operation.

For example, the shape and size of the ladle can affect the stability and uniformity of the metal flow, which in turn affects the quality of the casting.

Safety and maintenance

The use of ladles reduces the direct contact of the operator with the hot molten metal and improves safety in the workplace.

At the same time, the design of the ladle is usually considered easy to clean and maintain

Which helps to extend the life of the equipment and reduce maintenance costs.

The use of ladles in the die casting process is designed to ensure temperature and quality control of the molten metal.

Improving productivity and casting quality, while ensuring operational safety and equipment maintenance.

How does the use of ladle reduce heat loss in die casting?

The use of ladle is using in minimise heat loss from die casting in several ways:

- Preheating and insulation

- Optimising ladle management and operation

- Improvement of the ladle’s permanent lining

- Use of advanced ladle heating technology

- Optimisation of the ladle heat trace model

Preheating and insulation

Reduce heat loss from the molten metal to the environment by preheating and using insulating materials.

For example, the use of ceramic paper as an insulating material can effectively control heat loss from the ladle. In addition, the use of lightweight cast plastisols as a permanent layer material can increase the average temperature of the molten steel and reduce the rate of temperature drop, thus reducing heat loss.

Optimisation of ladle management and operation

By optimising ladle management and operation, e.g. by adjusting the heating parameters of the ladle.

Metallurgical process can be significantly influenced, thus reducing energy consumption and heat loss.

The implementation of automatic ladle cover equipment and optimisation of measures such as slag washing, top slag modification, submerged arc operation and heating modes can control excessive drops in molten steel temperature during the process, thus reducing heat losses.

Improvement of the permanent lining of the ladle

By improving the permanent lining material of the ladle, e.g.

By using mullite refractory with high strength and high thermal insulating properties and by reducing the thickness of the permanent lining, the temperature loss can be reduced and the heat retention effect of the ladle can be improved.

Adoption of advanced ladle heating technology

Ladle heating technology with sealed, recuperative combustion systems can increase the thermal efficiency from about 10 per cent of the current system to 60 per cent or more, thus reducing fuel costs and shortening the heating cycle.

Centralised ladle preheating systems use heat exchangers and hermetic heating to minimise losses, allowing foundries and small steel mills to reduce energy costs for ladle preheating.

Optimisation of the ladle heat trace model

By building a ladle heat trace model and combining it with a ladle thermal condition test and numerical simulation of the ladle heat transfer, it is possible to analyse the factors influencing the temperature of the molten steel.

Factors such as preheating time, cooling time and offline preheating time of a new ladle can be analysed in order to reduce heat loss.

Heat loss during the die casting process can be effectively reduced by preheating and holding, optimising ladle management and operation, improving the permanent lining of the ladle, using advanced ladle heating technology and optimising the ladle heat tracking model.

How the use of a ladle improves the efficiency of die-casting production?

The ways in which the use of a ladle (soup feeder) improves the efficiency of die casting production are these five areas in particular:

- Automated and programmed production

- Improvement of the accuracy of the stock picking process

- Reducing energy consumption and costs

- Increased production speed and flexibility

- Optimising ladle positioning

Automated and programmed production

Instead of manual soup picking, automatic soup feeders automate and program the die casting production line, reducing the need for manpower and increasing production efficiency and safety.

This automated equipment allows precise control of the soup feeding process, ensuring the cleanliness, temperature and accuracy of the metal slurry, thus improving the quality of the die castings.

Improve the accuracy of the soup-taking process

By adopting advanced mechanical design theories and methods, such as the motion analysis and optimisation simulation of the five-lever automatic soup-taking machine, the soup-taking process can be improved by expanding the soup-taking stroke and improving the smoothness of the motion.

This optimisation not only improves efficiency, but also ensures the consistency and quality of the die castings.

Reduce energy consumption and cost

By adopting technologies such as centralised ladle preheating system, energy consumption can be effectively reduced and energy cost can be reduced.

The use of new technologies such as electromagnetic induction heating systems can further improve the cleanliness of liquid steel without increasing the contamination of conventional sand nozzles, thus reducing the need and cost of additional heating.

Improve the production speed and flexibility

Through the development of a machine dual-arm spray pickup robot control system and other technologies, can achieve the die-casting production process of scooping soup, pickup, spray three major processes of automation and intelligence, significantly improve the production speed and flexibility.

The high precision and flexibility of this system makes the production of different types of moulds more efficient and flexible.

Optimisation of ladle positioning

By optimising the positioning of the ladle in the automatic pouring machine, it is possible to ensure that the molten metal injecting into the mould quickly and accurately, avoiding any shaking of the liquid metal, thus improving the accuracy and efficiency of the pouring process.

The use of a ladle (soup feeder) significantly improves the efficiency and quality of die casting production by automating and programming the production, increasing the accuracy of the soup pick-up process, reducing energy consumption and costs, increasing the speed and flexibility of production and optimising the positioning of the ladle.

How does ladle help in process control of die casting products?

Ladle’s help in process control of die casting products is mainly in:

- Temperature control

- Fluidity management

- Automation and efficiency enhancement

- Quality assurance

- Cost-effective

Temperature control

ladle’s temperature control of the metal fluid in the die casting process is crucial. By precisely controlling the temperature of the metal liquid, can ensure the quality and performance of die casting.

For example, through the use of automatic soup feeder, it can reduce the error of human operation and improve the accuracy and stability of temperature control.

Fluidity management

Ladle affects the filling process of die casting by controlling the flow of metal liquid.

Good flowability can reduce defects in die castings, such as cold segregation and porosity.

Automation and efficiency improvement

Automatic ladle can replace the human to complete the soup operation, not only improve the production efficiency, but also enhance the safety and reliability of the production process.

The automation system can also optimise the production process and reduce downtime through real-time data monitoring and adjustment.

Quality Assurance

By accurately controlling the composition and temperature of the metal fluid, ladle helps to improve the overall quality of die castings.

For example, after adjusting the chemical composition of the metal fluid and removing impurities, the mechanical properties and durability of the die castings are much more better.

Cost-effective

Ladle can reduce the waste of raw materials, reduce energy consumption, and reduce production costs by reducing labour errors.

Ladle plays a key role in the process control of die casting products, not only improves the production efficiency and product quality, but also helps to reduce costs and improve safety.

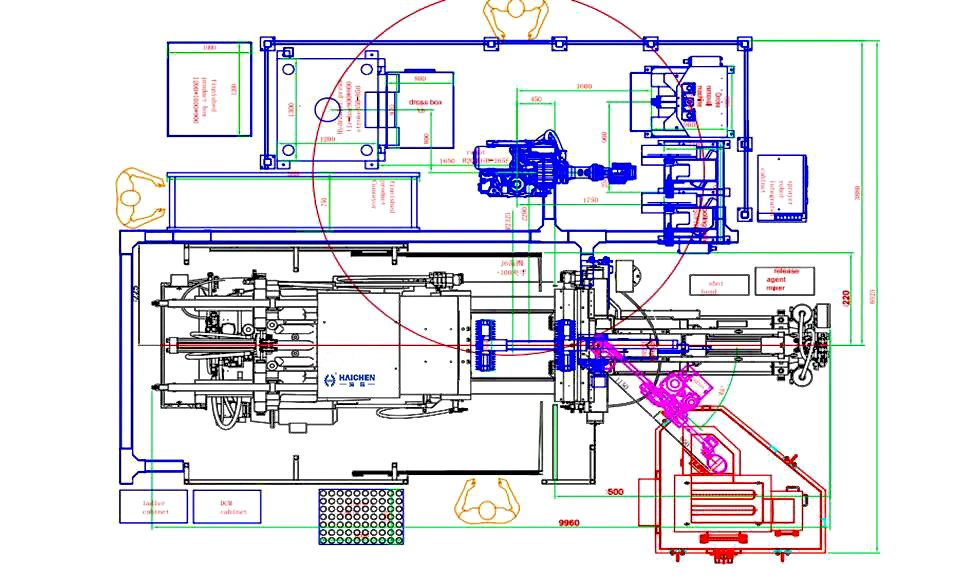

Haichen’s high-quality Ladle will serve you well in your die casting production

The Haichen high quality Ladle with a variety of advanced technological features and is ready to be personalised for your die casting production:

- High mobility and precision

- Easy to operate and maintain

- High precision and stability

- Strong adaptability

High mobilisation and precision

Haichen’s servo die casting Ladle completely eliminates manual operation and is closely integrating with the die casting machine production.

Which improves production efficiency and precision.

In addition, the machine uses an independent gear motor to directly drive the worm gear box for smooth, precise and efficient operation.

Easy operation and maintenance

Haichen’s Ladle equiping with touch-type man-machine interface, parameter settings at a glance, and with self-diagnostic function of faults, so that the operation and maintenance is extremely easy.

These features ensure the efficiency and reliability of the equipment in actual use.

High precision and stability

Haichen’s die-casting machine Ladle adopts servo control, which is able to realise high-speed, stable and high-precision soup feeding operation.

This not only improves product quality, but also reduces the defective rate.

Strong adaptability

Haichen’s Ladle design takes into account the different sizes of ejection barrels.

Which can adapt to a variety of die casting needs. Its beam type design solves the problem of unstable moving path of ladle in traditional soup feeder, and further improves the liquid material transport efficiency.

Haichen’s high quality Ladle (soup feeder) can indeed provide excellent service for die casting production through its automation, high precision, easy operation and adaptability.