Process Cost of Die Casting alloys

Process Cost of Die Casting alloys has several parts: The process cost of die-castings involves multiple factors, including material cost, mold cost, manufacturing cost, post-treatment cost, etc. Material cost is a major component, and the price fluctuates according to market conditions and the weight and volume of the casting. Manufacturing costs are influenced by machine […]

What are the casting characteristics of die casting alloys

Die casting alloys casting characteristics mainly includes flowability, dimensional accuracy and surfaces finish, mechanical property, high temperature resistance,etc. Die casting alloys (die casting alloys) is used for die casting process of metal materials, mainly including aluminum alloys, zinc alloys, magnesium alloys, and some special alloys. These alloys are widely used in various industrial fields because of their […]

What are applications of die casting alloys?

Die casting alloys applications are in many industries like automotive industry, aerospace industry, consumer electronics and other industries. Die casting is a process widely uses in multiple manufacturing industries to produce metal parts with complex geometry, high precision and good surface quality. The application areas of die casting are very wide, covering a variety of […]

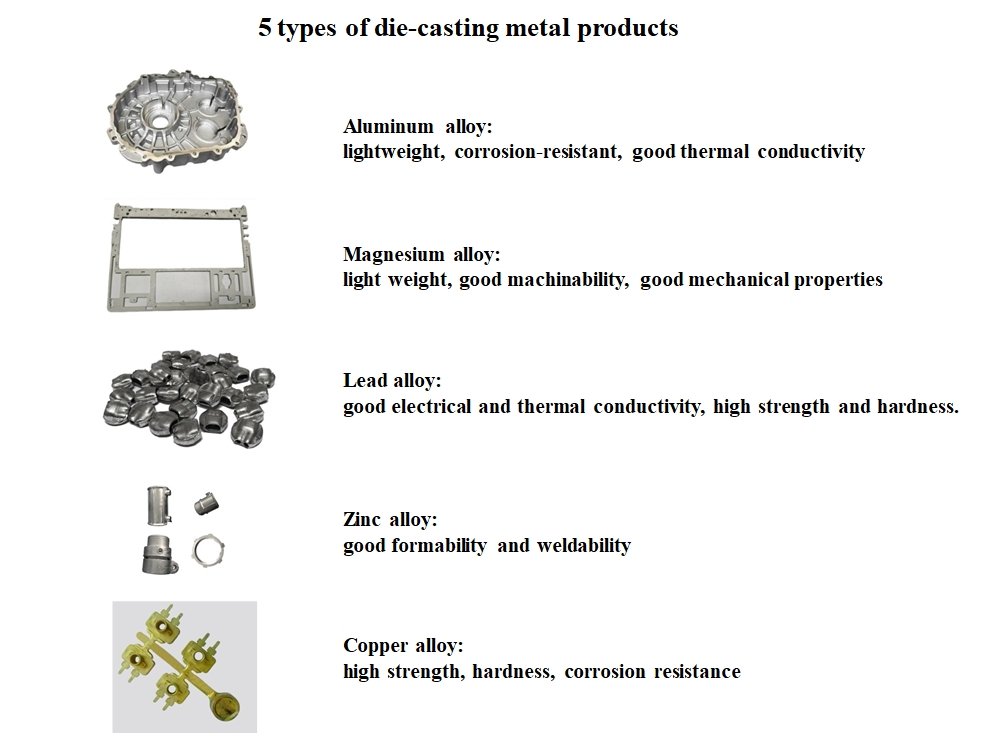

What are Die Casting Alloys?

Die casting alloys refer to the metal material made by injecting molten metal into the mould through high pressure. They mainly include aluminium alloys, zinc alloys, lead alloys, magnesium alloys and copper alloys. These alloys have good die-casting properties, corrosion resistance, high strength and low density, and are widely used in automotive, aerospace, electronic equipment […]

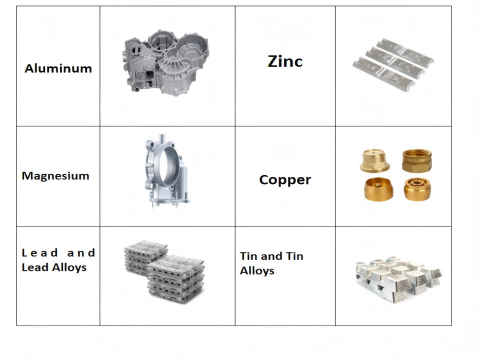

What are the Most effective alloys for Die Casting

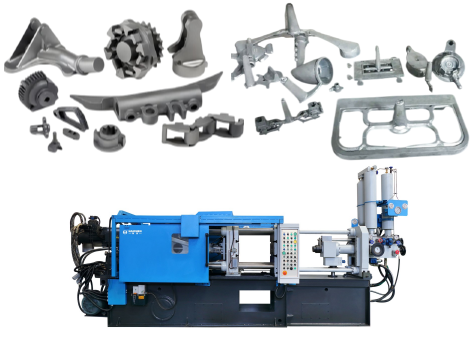

The most effective alloys for die casting include aluminum, zinc, magnesium, copper, tin, and lead alloys, each offering unique properties for specific applications. Die casting is a metal casting method that forces molten metal into a mold with high pressure. The machine was utilized to manufacture metal components extremely accurately and repeatedly. Hence, the choice of alloy is […]

How much power does a die casting machine consume?

Die casting machine consume limit value of a certain die-casting machine is about 50 kW·h, and the energy consumption per cycle is about 1kW·h/cycle. Die-casting machines are mainly divided into two types: hot chamber and cold chamber. Different types of machines are suitable for metals with different melting points. For instance, hot chamber machines are […]