High pressure die castingcan produce complex shapes with intricate details and thin walls, and the castings usually have a smooth surface after they come out of the mold. It can handle tighter tolerances and produces much less scrap than other similar methods. It is compatible with a wide range of non-ferrous metals and is cost-effective when produced in large quantities.

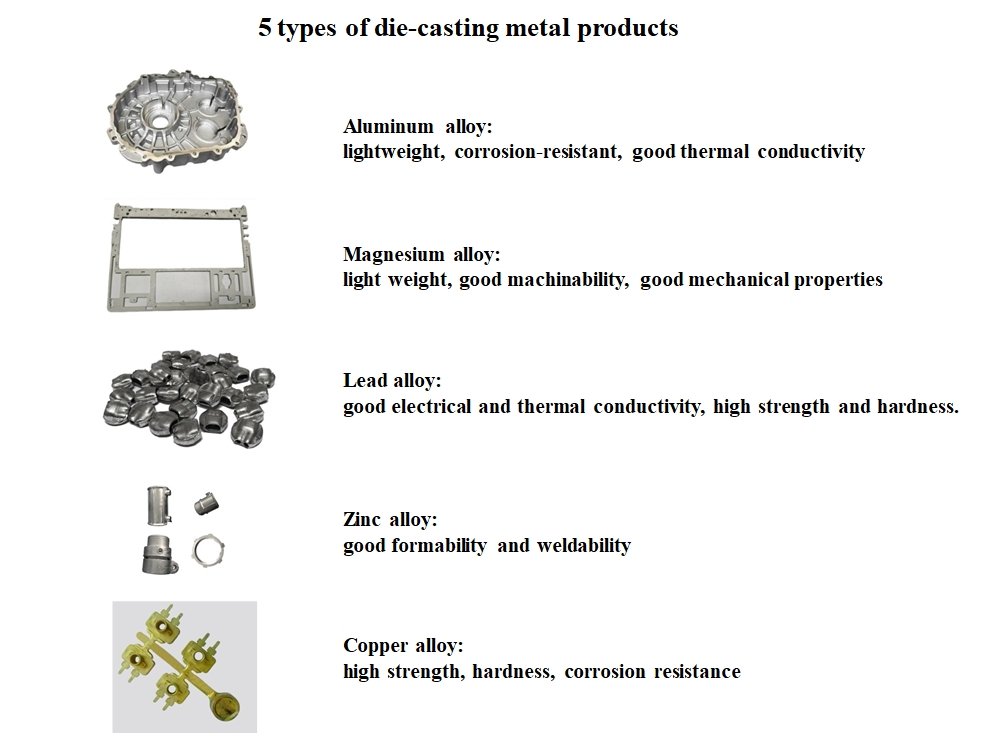

The three main metal groups used in this die casting process are aluminum, zinc, and magnesium.These metal accessories made of these materials can provide various customized assistance to automobiles, aviation, and mechanical industries.

High Pressure die Casting (HPDC) is a manufacturing process used to produce complex, high precision metal parts for a wide range of industries. High pressure casting products are mainly:

Common die casting product industries

- Automotive and motorbike industry products

- Aerospace products

- Electronics industry products

- Consumer products

- Home appliances and kitchen appliances

Automotive and motorbike industry

High pressure casting is commonly using to produce automotive and motorbike parts, such as engine blocks, gearbox housings, wheels, etc.

Aerospace

In the aerospace industry, high pressure casting is using to produce parts that require high strength and light weight, such as aircraft structural parts.

Electronics industry

In the electronics industry, high-pressure casting is using to manufacture heat sinks, connectors and electronic equipment housings, which require good thermal conductivity and electromagnetic shielding properties.

Consumer products

High pressure casting is also using to produce parts for consumer products.

Such as camera brackets, headphone frames, tablet frames, etc.

Home appliances and kitchen equipment

In home appliances and kitchen equipment, high pressure casting is using to produce some key parts, such as rice cooker shell, oven parts, etc..

Other applications

High pressure casting in the production of lift treads, warehouse automation robot chassis and so on.

High-pressure casting is used in a wide range of applications due to its ability to quickly and efficiently produce parts with complex geometries and high precision.

What Automotive products are made by high pressure die casting?

High Pressure Die Casting (HPDC) technology is widely used in the automotive industry to manufacture a wide range of structural components in aluminium and magnesium alloys.

It is mainly involved in the following products

- Engine components

- Transmission components

- Body structure parts

- Suspension components

Engine components: such as engine blocks, cylinder heads, crankcases, etc.

Transmission components: e.g. gearbox housings.

Body structure components: e.g. frame cross member, battery case, etc.

Suspension system components: such as shock absorber bracket.

High-pressure die casting is using to manufacture some lightweight components to improve the fuel efficiency and overall performance of vehicles.

This technology is favoured for its high precision, excellent surface finish and outstanding mechanical properties.

And is often used for the high volume production of complex metal parts.

Which aerospace products are manufactured by high pressure die casting?

High Pressure Die Casting (HPDC) is widely for in the aerospace industry to manufacture a variety of critical components. Respectively:

- Aero-engine components

- Structural components

- Landing gear components

- Other critical components

Aero-engine components

High-pressure die-casting technology is using to produce precision components for aero-engines, such as turbine blades and compressor components.

These components require high strength and precision to ensure the reliability and safety of aviation systems.

Structural components

Structural components of aircraft, such as fuselage and certain parts of the wing, are also making by high-pressure die-casting process.

These components typically require lightweight and high strength to improve the overall performance and fuel efficiency of the aircraft.

Landing gear components

Landing gear is an important part of the aircraft and its manufacture also relies on high pressure die casting technology.

This technology enables the production of complex design components that meet stringent quality requirements.

Other key components

In addition to the above components, high pressure die casting is using in the production of other key components in the field of aviation.

Such as combustion chamber bazooka and magazine, etc..

These components work at high temperatures and pressures, and therefore have extremely high requirements for materials and manufacturing processes.

High-pressure die-casting technology plays an important role in the aerospace field because of its high precision.

High strength and lightweight characteristics

What appliances and kitchen equipment can be produced with high pressure die casting?

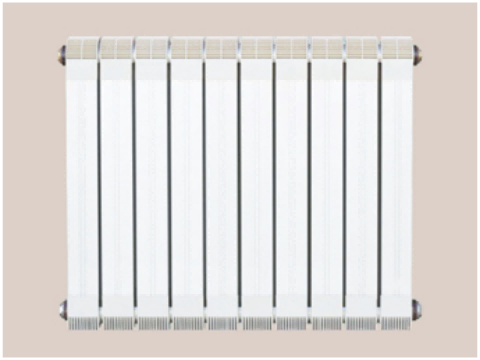

High-pressure die casting technology can produce a wide range of home appliances and kitchen equipment products.

- Household appliances

- Kitchen appliances

- Other kitchen equipment

Household appliances

Many metal parts in home appliances such as televisions, washing machines, air conditioners, etc., such as shells, bases, sockets, etc., are manufactured by high-pressure die casting process.

Other common household appliance parts, such as refrigerators, microwave ovens, rice cookers, etc., can also be produced by high-pressure die-casting process.

Kitchen utensils

Cookware: high pressure die casting technology can be used to produce all kinds of cookware, such as pans, frying pans and so on.

Oven parts: high pressure die casting can produce various parts of the oven, these parts usually need good heat resistance and durability.

Coffee machine parts: high pressure die casting technology is also suitable for coffee machine parts manufacturing, such as coffee machine shell and other metal parts.

Other kitchen equipment

Heating discs, electric heaters, etc. in commercial kitchen equipment can also be produced by high-pressure die casting, and these parts usually require high precision and good durability.

Die casting technology is also used to produce other components of commercial kitchen equipment, such as gas cookers, stove accessories and so on.

High-pressure die casting products in the electronics industry

High-pressure die casting a strong technique in the electronics industry, mainly for the production of a variety of high-precision, high-complexity metal parts.

Such as computers, mobile phones and other electronic devices of these key electrical components.

- Heat sink

- Connector

- Shell

- Other precision parts

Heat sinks

High-pressure die-casting technology is widely using in the manufacture of electronic equipment in the heat sink, such as computers, mobile phones and cameras and other equipment heat dissipation components.

These heat sinks are usually made of aluminium alloy, which ensures the stability and reliability of the equipment due to its good thermal conductivity and corrosion resistance.

Connector

High-pressure die-casting a may technique in the production of electronic equipment in the connector, these connectors need to have high precision and high reliability, in order to ensure that the reliable electrical connection between the electronic components.

Shell

High-pressure die-casting technology is using in the manufacture of electronic equipment shell, such as laptop computers, smart phones and camera shell.

These housings not only need to have high strength and durability, but also need to have good surface finish and design flexibility.

Other precision parts

In addition, high-pressure die-casting is for the production of other high-precision electronic components, such as LED lamps and lanterns in the radiator, aluminium electrolytic capacitor shell, and smart bracelet and electronic watch metal shell.

High pressure die casting technology plays an important role in the electronics industry, through its high precision, high efficiency and material diversity and other advantages, for the manufacture of electronic equipment to provide strong support.

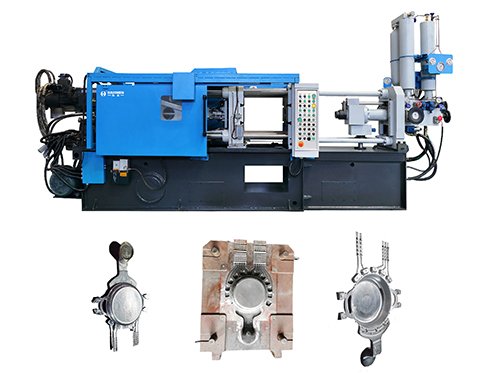

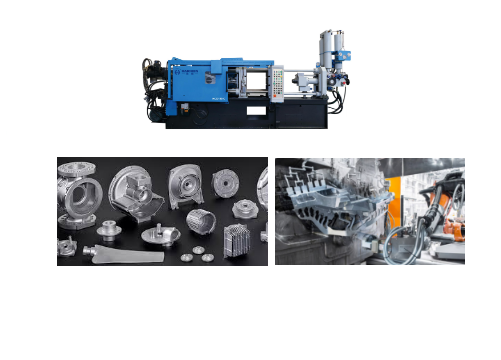

Haichen high pressure die casting machine for you to solve the production of all kinds of metal products

Haichen High Pressure Die Casting machines offer significant advantages in solving production problems for all types of metal products.

Firstly, high-pressure die casting (HPDC) is a highly efficient manufacturing process capable of producing geometrically complex, high-precision metal parts, and is particularly suited to the mass production of products with high dimensional accuracy and excellent surface finish.

By injecting molten metal into the mould cavity under high pressure, this technology significantly reduces the internal porosity of the casting and improves the integrity and mechanical properties of the casting.

In addition, Haichen high-pressure die casting machines equiping with a variety of innovative features, such as dual closed-loop.

Fully real-time control of the injection system, which ensures a high-quality, highly stable injection process.

These systems use advanced control systems, such as Siemens SIEMENS control systems, to achieve precise control of casting pressure and injection speed.

Thus ensuring high quality and consistency of die castings.

In terms of application areas, Haichen high pressure die casting machines are using in automotive, communications, 3C electronic products, aviation, building materials and other fields to meet the demand for high-performance, high-precision metal parts in these industries. For example, in the automotive field.

Haichen high-pressure die casting machine for the production of super-large die casting parts to provide reliable equipment support, help automotive lightweight and industrial development.

Haichen high pressure die casting machine through its efficient manufacturing process and advanced control system, for all kinds of metal products production provides a reliable solution, especially in the need for high precision and high complexity of parts manufacturing outstanding performance.