High pressure die casting benefits mainly includes high precision, production efficiency, reduce costs and others so on.

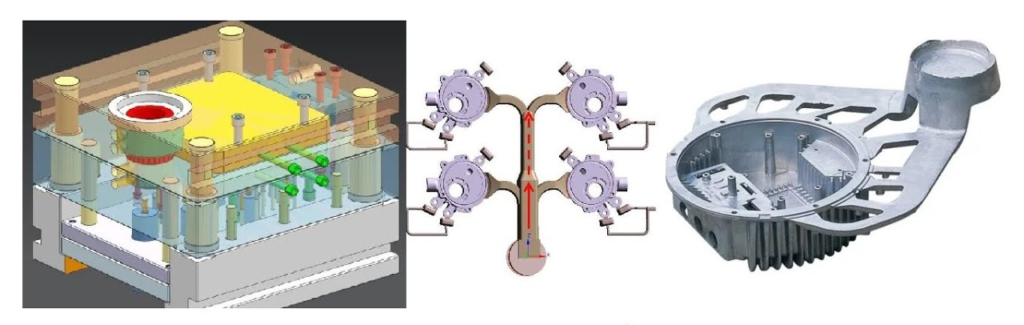

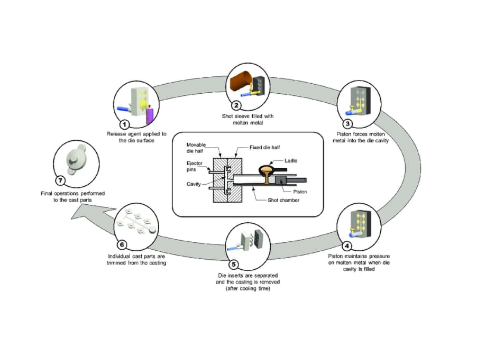

High Pressure Die Casting (HPDC) is an advanced manufacturing technology known for its high precision and complex geometry production capabilities. This technology injects molten metal into a precision mold under high pressure, which can achieve high precision and complex shapes of parts while reducing the need for subsequent processing, thereby improving production efficiency and reducing costs.

High pressure die casting (HPDC) offers several significant advantages that make it a preferred process for manufacturing complex metal parts. Here are 8 main details benefits:

- High Precision and Complex Geometries

- High Strength and Durability

- High Production Efficiency

- Cost-Effectivenes

- Reduced waste and material costs

- Reduced porosity

- Flexibility and versatility

High pressure die casting technology has become an indispensable part of modern manufacturing industry with its high precision and complex shape production capabilities. With high pressure die casting machine, its benefits are not only reflected in the manufacturing quality of parts, but also in production efficiency and cost-effectiveness. Making it widely used in the fields of automobile, aerospace, electronics, etc.

High Precision and Complex Geometries

- High Precision

- Complex geometries

High Precision

High pressure die casting is able to achieve extremely high dimensional accuracy, mainly due to its use of precision molds and high-pressure injection technology. For example, HPDC high pressure die casting machine can produce parts with a tolerance of only ±0.002 inches while maintaining consistent dimensions and surface quality. This high precision eliminates the need for additional machining or adjustments during the manufacturing process, saving time and costs. In addition, due to the high durability of the mold, dimensional consistency during repeated production is also guaranteed.

Complex geometries

High pressure die casting is well suited for manufacturing parts with complex shapes and thin-walled structures. For example, it can produce parts with complex internal structures and details, such as parts with grooves, holes and inserts.

This technology can directly produce parts close to the net shape, thus reducing the need for subsequent processing, such as cutting and grinding. In addition, HPDC can also produce parts with complex geometries and high-precision details, which are difficult to achieve with traditional manufacturing methods.

HPDC is to produce parts with complex geometries and fine details, including thin walls, small features, and internal structures, which are critical to the automotive and aerospace industries. Thisprocess ensures dimensional accuracy and stability of the parts while maintaining close tolerances.

High Strength and Durability

- High Strength

- Durability

High Strength

High-pressure die casting processes can produce high-strength parts, such as aluminum and zinc alloy castings, with a tensile strength of up to 415 MPa, which makes them excellent when subjected to high stresses. In addition, because the metal cools and solidifies quickly under high pressure, the microstructure of the casting is denser, thereby improving its strength and toughness.

Durability

High-pressure die-cast parts generally have a long service life due to their high precision and uniformity. For example, the mold itself is highly durable and can be reused for multiple production cycles, thereby reducing production costs. At the same time, because the metal cools quickly under high pressure and fills the mold, the surface quality of the casting is excellent, reducing the need for subsequent processing, which further improves durability.

By controlling the cooling process, HPDC can produce a fine grain structure that enhances the mechanical properties of the casting, giving it excellent strength and durability.

High Production Efficiency

- Fast production speed

- High production volume

Fast production speed

High pressure die casting significantly shortens the production cycle by injecting molten metal into the mold at high speed. For example, the injection speed of HPDC can reach 10 to 120 meters per second, and the filling time is only 0.01 to 0.2 seconds, which makes it a significant advantage in large-scale production

In addition, compared with other casting processes (such as low-pressure casting), HPDC can achieve higher production speeds, thereby improving production efficiency.

High production volume

High pressure die casting is suitable for large-scale production, especially in the case of large-scale production of more than 3,000 pieces, its economical effect is particularly significant. Due to its fast production capacity and high durability of the mold, HPDC can produce a large number of parts at a lower cost, thus further improving production efficiency

HPDC allows for the rapid production of complex parts suitable for large-scale production. This benefit is the high metal injection rate and fast production cycle time increase overall productivity. Especially suitable for high-demand production environments.

Cost-Effectiveness

It is generally more cost-effective than other casting methods due to its high productivity and less need for post-processing. This reduces the need for secondary operations such as welding or machining, thereby reducing overall manufacturing costs.

Large-scale production reduces unit costs

- HPDC significantly reduces unit costs through high-speed automated production (e.g., cold-chamber die-casting machines can produce up to 1,000 casts per day, and hot-chamber die-casting machines can produce up to 15,000 casts per day).

- High production volumes and short cycle times significantly reduce unit costs for large orders, making it particularly suitable for high-volume production in industries such as automotive and electronics.

Reduced material waste and secondary processing

- High-precision molding (with tight tolerances) and excellent surface finish allow parts to be used directly or require minimal machining, reducing raw material waste and subsequent processing costs.

- Complicated, thin-walled parts (up to 1mm thick) can be produced, reducing assembly requirements and further saving labor and material costs.

Mold Reuse and Automation

- Molds offer long life and are reusable, minimizing initial mold investment costs.

- Highly automated processes (automatic spraying, temperature control, and ejection systems) reduce manual intervention, improve efficiency, and lower operating costs.

Reduced waste and material costs

High pressure casting reduces the generation of scrap because the molten metal is injected directly into the mold, reducing unnecessary material waste.

High material utilization and minimal waste

- The HPDC process precisely injects molten metal into the mold cavity using high pressure, significantly reducing material overflow and flash, thereby lowering waste rates.

- Waste primarily comes from the gating system (such as runners and overflow chutes), but this metal is 100% recyclable, creating a closed-loop production process.

Thin-wall design reduces material consumption per part

The high-pressure characteristics of HPDC allow for the production of thin-walled parts (e.g., automotive parts with wall thicknesses as low as 0.5mm).

This significantly reduces material consumption per part while maintaining structural strength, directly lowering raw material costs.

Reduced porosity

High pressure casting fills the mold cavity with high pressure, minimizing porosity and ensuring the durability and integrity of the casting.

High Pressure Forces Out Gases

The core mechanism is that the high injection pressure forces molten metal into the mold cavity under intense pressure.

This displaces trapped air and gases, minimizing the formation of gas pores and shrinkage cavities in the final casting. This results in denser, more durable components .

Rapid Solidification Minimizes Porosity

The turbulence created during high-speed injection promotes very fast solidification of the metal.

This rapid cooling reduces the time available for gas entrapment and pore formation, leading to lower overall porosity .

Requires Precise Parameter Optimization

Reducing porosity is not automatic; it requires careful control of specific HPDC parameters:

Flexibility and versatility

High pressure casting is suitable for a variety of non-ferrous metals such as aluminum, zinc, magnesium and copper, giving it a wide range of application potential in different industries.

Design Freedom and Complex Geometries

HPDC can produce highly complex and detailed parts, including thin-walled structures (as thin as 0.75mm), internal features, and fine details.

Diverse Material Options

- Supports a wide range of non-ferrous metal alloys (such as aluminum, zinc, magnesium, and copper) to meet diverse requirements (strength, weight, and corrosion resistance).

- Material flexibility allows products to be optimized for specific applications (such as lightweight automotive components).

Production Adaptability

- High Production Efficiency: Fast injection cycle times (up to 15 shots/minute for cold-chamber die casting) make it suitable for large-scale production (thousands to millions of parts).

- Near-net-shape capability: Reduces secondary operations (such as machining) and subsequent processing costs.

Haichen high pressure die casging machine

We are Haichen, one Chinese manufacturer of producing high-pressure die casting machines. We produce cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features. Haichen also produce die casting machine auxiliary equipment, such as conveyor, vacuum machine, industrial robot, sprayer and so on.

High pressure casting occupies an important position in modern manufacturing. Due to the benefits of high pressure die casting, such as high precision, high strength, high efficiency and cost-effectiveness. Especially in applications requiring complex geometries and high-performance components.