Raw materials for a die casting heating bush also commonly known as Stellite alloys.

For die casting bushes, especially heating bushes in continuous casting, you need high-performance materials like Stellite alloys Stellite 6, 20.

Or specialized ceramic materials like Aluminum Titanate for wear, heat, and corrosion resistance, preventing metal buildup and ensuring long life, as opposed to standard casting metals like Al, Zn, or Mg used for the parts themselves.

In Haichen‘s past production experience, the materials required for bushings (tungsten chromium cobalt alloy, ceramics) can withstand extreme high temperatures, metal flow and wear, and will not degrade or contaminate the castings.

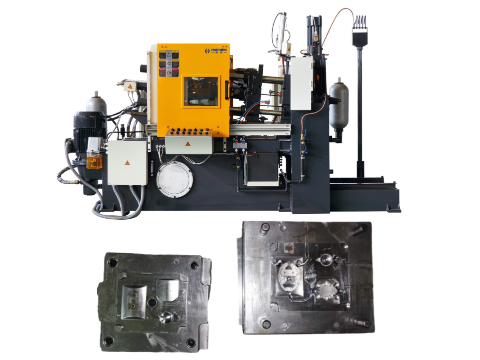

Die casting heating bush

Die casting heating bush plays a vital role in the die casting process.

Heating bush is often used to preheat molds to ensure that molds are maintained at the proper temperature during the die casting process.

Thereby improving product quality and extending mold life.

Die casting heating bush Raw Materials

- Metal materials

- Ceramic materials

- Composites

- Other Specialty Materials

Metal materials

Some die casting machine heating bush may be made of metal, such as cast iron, zinc alloy, magnesium alloy, etc.

These materials have good thermal conductivity and high temperature resistance, making them suitable for applications that require efficient heat transfer.

Ceramic materials

Some heating bush may be made of ceramic materials, especially if excellent thermal insulation properties are required.

The ceramic layer can be sandwiched between the metal layers to enhance the overall thermal stability and insulation.

High temperature resistance of ceramic materials

Ceramic materials have excellent high temperature resistance and can withstand temperatures up to more than 1200°C.

This is very important for the heating bush of the die casting machine.

Which needs to work for a long time in a high temperature environment.

Oxidation resistance of ceramic materials

Ceramic materials do not undergo oxidation reaction to metal liquids.

Which makes them very stable when in contact with high-temperature metal liquids.

Strength and toughness of ceramic materials

By adding carbon fiber mesh to ceramic materials, its strength and toughness can be significantly enhanced, and the reliability of use can be improved.

This is critical for the durability and reliability of the heating jacket.

Thermal stability of ceramic materials

Ceramic materials have a low coefficient of thermal expansion and good thermal stability.

Which helps to maintain the integrity of the structure in the face of temperature changes.

Energy-saving effect of ceramic materials

The use of ceramic internal heating technology instead of traditional external heating methods can significantly reduce energy consumption.

This is an important advantage for the heating bush of the die casting machine, as it reduces energy consumption and operating costs.

Composites

Some heating jackets may be made of composite materials, such as structures made of a combination of metal and ceramics or other insulation, to optimize their thermal properties and mechanical strength.

Thermal conductivity of composites

When the volume fraction of the metal matrix exceeds 65%, the thermal conductivity of metal composites is significantly improved, and the thermal conductivity achieves the desired effect.

This means that the composite material can efficiently transfer and dissipate heat, which is important for the design of the heating jacket of the die casting machine.

In the die casting process, the mold needs to be heated and cooled quickly to ensure the quality and production efficiency of the die casting.

The high thermal conductivity of composites can help molds reach the required temperature faster, improving production efficiency and product quality.

Heat treatment strengthening of composite materials

The traditional heat treatment process of aluminum die casting molds has some problems, such as long production cycle and complex treatment process.

The use of NQN composite reinforcement method can significantly extend the service life of aluminum die casting mold.

This shows that composite materials have significant advantages in the heat treatment process of molds, which can improve the durability and reliability of molds.

Application of composite materials in die casting molds

The design of die casting molds needs to consider the design of mold heating and cooling systems.

The application of composite materials in molds can optimize the design of these systems and improve the heating and cooling efficiency of molds.

For instance, Haichen would use composite materials to make heating sleeves to ensure that the mold is heated evenly and rapidly during the die-casting process.

Application of composite materials in automated die-casting system

Automated production system of hot chamber die-casting machine, including cylinder liner preheating, inlay, cooling and other links.

Composites can be used to manufacture these parts to improve the overall performance and efficiency of the system.

For example, composite materials can be used to create cylinder liner preheating devices to ensure that the cylinder liner reaches the proper temperature prior to mounting.

Thereby improving the quality of die castings.

Other Specialty Materials

In some special applications, the heating jacket may use other special materials, such as high-chromium cast iron, low-alloy steel, etc.

Which are often used in applications where high strength and wear resistance are required.

Haichen’s suggestion

Die casting heating bush optimize production efficiency and product quality by preheating the mold during the die casting process.

Reducing the risk of mold damage and extending the life of the mold.

Different heating methods and material options can be adapted to specific process needs to achieve the best results.