Aluminum alloys types mainly includes Al-Cu alloys, AI-Si alloys, AI-Mg alloys, AI-Zn alloys and so on.

Aluminum alloys can be classified according to their application fields, mainly into wrought aluminum alloys and cast aluminum alloys. These two types of aluminum alloys have significant differences in performance, processing methods and application scenarios, so they play different roles in different industrial fields.

There are many types of aluminum alloys. They can divide into many types according to different classification standards. The following are several common types of aluminum alloys:

- Al-Cu alloys: contain copper, have good strength and corrosion resistance.

- Al-Si alloys: contain silicon, usually used for casting alloys.

- Al-Mg alloys: contain magnesium, have high corrosion resistance and welding performance.

- Al-Zn alloys: contain zinc, have excellent corrosion resistance and welding performance

Aluminum alloys types Classification by alloy elements

Aluminum alloys are usually classified according to their main alloying elements. Common alloying elements include copper (Cu), magnesium (Mg), silicon (Si), manganese (Mn), zinc (Zn), etc. The addition of these elements will significantly change the properties of aluminum alloys, such as strength, corrosion resistance, machinability, etc.

Al-Cu alloy (2xxx series)

Al-Cu alloy (2xxx series) with copper as the main alloying element, it has good heat treatment performance and is often used in fields with high strength requirements such as aerospace and automobiles.

Al-Mg alloy (5xxx series)

Al-Mg alloy (5xxx series) with magnesium as the main alloying element, it has good corrosion resistance and welding performance and is widely used in construction, shipbuilding and automobile industries.

Al-Si alloy (4xxx series)

Al-Si alloy (4xxx series) with silicon as the main alloying element, it has good casting performance and wear resistance and is often used in casting and machining.

Al-Mn alloy (3xxx series)

Al-Mn alloy (3xxx series) with manganese as the main alloying element, it has good corrosion resistance and processing performance and is suitable for general industrial use.

Al-Mg-Si alloy (6xxx series)

Al-Mg-Si alloy (6xxx series) with magnesium and silicon as the main alloying elements, it has good heat treatment performance and weldability and is widely used in construction and transportation industries.

Al-Zn-Mg alloy (7xxx series)

Al-Zn-Mg alloy (7xxx series) with zinc and magnesium as the main alloying elements, it has extremely high strength and good heat treatment performance and is suitable for aerospace and high-performance structural parts.

Other alloys (8xxx series)

Other alloys (8xxx series) include aluminum alloys containing other alloying elements (such as iron, titanium, etc.), usually for special purposes.

Classification by alloy state of Aluminum alloys types

Deformed aluminum alloys

Deformed aluminium alloys refer to aluminum alloys that can be formed by pressure processing (such as rolling, extrusion, forging, etc.). These alloys usually have high strength and good plasticity, and are suitable for structural parts that need to be formed by cold working or hot working. Deformed aluminum alloys can be further divided into two categories:

Non-heat-treatable alloys

This type of alloy cannot be heat treated to improve its strength, and mainly relies on cold processing (such as cold rolling and cold extrusion) to enhance its performance. Common non-heat-treatable aluminum alloys include:

- Aluminum-manganese alloy (Al-Mn)

- Aluminum-silicon alloy (Al-Si)

- Industrial pure aluminum (1xxx series)

- Rust-proof aluminum (LF series)

Heat-treatable alloys

This type of alloy can be significantly improved in strength and hardness by heat treatment (such as solution treatment, aging treatment). Common heat-treatable aluminum alloys include:

- Aluminum-copper alloy (Al-Cu)

- Aluminum-magnesium alloy (Al-Mg)

- Aluminum-zinc alloy (Al-Zn)

- Duraluminum (LY series)

- Superduraluminum (LC series)

- Forged aluminum (LD series)

Cast aluminum alloys (Cast Alloys)

Cast aluminum alloys refer to alloys that are formed into castings by pouring molten aluminum alloy into a mold and cooling it. Such alloys are usually used to make parts with complex shapes, such as engine blocks, gearboxes, etc.

Haichen produce cast aluminium alloys molds. The die-casting molds components mainly include: a fixed mold and a moving mold, a cavity, core, inserts, and a gating system. It also with an overflow and venting system. For some complex strucutre Like alulminum alloys cookware handle with chamfer. Haichen design it a with slider die casting mould. It need has an ejection system, including ejector pins, return pins, ejector plates, and ejector plate guide pillars/sleeves. It used to eject the solidified casting from the mold after mold closing.

Cast aluminum alloys have relatively low strength, but have good fluidity and are suitable for casting processes. Common cast aluminum alloys include:

- Aluminum-silicon alloy (Al-Si)

- Aluminum-copper alloy (Al-Cu)

- Aluminum-magnesium alloy (Al-Mg)

- Aluminum-zinc alloy (Al-Zn)

Classification by application field

Wrought aluminum alloys

Wrought aluminum alloys refer to aluminum alloys formed by cold working, hot working or mechanical working (such as rolling, extrusion, forging, etc.). These alloys have good plasticity and machinability and are suitable for parts that require high strength and good formability. Wrought aluminum alloys can generally be further divided into non-heat treatment strengthening type and heat treatment strengthening type.

Aluminum alloys for automobiles

such as 2xxx series, 5xxx series, and 6xxx series. These alloys are widely used in automobile body panels due to their light weight and high strength.

Aluminum alloys for construction

Aluminum alloys for construction: such as 6063-T6, 6070-T5, etc. These alloys have good processing performance and corrosion resistance.

Aluminum alloy for ships

Aluminum alloy for ships: high strength and corrosion resistance, suitable for shipbuilding.

Cast aluminum alloys

Cast aluminum alloys (Cast Alloys) Cast aluminum alloys refer to aluminum alloys formed by casting process. They are characterized by low melting point and suitable for manufacturing complex shapes, but poor plasticity and unsuitable for cold processing.

Automobile

Automobile: used to manufacture engine cylinders, pistons, wheels, etc.

Aerospace

Aerospace: used to manufacture engine parts, aircraft structural parts, etc.

Architecture

Architecture: used to manufacture doors, windows, roofs, curtain walls, etc.

Electronics

Electronics: used to manufacture radiators, wires, electronic housings, etc.

Classification by special properties

Heat-resistant aluminum alloy

Heat-resistant aluminum alloy: such as heat-resistant aluminum alloy used for power transmission lines.

Functionally gradient aluminum alloy

Functionally gradient aluminum alloy: different mechanical properties are achieved by changing the alloy composition and porosity.

Therefore, the above are some of the main classification methods of aluminum alloys, each of which has its specific application areas and performance characteristics. These aluminum alloys play an important role in modern industry and meet the material needs of different fields.

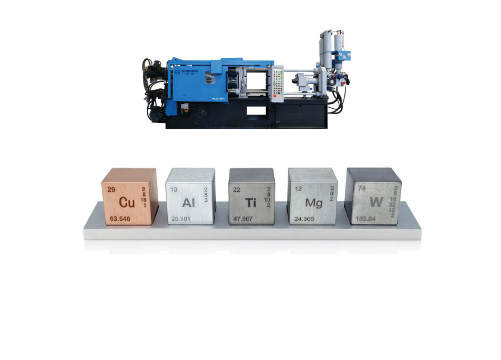

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.