Die casting mold installation precautions includes mold preheating, lubrication treatment, locking force selection and optimization of cooling system and others.

Precautions for Die Casting Mold Installation outline the essential safety and precision procedures that must be followed when placing molds into die casting machines. This document details critical operational steps, including preparatory work, alignment, and installation procedures, while explaining final inspection protocols.

Following the correct precautions of die casting mold installation is non-negotiable for safe and productive die casting. It requires careful preparation, precise alignment, and methodical final checks. Each step, from cleaning to torqueing bolts, impacts mold life and part quality.

During the installation of the die casting mold, please note the following precautions:

- Mold preheating

- Lubrication treatment

- Selection of mold locking force

- Optimization of cooling system

- Selection of mold materials

- Rationality of mold design

- Operating specifications

- Maintenance and inspection

Mold preheating

- Aluminum/Magnesium Alloy Molds

- Zinc alloy molds

- Temperature Uniformity

- Preheating Methods

- Preheat Time and Holding

Die casting molds need preheate before using. That to ensure that the mold surface temperature is close to the temperature of the molten metal.

Generally, the preheating temperature of the mold should be about 50-60°C higher than the temperature of the molten metal. It can reduce thermal shock and avoid cracks or deformation of the mold due to excessive temperature difference.

Aluminum/Magnesium Alloy Molds

- Aluminium/magnesium die casting mold preheat temperature should be controlled between 180°C and 320°C, depending on the alloy type and mold structure.

- The recommended temperature for aluminum-magnesium alloy molds is 250–320°C.

- (H13 mold steel) 150–280°C is recommended, and for complex, thin-walled parts, the temperature can be increased to 200–250°C.

Zinc alloy molds

Zinc alloy molds require a lower temperature, approximately 150–200°C.

Temperature Uniformity

Preheating should ensure uniform temperature across the mold to avoid overheating or underheating in certain areas.

Preheating Methods

- Mold temperature controller: The best choice, providing precise temperature control and ensuring uniformity.

- Flame gun/liquefied gas heating: Suitable for complex molds, but avoid directly burning thin-walled areas.

- Slow injection preheating: Simple molds can be preheated by injecting molten metal at a low speed.

Preheat Time and Holding

- Time Control: Preheating should be done gradually, avoiding rapid heating.

- For example: It takes approximately 10 minutes for the mold temperature controller to increase from room temperature to 100°C, and 10 minutes from 100°C to 200°C.

- Hot Holding Requirements: After reaching the target temperature, hold for ≥0.5 hours to stabilize the internal mold temperature.

Lubrication treatment

- Lubricant Selection Requirements

- Lubrication Practices

- Spray a thin, even layer

- Key Lubrication Areas

It is common practice to apply lubricants in the mold cavity, such as Turaes-S release agent, to prevent molten metal from adhering to the mold surface.

In addition, aluminum foil can be placed at the bottom of the mold cavity to further prevent the flow of the melt from being restricted.

Lubricant Selection Requirements

- Preferably use water-soluble lubricants to avoid the fire risk associated with oil-based lubricants. Water-soluble lubricants disperse evenly, withstand high temperatures and pressures, and form a protective release film.

- Safety and Environmental Protection: They must be non-toxic, produce no toxic gases, and avoid corrosion of mold steel.

Lubrication Practices

Clean the mold before spraying: Thoroughly remove any remaining metal chips, oil, and other impurities to prevent contamination of the lubricant.

Spray a thin, even layer

- Apply a small, even amount of spray each time, forming a thin film on the cavity surface.

- Avoid overspraying (which can lead to defects such as loose castings, slag inclusions, and air holes).

- Use a fine atomization spray gun to ensure even coverage.

Key Lubrication Areas

- Cavity surface (to facilitate demolding).

- All sliding/guide components (such as ejector mechanisms and movable blocks).

- Moving contact surfaces of the press (to reduce friction losses).

Optimization of cooling system

- Plan water channel locations rationally

- Optimize water channel structure

- Avoiding condensation and structural interference

The design of cooling system is crucial to mold life and product quality. A reasonable cooling system can effectively control mold temperature, reduce the occurrence of thermal fatigue cracks, and improve the surface quality and dimensional accuracy of castings.

Plan water channel locations rationally

Cooling channels should be located as close to the mold cavity surface as possible to avoid local overheating or insufficient cooling, ensuring uniform temperature distribution across the mold.

Optimize water channel structure

Topology optimization technology can replace traditional circular cooling channels. By designing cooling structures using discrete and Gaussian boundary conditions, thermal efficiency can be significantly improved:

- Reducing temperature gradients and shrinkage defects (e.g., reducing porosity by 43%).

- Supporting air instead of coolant eliminates scaling issues and improves sustainability.

- Adding a support base to secure the cooling structure prevents mold bending and deformation caused by high die-casting pressure.

Avoiding condensation and structural interference

- The cooling water temperature must be above room temperature to prevent condensation on the mold cavity surface.

- Water channel gaskets must be made of corrosion-resistant materials to ensure a tight seal.

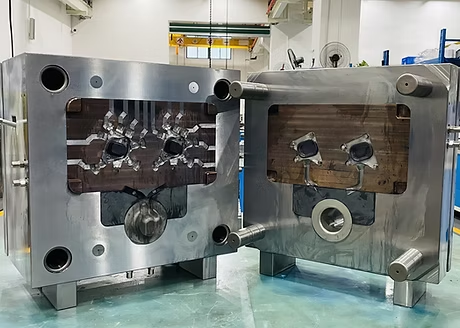

Selection of mold materials

- Matching Working Conditions

- Comprehensive Performance Requirements

The use of high temperature resistant and wear resistant materials (such as cemented carbide or nano-composite copper powder materials).

It can significantly improve the service life and wear resistance of the mold.

Matching Working Conditions

- Materials must meet high-temperature and high-pressure operating conditions: Die-casting molds must withstand the cyclic thermal shock of molten metal (e.g., aluminum alloys, approximately 660°C).

- Therefore, alloy steels with strong thermal fatigue resistance and high-temperature strength (e.g., H13, SKD61, 3Cr2W8V) should be selected.

- Avoiding Material Affinity: Select materials with low affinity for the casting metal (e.g., chromium-containing alloy steels) to prevent molten metal from sticking to the mold and accelerating wear.

Comprehensive Performance Requirements

- Wear Resistance: The cavity surface requires high hardness (HRC 45-50 recommended) to resist the friction caused by aluminum alloy flow. Hardness is the determining factor in wear resistance.

- Toughness: Resists impact fracture, especially for large molds or complex structures.

- Thermal Conductivity: Rapid heat dissipation reduces thermal stress and extends mold life.

- Processing Performance: This includes machinability, polishability (surface roughness Ra ≤ 0.1μm), and heat treatment stability.

Rationality of mold design

- Wall Thickness Uniformity

- Corner Fillets and Chamfers

- Draft Angle

Mold design should take into account deep cavity, complex shape and high precision requirements.

For example, when designing deep hole die casting molds, require a single hydraulic drawing structure and edge positioning method. Thus to ensure the accuracy of deep hole size and position.

Wall Thickness Uniformity

The design must ensure uniform wall thickness of the casting to avoid areas of excessive thickness. That could lead to uneven cooling, shrinkage cavities, or thermal stress concentrations. Thereby reducing the risk of mold deformation and cracking. Process holes should be provided in areas of uneven wall thickness.

Corner Fillets and Chamfers

- All external corners must be rounded or chamfered to avoid sharp edges that could lead to mold stress concentration and cracking.

- Corners of the casting must have a sufficiently large casting radius (R) to prevent sharp corners in the corresponding area of the mold, which could cause cracking.

Draft Angle

A reasonable draft angle must be set to ensure smooth demolding of the casting and minimize wear on the mold surface.

Operating specifications

- Personal Protective Equipment

- Environmental Safety

During the die casting process, the operating procedures should be strictly followed. Including the reasonable setting of parameters such as pouring temperature, pressure and speed.

For example, the pouring temperature usually sets above 180°C. And the mold preheating temperature needs to be higher than 180°C.

Personal Protective Equipment

- Operators must wear safety shoes, gloves, goggles (with side protection), and arm guards to prevent metal splash.

- Install protective shields at the mold parting surface contact points. Prohibit personnel from standing to the side of the parting surface to prevent molten metal from splashing.

Environmental Safety

- Open flames are strictly prohibited near the oil tank. If the oil temperature exceeds the specified limit, immediately cool it with water.

- In the event of a hydraulic oil leak, shut down the machine and disconnect the power supply immediately. If there is a risk of fire, release the nitrogen in the accumulator.

Maintenance and inspection

- Pre-Installation Inspection

- Installation and Commissioning Specifications

Regularly check the wear of the mold and replace damaged parts in time. In addition, the use of new materials such as ceramic coating can further protect the mold surface and extend its service life.

Through the above measures, the installation quality and service life of the die-casting mold can be effectively improved. While ensuring the high quality and production efficiency of the castings.

Pre-Installation Inspection

- Bolts and Fasteners: Thoroughly inspect all fastening bolts before installation to ensure they are fully tightened to prevent loosening during operation and accidents.

- Mold Alignment and Loading; The mold should be installed centered on the mold plate.

- Off-centering will result in uneven load distribution and accelerated wear on the toggle joint (this should be considered during the design phase).

Installation and Commissioning Specifications

- During installation/removal, the control knob must be in “Manual” mode.

- The debugging action should be slow and gradual to avoid large movements that may damage the mold.

HAICHEN’s Support for Ensuring Proper Installation

HAICHEN provides tools and services that simplify the precautions of die casting mold installation.

- Solve a Chronic Alignment Issue for one customer

- HAICHEN’s Machine Features for Easier Installation

Solve a Chronic Alignment Issue for one customer

One of Haichen cutomers spent hours aligning molds on their old machine, often resulting in flash on parts. HAICHEN service technicians found the machine’s platen parallelism was out of specification. We corrected this on their HAICHEN machine. Furthermore, we trained their team to use the machine’s built-in hydraulic mold clamps and digital position readouts. These features made alignment fast and visual. Now, their mold setup time is reduced by 60%, and flash defects are eliminated.

HAICHEN’s Machine Features for Easier Installation

Our machines include user-friendly features that address common installation challenges. Precision-machined platens ensure a flat mounting surface. Optional hydraulic clamping systems replace manual bolts, saving time and ensuring even force. Clear digital displays help operators center the mold accurately. We design our machines to make the precautions of die casting mold installation easier to follow.