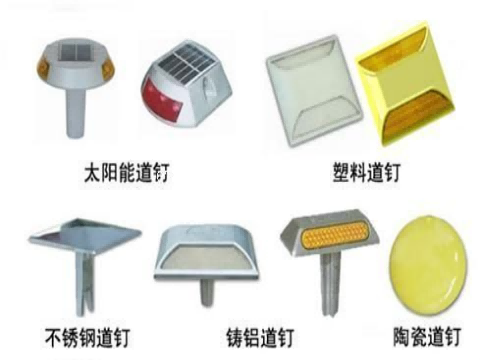

Aluminum road studs are made of high-strength impact-resistant aluminum alloy, with frosted glass or reflective strips on the surface, which can effectively reflect vehicle lights and significantly improve nighttime road visibility.

This type of road stud is suitable for highways, main roads and secondary roads, and has the following characteristics:

Strong pressure resistance

Excellent reflective performance

Long service life

Resistant to severe weather such as rain, snow, sandstorms, etc.

Die casting is the main process for the production of aluminum alloy parts, and its core equipment is the die casting machine and mold.

Aluminum Road Studs have a variety of features including night visibility and improved road demarcation.

This makes them important in road safety and traffic management.

Strong performance of die-cast aluminum alloy road studs

Some of the key features of aluminium road studs listing below:

- Enhanced night visibility

- Improved lane demarcation

- Durability and strength

- Reflective properties

- Aesthetics

- Multifunctionality

- Environmental adaptability

- Installation flexibility

Enhance night visibility

Aluminium reflective road studs can significantly improve the visibility of the road at night.

By reflecting the light from vehicle headlights, these spikes make the road ahead clearly visible.

This helps drivers to drive safely and reduces the risk of accidents.

Improve lane demarcation

Aluminium road studs are commonly to divide lanes and guide drivers, especially in areas such as complex road layouts, intersections or motorway exits.

This helps to improve lane discipline and reduce lane departure accidents.

Durability and strength:

Aluminium road studs are more durable and stronger than plastic road studs.

They are usually used for long term road works or permanent road separations and can withstand the weight of heavy trucks.

And they have good compression resistance.

Reflective properties

Aluminium road studs are fitted with reflective objects inside, which are usually made of reflective pigments.

They can effectively reflect light, thus improving visibility at night and in bad weather conditions.

Aesthetics

Aluminium road studs are not only powerful, they are also aesthetically pleasing, lighting up roads and beautifying urban environments.

Aluminium heavy duty road studs can withstand over 30 tonnes and their bright colours and diamond-like sparkle make them very popular in cities.

Versatility

Besides being as reflective signs, aluminium road studs can also be as speed bumps.

Especially on motorways or roads where heavy vehicles travel frequently.

This design can effectively slow down vehicles and improve road safety.

Environmental adaptability

Aluminium road studs have good weather resistance and corrosion resistance, and can maintain stable performance under various climatic conditions.

For example, some aluminium solar spikes can automatically turn on the blinking function in low-light conditions and are waterproof.

Installation flexibility

Aluminium road studs can be making in size and colour to suit different road requirements.

They can be installed in the centre or on both sides of the road and screwed into the ground.

Aluminium road studs play an integral role in modern road safety thanks to their excellent visibility, durability, aesthetics and versatility.

Production Features of aluminium road studs

The production characteristics of aluminium road nails mainly include material selection, manufacturing process and other aspects:

- Material selection

- Manufacturing process

- Reflective properties

- Bearing capacity

- Durability and life

- Installation and maintenance

Material selection:

Aluminium road studs are usually made from aluminium alloys such as AA alloy 1100, 5086, 5356 and 6061.

These materials have good compressive strength and corrosion resistance, enabling them to withstand heavy loads and adverse weather conditions.

Manufacturing process:

Aluminium road studs can be made by casting or welding process.

The casting process produces fully cast aluminium road studs with high compressive strength, while the welding process is used to weld aluminium studs to steel plates.

In addition, the casting process allows for the embedding of reflective material directly into the aluminium shell to enhance its reflective properties.

Reflective properties:

Aluminium road studs are usually equipping with reflective sheets or mirrors.

These reflective components can be single or double-sided reflective to enhance visibility at night or under adverse weather conditions.

The reflectors are usually made of imported materials and are fixed to the aluminium shell by epoxy resin to ensure their stability.

Load-bearing capacity:

Aluminium road spikes have a high load bearing capacity.

For example, some models can withstand more than 40 tonnes of weight and have waterproof performance, such as IP68 rating.

This high load carrying capacity and water resistance makes them suitable for use in a variety of road environments, including motorways and urban roads.

Durability and longevity

Aluminium road studs are favoured for their high strength and durability, with a typical lifespan of three to five years.

In addition, aluminium spikes are not easily damaged during use, making them suitable for long-term road construction and heavy vehicles.

Installation and maintenance

The installation of aluminium road studs usually needs to follow the manufacturer’s requirements to ensure their stability and safety.

In practice, aluminium spikes are often used in conjunction with painted markings to improve road safety and visibility.

Aluminium road studs are widely used in the field of road safety due to their high strength, corrosion resistance, high load capacity and long life.

These characteristics make aluminium road studs an effective tool for improving road safety and visibility.

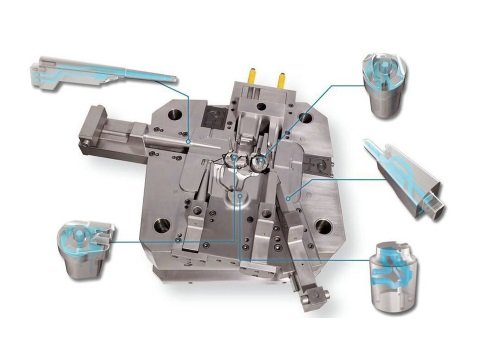

Aluminum Road Studs die casting machine features

Features of the Haichen aluminium road marker die casting machine include:

- High precision and complex shapes

- High strength and weight ratio

- High mechanical properties

- High dimensional tolerances

- Less impurities and low porosity

- High production efficiency

High precision and complex shape

Aluminium die casting machines are able to produce parts with high precision and complex shapes.

This is due to the application of CAD technology, which makes the design more detailed and meets the industry standard.

High strength and weight ratio

Aluminium die casting can produce lightweight but strong parts with a good strength to weight ratio.

This gives it an advantage over other metal casting methods.

High mechanical properties

Aluminium die castings have excellent mechanical properties such as hardness, strength and durability.

This is because the liquid metal solidifies under high pressure to form a fine, dense and crystalline structure.

High dimensional tolerances

Aluminium die castings usually have very high dimensional accuracy, which makes them perform well in service.

Few impurities and low porosity

The aluminium die casting process has low impurities and porosity in the metal parts as molten aluminium is injected under high pressure.

High production efficiency

Haichen aluminium die casting technology enables rapid production of parts.

Which usually does not require subsequent machining, thus increasing production efficiency.

These features make Haichen Aluminum Road Studs marking stakes die casting machines widely used in modern manufacturing.