Application of cooling chiller in die casting can control mold temperature, improve product quality, extend mold life and optimize production efficiency.

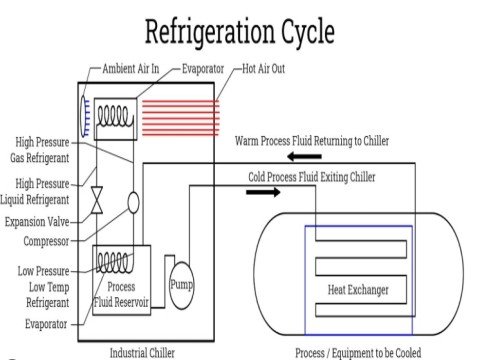

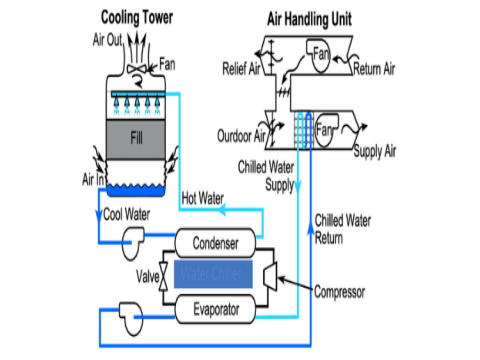

A chiller is a mechanical device, it uses for refrigeration. Its main function is to remove heat from a system through a refrigeration cycle and discharge it to the external environment. Chillers widely use in commercial buildings. Also in industrial facilities, data centers and other places. That to provide cooling water for air conditioning systems to regulate indoor temperature and humidity.

In the die casting process, the design and application of the cooling system is of great significance to improving product quality, extending the life of the mold and improving production efficiency. The cooling system usually controls the mold temperature through water cooling or other cooling media to achieve fast and uniform cooling effect.

The role of the cooling chiller in die casting application

The cooling system reduces casting defects (such as pores, shrinkage and deformation) by lowering the mold temperature to achieve rapid solidification of the molten metal, thereby improving the mechanical properties and surface quality of the casting.

In addition, the cooling system can extend the life of the mold and reduce thermal fatigue and wear caused by high temperature.

Uniform cooling and defect prevention

The cooler absorbs heat from the mold through a circulating cooling medium (water, oil, etc.), ensuring uniform solidification of the molten metal within the mold cavity. This reduces defects such as casting deformation, porosity, and cracks caused by uneven temperatures. Furthermore, insufficient cooling can lead to reduced casting dimensional accuracy and internal defects (such as shrinkage).

Improving surface quality

Precise temperature control improves the surface finish of castings, meeting higher industry standards.

Shortened Cycle Time

Rapid cooling accelerates metal solidification, thereby reducing production time per piece. Both [the authors] and [the authors] noted that the cooling system can significantly reduce cycle time and increase productivity.

Additionally, external water spray cooling can further accelerate mold cooling.

Ensuring Continuous Production

The authors] noted that uncontrolled mold temperature can cause localized overheating, leading to a decrease in mold steel strength (similar to a tempering effect). Cooling machines can avoid such downtime for maintenance.

Reducing thermal fatigue

During the die-casting process, molds are repeatedly subjected to high temperatures (molten metal temperatures can reach over 700°C). He and others emphasize that cooling systems regulate mold temperature, reducing thermal stress accumulation and thus delaying mold cracking and failure.

Preventing overheating damage

Warning: Localized overheating in the mold can cause material annealing, while cooling systems can even out the overall temperature distribution.

Classification of cooling chiller die casting methods

Common cooling methods include water cooling, oil cooling and air cooling:

Water cooling

Heat is removed by circulating water flow. It is suitable for occasions requiring uniform cooling. This method is efficient. But it requires regular maintenance to prevent leakage or blockage.

Oil cooling

High-temperature oil (200-300°C) uses to cool the mold. It is suitable for occasions requiring high thermal stability, such as magnesium alloy die casting. However, oil cooling may cause fire risks and is more complicated to maintain.

Air cooling

Relying on air or ambient air for cooling. It is low-cost but less efficient. And it usually uses for small or low-volume production.

Advantages of Cooling chiller in die casting application

- Improve production efficiency

- Extend mold life

- Improve product quality

- Optimize surface quality

- Improve production efficiency: Rapid cooling can shorten the cycle time of the mold, thereby increasing production speed.

- Extend mold life: By reducing the thermal stress caused by high temperature in the mold, the mold wear is reduced and the service life is extended.

- Improve product quality: Uniform cooling helps to reduce casting defects such as pores, cracks and deformation, and improve the overall strength and durability of the casting.

- Optimize surface quality: Precise temperature control can improve the surface finish of the casting and meet higher industry standards.

Improved Product Quality

Reduced Defects: Uniform cooling prevents casting deformation, porosity, and cracks, improving structural density and surface finish.

Dimensional Accuracy: Stable temperature ensures castings maintain tight tolerances (±0.1mm), reducing the need for subsequent machining.

Optimized Surface Quality: Conformal cooling reduces the need for spray lubricants and avoids surface ripples caused by uneven lubrication.

Extend mold life

Reducing Thermal Stress and Fatigue: Molds are prone to thermal stress during high-pressure, high-temperature cycles, leading to thermal fatigue cracks. The cooling system reduces thermal stress by controlling mold temperature and minimizing temperature gradients.

Preventing High-Temperature Damage: High temperatures accelerate mold material degradation. Mold steel has limited tolerance to high temperatures, and sustained high temperatures can easily lead to surface cracks.

Reducing Thermal Shock: Rapid temperature changes (such as pouring molten metal into a cold mold) can cause thermal shock cracks.

Optimize surface quality

Suppress shrinkage porosity and deformation: The cooling system ensures rapid and uniform solidification of the molten metal, avoiding shrinkage porosity, warping, or cracks caused by localized uneven cooling, thereby improving surface integrity.

Reduce surface waviness: Conventional spray cooling is prone to interfacial contamination due to lubricant accumulation, resulting in surface waviness (such as the “orange peel” effect). High-efficiency cooling (such as conformal cooling) reduces the need for spraying and directly improves surface finish.

Design and optimization of cooling system

The design of cooling system needs to consider the geometry, material properties and production requirements of the mold. For example, the use of conformal cooling technology can significantly improve cooling efficiency and shorten curing time.

In addition, by optimizing the layout of cooling channels through CAE analysis, the uniform distribution of mold temperature can be achieved, thereby improving product quality.

Position Optimization

The distance of the channel from the cavity surface directly affects thermal stress. For example, adjusting the channel from 16mm to 20mm can significantly reduce stress peaks

High-stress areas (such as those near the gate) should be avoided, and the position should be optimized using finite element analysis (such as ANSYS).

Uniformity Requirements

The channel should cover the entire cavity surface to avoid localized overheating.

Surface Smoothness

The smoothness of the channel inner wall affects cooling efficiency and corrosion resistance.

Maintenance and management of cooling system

The normal operation of the cooling system requires regular maintenance, including checking the sealing of the cooling pipes, cleaning the coolant and calibrating the temperature control system. In addition, the use of intelligent monitoring technology can monitor the mold temperature in real time to ensure the stability and reliability of the production process.

Temperature Control and Casting Quality

- The cooling system regulates temperature through cooling channels (water, oil, or air) within the mold, ensuring uniform solidification of the molten metal and minimizing defects such as porosity, shrinkage, and deformation.

- Precise temperature control can shorten production cycles. For example, conformal cooling technology, using 3D-printed channels, can improve cooling efficiency by 20-30%.

Key Design Elements

- The channel layout must cover mold “hot spots” (such as thick wall areas) to prevent local overheating.

- Select a cooling method based on the alloy type: Aluminum alloys are suitable for water cooling (efficient and low-cost), while magnesium alloys require oil cooling (high-temperature resistance up to 300°C).

Extending mold life

- Insufficient cooling can lead to thermal stress accumulation in the mold, causing cracks (thermal fatigue).

It is important to avoid shock cooling. - The recommended cooling water temperature is ≥ 20°C (optimally 50°C) and maintained stable using a constant temperature system.

- Mold surface treatment (such as nitriding) can improve heat resistance.

Innovation and development of cooling technology

In recent years, additive manufacturing technologies (such as SLM) have been used to design complex cooling channels. Furtherly, it can improve cooling efficiency and mold life.

In addition, the application of composite cooling irons has also shown potential in reducing defects and improving production efficiency.

Improved Product Quality

Uniform cooling reduces casting defects (such as pores, cracks, and deformation), improves microstructure, and enhances mechanical properties (tensile strength, ductility), as well as surface finish.

The chilling effect of the metal mold refines the grain size, resulting in significantly better performance for die-cast parts than sand castings.

Extended Mold Life

By controlling the mold temperature (typically maintained at 300–400°C), thermal stress and fatigue are reduced, overheating damage to the mold is avoided, and maintenance costs are lowered.

Improved Production Efficiency

Cooling systems shorten casting solidification times (e.g., through water cooling, air cooling, or cooling fins), thereby reducing production cycle times and increasing productivity.

For example, spray cooling technology increases cooling rates by 82% compared to traditional channel cooling.

Energy Saving and Environmental Protection

High-efficiency cooling systems reduce energy consumption, minimize scrap, and align with sustainable development goals.

The impact of cooling systems on production efficiency

An effective cooling system can shorten the production cycle, improve mold utilization, and reduce scrap rates. For example, in aluminum die casting, by optimizing the cooling design, it can significantly increase the production speed. It can also reduce energy consumption.

The application of cooling system in die casting process not only directly affects product quality and production efficiency, but also has a profound impact on mold life and equipment maintenance. Therefore, when designing and implementing cooling scheme, it is necessary to comprehensively consider the selection of cooling method, optimization of system design and details of maintenance management to achieve efficient and stable production goals.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.