Application of sprayer is to lubricate die casting machine molds, control temperature, improve casting quality, realize spraying automation.

By precisely controlling the spraying operation, this equipment can significantly improve production efficiency and casting quality.

The sprayer (commonly referred to as the spraying system in the industry) is mainly use to evenly spray materials such as release agents onto the mold surface before die casting begins.

Below we will explain in detail the practical application of the sprayer in the die casting machine.

Core functions and technical principles of sprayers

- Basic definition and function

- Workflow

- Key component technical parameters

Basic definition and function

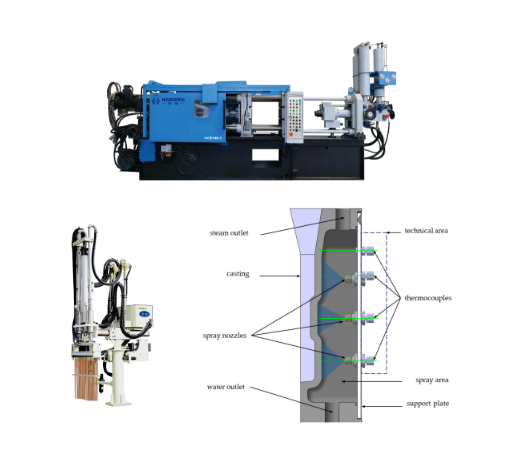

Die-casting sprayers are devices that use high-pressure pumps to atomize release agents/coolants and evenly spray them on the mold surface. The core functions include:

- Demolding lubrication: reduce adhesion between castings and molds, and reduce demolding damage

- Mold cooling: control the mold temperature field, prevent thermal deformation and shorten the molding cycle

- Surface cleaning: the air blowing system removes residual debris to ensure the cleanliness of the cavity

Workflow

| High-pressure pump pressurization | Atomizer mixes release agent and air | Nozzle sprays into the mold cavity | Compressed air blows away residual droplets | Robot resets |

Note: After the die-casting mold is opened, the robot drives the nozzle into the mold gap to complete the spray-blow-drying action simultaneously

Key component technical parameters

| Component | Parameter requirements | Injection molding correlation |

| Nozzle type | Fan (strong impact)/cone (uniform atomization) | Select the shape according to the fluidity of the plastic |

| Spraying pressure | 0.4-0.6 MPa | affects the surface finish |

| Atomized particle | size 20-100 μm | Particle size is too large to form water marks |

| Covering accuracy | ±20% uniformity | Avoid local mold sticking |

Application of sprayer for die casting machine

- Die Lubrication and Demolding

- Temperature Control

- Improved Quality

- Improved Production Efficiency

- Multi-cavity mold application

Die Lubrication and Demolding

In die casting production, the core function of the sprayer is to spray the mold surface with a release agent or lubricant. This operation can effectively reduce the friction between the molten metal and the mold, prevent the metal from sticking to the mold, and ensure the casting is smoothly demolded. At the same time, the release agent can also improve the molding quality of the casting surface and reduce the need for subsequent processing.

Temperature Control

The spray system can be used to add coolant to the mold surface, which is essential to maintaining the mold temperature. Stable temperature control not only ensures that the alloy forms the expected internal structure, but is also directly related to the overall quality of the casting.

Improved Quality

After evenly applying the release agent with a spray gun, the surface quality of the casting can be significantly improved – there are fewer problems such as pores and impurities, the dimensions are more accurate, and the product quality is more stable.

Improved Production Efficiency

Using a sprayer can effectively reduce equipment downtime and extend the service life of the mold by reducing mold wear. This is crucial to maintaining the stability of the casting process, especially in large-scale production, where a continuous and stable production process can significantly improve overall efficiency.

Multi-cavity mold application

During the die casting process of multi-cavity molds, the sprayer ensures that each mold cavity is evenly covered with release agent. This uniform spraying avoids product defects caused by coating differences and keeps all castings in the same batch of highly consistent quality.

Advantages of sprayer for Haichen die casting machine

- Precision spraying

- Durability

Precision spraying

Haichen Machinery’s sprayer uses an advance precision control system to ensure that the release agent is spraye evenly. And in the right amount on the mold, avoiding waste and improving the quality of castings.

Durability

At the same time, made of high-quality materials, Haichen Machinery‘s sprayer has excellent durability and corrosion resistance, extending the service life of the equipment.

The correct use of sprayers in die casting machines is essential to ensure the quality and efficiency of the casting process. By precisely controlling the application process, manufacturers can achieve efficient, economical and environmentally friendly production goals.