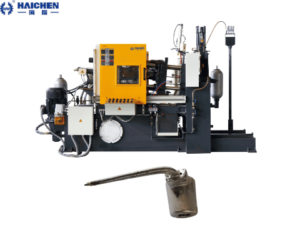

Types of ladle cup in die casting

In the die-casting process, “ladle cup” usually refers to the pouring cup (also called external gate). Its core function is to receive the molten metal from the ladle and guide

In the die-casting process, “ladle cup” usually refers to the pouring cup (also called external gate). Its core function is to receive the molten metal from the ladle and guide

Heating bush solutions for die casting machines requires a combination of structural design, material science, intelligent control and precision manufacturing technology. A heating bushing is a critical component used in

Die casting heating bush cost analysis includes material cost, mold cost, production cost, post-processing costs and so on. The die-casting cost of the heating sleeve will affect by many factors. Such

To select heating bush in die casting mainly includes material and application, evaluate the heating requirements, assess the durability and maintenance. Heating bush plays a critical role in die casting

The heating bush in die casting is primarily used for localized temperature control in molds. Its material selection and performance design must balance high-temperature stability, thermal conductivity efficiency, and durability.

Common troubleshooting for heating bush issues in die casting includes checking for electrical faults, ensuring proper lubrication, verifying thermal insulation, and inspecting for wear and tear to maintain optimal performance

Plunger Rings also known as the injection sleeve or pressure ring is one of the core components of the injection system of the die-casting machine. It mainly transmits pressure, seals

Die casting plunger ring application includes improve production efficiency and product quality, reduce defects, etc. The plunger ring used in the die casting process is an important part of the

Plunger rings play a critical role in the efficient operation of various mechanical systems, particularly in hydraulic and pneumatic applications. Plunger Rings Design Manufacturers produce them using advanced materials and

Plunger rings (also known as plunger tips or plunger heads) are critical components in die casting machines, responsible for sealing the shot sleeve and ensuring precise injection of molten metal into the mold.