Cooling methods in die casting are crucial for quality and efficiency, using water or air to control mold temperatures.

Die casting is a precision manufacturing process that involves injecting molten metal into a mold cavity under high pressure.

One of the critical aspects of this process is the cooling phase, where the molten metal solidifies to form the final product.

Effective cooling methods are essential for ensuring high – quality castings, dimensional accuracy, and efficient production.

This article will explore the different cooling methods used in die casting and their benefits.

Cooling Methods in Die Casting

- Water – Cooled Molds

- Air – Cooled Molds

- Spray Cooling

- Hybrid Cooling Systems

Water – Cooled Molds

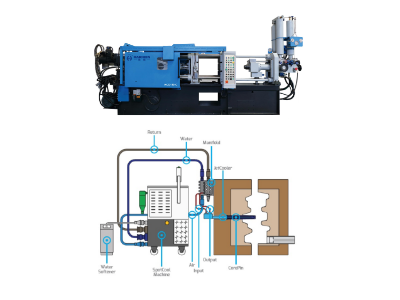

Water – cooled molds are one of the most common cooling methods in die casting. These molds are equipped with internal cooling channels through which water circulates. The water absorbs heat from the molten metal, allowing it to solidify quickly and uniformly. This method is highly effective in reducing cycle times and improving the surface quality of the castings.

Benefits:

- Rapid Cooling: Water – cooled molds provide rapid and consistent cooling, reducing the risk of defects such as warping and shrinkage.

- Uniform Solidification: The even distribution of cooling channels ensures that the molten metal solidifies uniformly, maintaining dimensional accuracy.

- Energy Efficiency: Water – cooled systems are generally more energy – efficient compared to other cooling methods.

Air – Cooled Molds

Air – cooled molds rely on the flow of air to dissipate heat from the molten metal. This method is often used in applications where water – cooled systems are not feasible or when a more controlled cooling rate is required.

Benefits:

- Controlled Cooling Rate: Air – cooled molds allow for a more controlled cooling rate, which can be beneficial for certain types of metals or complex geometries.

- Reduced Risk of Corrosion: Unlike water – cooled systems, air – cooled molds do not pose a risk of corrosion, making them suitable for certain materials.

- Flexibility: Air – cooled molds offer greater flexibility in mold design, as they do not require complex cooling channel systems.

Spray Cooling

Spray cooling involves spraying a fine mist of water or a water – based coolant onto the surface of the mold. This method provides rapid cooling and can be particularly effective for large or complex molds.

Benefits:

- Rapid Heat Transfer: Spray cooling offers rapid heat transfer, ensuring quick solidification of the molten metal.

- Surface Quality: The fine mist provides a uniform cooling effect, improving the surface quality of the castings.

- Customizable: Operators can customize spray cooling for specific mold areas to provide targeted cooling where needed.

Hybrid Cooling Systems

Hybrid cooling systems combine multiple cooling methods to optimize the cooling process. For example, a hybrid system might use water – cooled channels for rapid initial cooling, followed by air – cooled systems for controlled final cooling.

Benefits:

- Optimized Cooling: Hybrid systems provide the benefits of multiple cooling methods, ensuring optimal cooling for complex molds and materials.

- Flexibility: These systems offer greater flexibility in mold design and cooling strategy, allowing for customization to specific production needs.

- Efficiency: Hybrid cooling systems can improve overall production efficiency by reducing cycle times and improving part quality.

HAICHEN: Integrated Solutions with Smart Cooling Systems

In die casting cooling, HAICHEN provides more than machines. We offer system solutions based on deep process know-how. Our smart temperature control and mold cooling work together. This ensures efficient and even cooling for all parts, from thin-wall items to large structures. It stabilizes product quality and boosts production efficiency.

- Custom Cooling Circuit Design Support

- Integrated High-Precision Mold Temperature Control

- Case Study: Solving Warpage in an Auto Engine Bracket

Custom Cooling Circuit Design Support

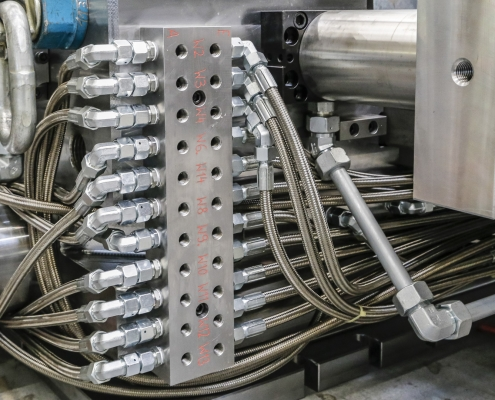

HAICHEN engineers can join mold cooling reviews early in a project. We look at the part shape, wall thickness changes, and hot spots. Then, we give advice to optimize the cooling channel layout. For example, for parts with thick bosses or ribs, we suggest using pinpoint cooling or baffled water channels. This targeted cooling reduces the risk of shrinkage holes.

Integrated High-Precision Mold Temperature Control

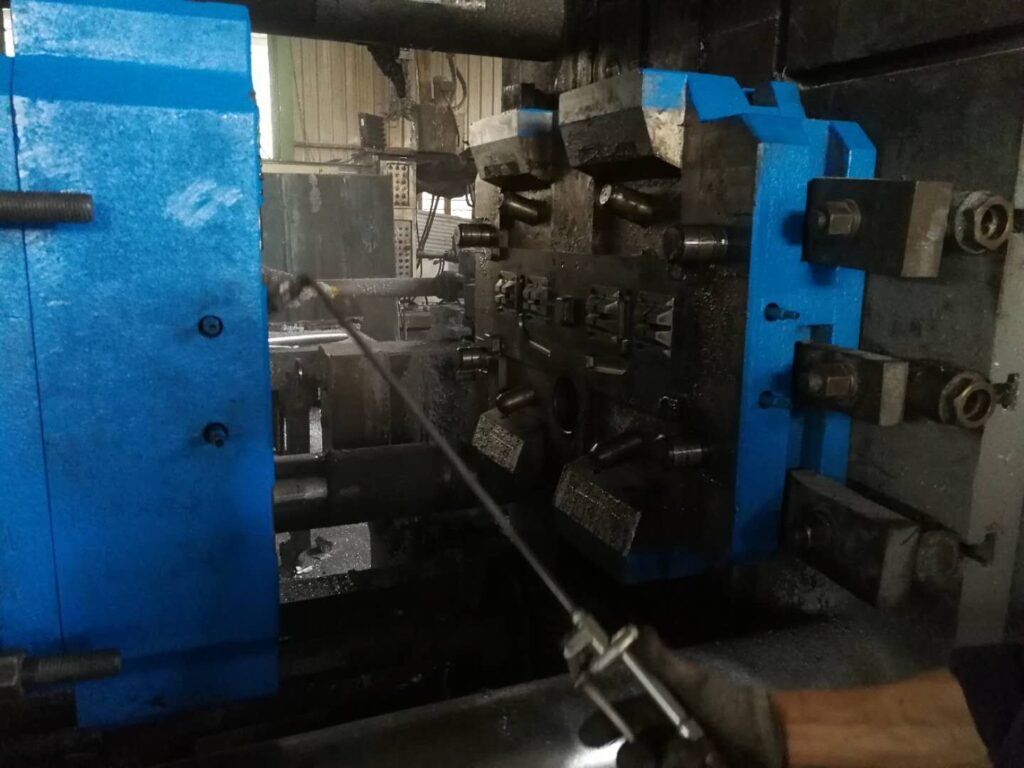

HAICHEN die casting machines come with multi-zone smart mold temperature controllers. They connect directly to the mold’s cooling channels. The system can control the temperature of different mold areas (like fixed side, moving side, cores) independently and with closed-loop accuracy of ±1°C. Keeping each zone at its set temperature ensures mold heat balance. This reduces part warpage or cracks caused by temperature differences.

Case Study: Solving Warpage in an Auto Engine Bracket

An auto parts maker had problems with an aluminum engine bracket. The flatness was out of spec, and distortion after heat treatment was not consistent.

- Problem Analysis: Our team found uneven mold cooling. The mold core forming the mounting face did not cool enough. This area solidified slower and shrank unevenly, causing the warpage.

- Solution:

- Cooling Upgrade: We redesigned the cooling channels in that core. We changed from a single loop to several parallel loops. This increased water flow and cooling area.

- Process Setup: On the HAICHEN 800T machine, we set the mold temperature controller differently. We used stronger cooling (~150°C) for the mounting face core area, and higher temperature (~180°C) for other areas. This guided solidification in a better order.

- Process Monitoring: We used the machine’s monitoring system to track key mold temperatures in real time, keeping the process stable.

- Result: The bracket’s flatness was controlled within 0.15mm. Distortion after heat treatment became much more consistent. The product yield rate rose from 92% to 98.5%. The production cycle time also shortened by about 8%.

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we specialize in manufacturing high – quality die casting machines equipped with advanced cooling systems. Our machines are designed to provide precise control over the cooling process, ensuring high – quality castings and efficient production. Whether you are starting a new project or upgrading your existing equipment, HAICHEN has the solutions to meet your needs.

Understanding and optimizing cooling methods in die casting is crucial for achieving high – quality castings and efficient production. By choosing the right cooling method or combination of methods, manufacturers can reduce cycle times, improve part quality, and maintain dimensional accuracy.