Die Casting Overflow design necessitates the management of flow dynamics, heat regulation, and ease of manufacture. Validate configurations with the help of modeling software, employ conventional forms, and involve foundries from the start for continuous improvement.

Well-designed overflow systems can decrease fault rates (such as porosity and cold shuts) by approximately 30% in high-pressure die casting.

Overflow wells are essential for achieving proper metal flow, lowering porosity levels, and reducing defect rates in die casting processes. The following key design principles have been extracted from expert sources:

Some key points about die casting flow

- Location Selection

- Shape & Dimensions

- Simulation & Validation

- Thermal Management

- Post-Processing & Cost

- Special Cases

Location Selection

- End-of-Fill Placement: Position overflows at the last areas to fill in the cavity (e.g., corners, thin walls, or complex geometries) to guide metal flow and trap oxides/gas.

- Integration with Venting: Connect overflows to venting channels (e.g., venting slots or vacuum systems) to ensure gas escapes the mold. Optimize overflow placement in high-pressure gas zones.

Shape & Dimensions

- Trapezoidal Cross-Section: Use a trapezoidal shape with:

- Width: 20–30 mm (not inches; corrected based on industry standards), Depth: 8–10 mm,

- Bottom radius: 2–3 mm, and a 15–20° slope per side to reduce flow resistance.

- Runner Connection:

- Depth: 0.6–1.5 mm (1.0 mm optimal for minimizing porosity).

- Width: 10–30 mm. Avoid excessive depth to prevent material waste.

- Volume Control: Overflow volume should account for 20–30% of the casting volume (higher for thin-wall parts) to trap cold/contaminated metal and balance mold temperature.

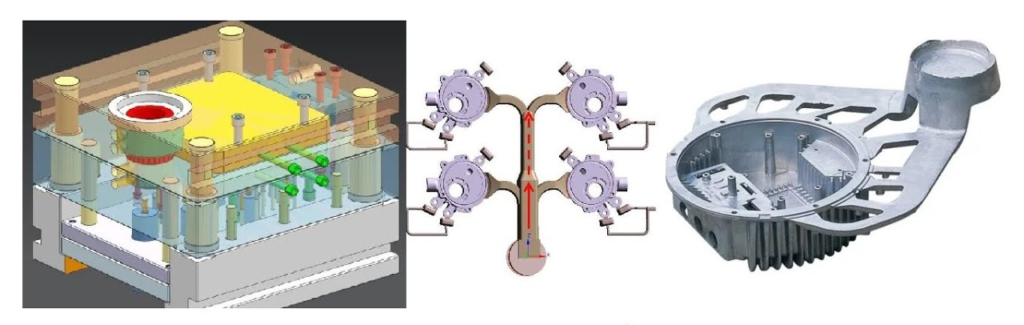

Simulation & Validation

- Flow Simulation: Use tools like Cast-Designer or MAGMASOFT® to simulate filling patterns, identify gas traps, and optimize overflow placement/size.

- Parametric Design: Leverage software to model standard overflow shapes (rectangular, circular, wedge) and adjust parameters (orientation, grouping) efficiently.

Thermal Management

- Temperature Uniformity: Coordinate overflows with cooling channels to maintain thermal balance. Add cooling near overheated overflow zones to prevent cold shuts.

- Reducing Turbulence: Avoid direct impingement of metal flow on cores/inserts. Use curved transitions or angled entries to minimize erosion.

Post-Processing & Cost

- Ease of Trimming: Design overflows along parting lines for easier removal and reduced flash.

- Material Efficiency: Avoid oversized overflows to lower material waste and cost while ensuring functionality.

Special Cases

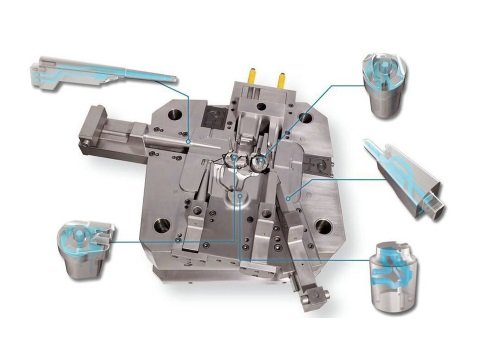

- Multi-Cavity Molds: Ensure consistent overflow dimensions and flow paths across all cavities for uniform filling.

- Vacuum-Assisted Casting: Integrate overflows tightly with vacuum systems for complex parts to enhance gas evacuation.

Hot chamber Die Casting Overflow Features

Hot chamber die casting is renowned for its efficiency, material compatibility, and high-quality output. The overflow system plays a critical role in optimizing process parameters and minimizing defects. Below is a detailed analysis:

- Rapid Filling & High-Pressure Dynamics

- Material Compatibility & Overflow Design

- High Productivity & Overflow Management

- Quality Enhancement & Porosity Control

- Process Limitations

Rapid Filling & High-Pressure Dynamics

- High-speed injection (0.3–140 m/s) and ultra-short fill time (0.02–0.3 seconds) enable molten metal to fill the cavity almost instantaneously.

- Final pressure reaches up to 500 MPa, creating a “water hammer effect” that forces metal against the mold surface, forming a dense outer layer (0.02–0.2 mm thick) with reduced surface porosity.

- Overflow function: Acts as a vent to expel entrapped gases and excess metal, preventing internal voids and flash defects.

Material Compatibility & Overflow Design

- Low-melting-point alloys (e.g., zinc, magnesium, lead alloys) are ideal for hot chamber die casting due to their fluidity.

- Overflow systems are crucial for managing gas entrapment during fast filling. For example, in ZAMAK 5 zinc alloys, optimized parameters like injection speed (4–5 m/s) and cooling time (0.8–2 seconds) are paired with well-designed overflows to control flow paths and gas venting.

High Productivity & Overflow Management

- Short cycle times (up to 15 cycles/minute) demand automated overflow and venting systems to remove residual gases and excess metal efficiently.

- Multiple overflow wells and vents are integrated into mold designs to ensure uniform filling and minimize post-casting trimming.

Quality Enhancement & Porosity Control

- Overflows collect cold metal fronts and gases, reducing internal porosity.

- Surface finish: High pressure and short mold contact time yield smooth surfaces (Ra 0.8–3.2 μm) and tight tolerances (±0.1 mm).

- Overflow design directly impacts mechanical strength and leak-tightness of castings.

Process Limitations

- Material constraints: Hot chamber die casting is unsuitable for high-melting-point alloys (e.g., aluminum).

- Turbulent flow risks: High-speed filling may cause localized turbulence, requiring simulation tools to optimize overflow placement and gas venting.

More need to know

Overflow design in hot chamber die casting is pivotal for balancing speed, pressure, and material behavior:

- Gas venting: Critical for avoiding porosity in rapid filling.

- Flow control: Directs metal to minimize turbulence.

- Material suitability: Overflow necessity varies with alloy fluidity (e.g., zinc vs. magnesium).

- Automation: Overflow systems must align with high-speed production demands.

This makes hot chamber die casting ideal for mass production of automotive components, electronics housings, and other high-volume parts, provided overflow systems are meticulously engineered for defect-free output.

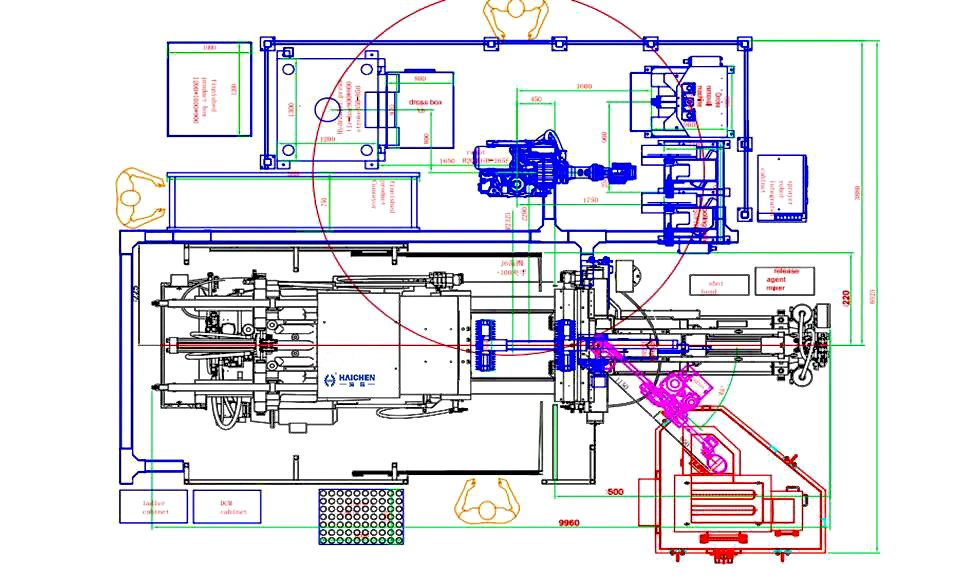

Haichen die casting machine Overflow design

Haichen’s overflow design is closely integrated with its injection control system and mold engineering, aiming to optimize molten metal flow, vent gases, and eliminate excess material to enhance casting quality. Below is an evidence-based technical breakdown.

- Injection Phase Control

- Mold & Structural Engineering

- Hydraulic & Control Systems

- Material Adaptability

- Smart Automation Integration

Injection Phase Control

Haichen’s C-series cold-chamber machines utilize four-stage injection control (slow speed, first fast speed, second fast speed, and intensification). Magnetic rulers and Siemens PLCs ensure precise injection positioning. This multi-phase control minimizes turbulence and gas entrapment, indirectly supporting overflow efficiency. For example, pressure sensors during the intensification phase stabilize cavity pressure, preventing underfilling or insufficient overflow activation.

Mold & Structural Engineering

Haichen’s machines comply with industry standards (e.g., JB/T8083-2000) and EU CE safety norms. Critical components are optimized via finite element analysis (FEA) for stress distribution. Dynamic/static platen parallelism is controlled within 0.12mm, ensuring mold sealing integrity—critical for overflow gate functionality. Extended mold-opening strokes (e.g., in C-series machines) also accommodate complex overflow channel layouts.

Hydraulic & Control Systems

High-precision hydraulic components (Vickers, Yuken) and industrial controllers guarantee stable injection speed/pressure. For instance, rapid injection accumulators and servo-valve technology enable high-speed filling while overflow vents expel cold metal and gases. Real-time injection curve displays allow operators to monitor overflow performance.

Material Adaptability

Cold-chamber machines are tailored for high-melting-point alloys (Al, Mg), where overflow design must handle viscous flow, while hot-chamber units target Zn/Pb alloys. Haichen’s shot sleeves incorporate alloy-specific cooling to match overflow requirements.

Smart Automation Integration

Multi-language controls and automation tools (auto-sprayers, pick-and-place robots) enable overflow monitoring and feedback loops. For example, centralized lubrication systems (maintained every 500-700 cycles) ensure smooth operation of overflow-related mold components.

Haichen’s overflow design systematically optimizes casting integrity through multi-phase injection, precision mold alignment, stable hydraulics, and smart automation. Haichen’s compliance with standards (e.g., JB/T8083), real-time pressure/position adjustments, and defect-reduction outcomes align with advanced overflow functionality. This approach reduces porosity and improves mechanical properties in castings.

Contact Haichen anytime for more die casting technical details.