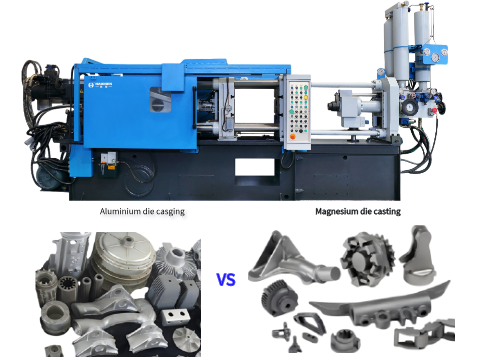

Die casting materials application are mainly including aluminum alloy, magnesium alloy and zinc alloy materials.

Alumnium alloy, magnesium alloy and zinc alloy die-casting are irreplaceable in the automotive, electronics, consumer goods, and emerging high-performance sectors, particularly suited to cost-sensitive applications with complex structures and high surface quality requirements. Material innovations (such as ACuZinc ) is continuously expanding its application boundaries.

These die casting materials are widely used due to their excellent mechanical properties, dimensional stability and surface quality. We will analyze common aluminium, magnesium and zinc alloy die casting material specific application as following:

- Aluminum alloy die casting material application

- Magnesium alloy application

- Zinc alloy die casting material application

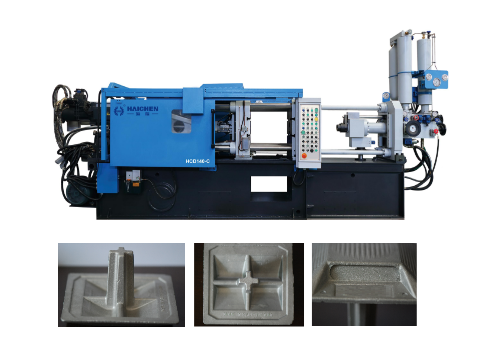

Aluminum alloy die casting material application

- Automotive Industry (Core Application Area)

- Electronics and Consumer Electronics Industry

- Aerospace

- Industrial Equipment and Infrastructure

Aluminum alloy is one of the most commonly used die casting materials. And its application is very wide, including automobiles, aluminium pot, electronic products, computer hardware and other fields.

Moreover, aluminum alloy die castings have high strength and good castability, suitable for the production of a large number of small to medium-sized parts.

Automotive Industry (Core Application Area)

Lightweight Components: Used in engine blocks, transmission housings, gearboxes, and structural parts, reducing weight to improve fuel efficiency and vehicle handling.

- Specific Alloy Applications:

- A380 Alloy: Engine blocks and transmission housings

- A360/A356 Alloys: Structural parts and engine covers

- A390 Alloy: Chassis and wheels

Braking System and Body Components: Such as door handles and brake system components, utilizing its high strength and heat dissipation properties.

Electronics and Consumer Electronics Industry

- Casings and Structural Components

Electronic product casings (such as mobile phones and computers), heat sinks, and connectors rely on its precision molding capabilities and electromagnetic shielding properties (RFI/EMI protection). - Specific Alloy Applications

A383 Alloy: Electronic Housings and Connectors (Excellent Dimensional Stability)

A380 Alloy: Structural Components for Consumer Electronics - Performance

Excellent conductivity, electromagnetic shielding, and surface treatment adaptability (electroplating and spray coating possible)

Aerospace

Lightweight Structural Parts

- Non-core high-temperature components such as engine/gearbox housings and brackets (limited by high-temperature performance).

- High-toughness alloys (such as A356) are used for high-precision structural parts.

Industrial Equipment and Infrastructure

- Mechanical Components:

Pneumatic tools and industrial machinery parts (such as valves and pump bodies). - Communications and Energy Equipment:

Communications base station components, network equipment housings, and new energy industry components (such as LED lampshades and radiators).

For example, to produce road reflective marker and road studs, Haichen use aluminum alloy die casting material because this materials have high strength and good castability. At the same time, match with Haichen high pressure aluminium alloy road stud die casting machine. It can reach max high output production.

Magnesium alloy application

- Automotive Industry (Leading Industry)

- Electronics and Home Appliances

- Aerospace and Transportation

Magnesium alloy is widely used in the aerospace and automotive industries due to their lightweight properties.

Furthermore, magnesium alloy die castings have good mechanical properties and excellent shock absorption characteristics. It manufactures in complex shapes within a short production cycle.

Automotive Industry (Leading Industry)

Lightweight Components: Magnesium alloys have a density only two-thirds that of aluminum and one-quarter that of steel.

Significantly reducing component weight (by 25%-75%), improving fuel economy and the range of new energy vehicles (a 10% weight reduction can increase range by 5%-8%).

Typical Components

- Structural components: Instrument panel crossbars (such as the 2005 Ford GT magnesium alloy crossbar), steering components, transmission housings, intake manifolds, oil pans, engine mounts, etc.

- Powertrain components: Gearbox housings, crankcases, oil pump housings, and other components requiring high-temperature performance.

- Battery Packs: Replacing aluminum alloy housings can reduce weight by nearly 50% (e.g., the Tesla Model S battery pack reduces weight by 60kg).

- Market Share: The automotive industry accounts for over 80% of magnesium alloy die-casting consumption. China plans to use 45kg per vehicle (4% of vehicle weight) by 2030.

Electronics and Home Appliances

- Thin and lightweight housings: Laptop computers, mobile phones, DVD cases, etc., utilizing their high specific strength, heat dissipation, and electromagnetic shielding properties.

- Process Advantages: Die casting can produce complex thin-walled parts (for example, DVD cases require controlled injection angle, flow rate, and other parameters).

Aerospace and Transportation

Aircraft parts, motorcycle wheels (for example, AM60B alloy wheels achieve vibration and noise reduction through liquid squeeze casting).

Zinc alloy die casting material application

- Automotive Industry

- Electronics and Electrical Fields

- Consumer Goods and Household Goods

- Industrial and General Machinery

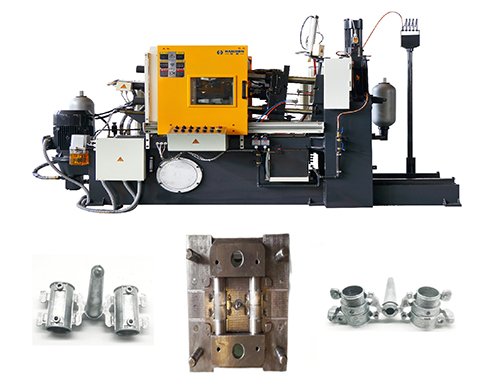

Zinc alloys is used to manufacture motors, mechanical parts, hand tools, toys, zinc medals, etc. due to their high fluidity and ability to produce very fine details and thin-walled structures.

In addition, zinc alloy die castings have a smooth surface and are suitable for electroplating and other surface treatments.

For examples, Haichen use zinc alloy die casting machine material to produce various type of zinc pipe fitting couplings. Because zinc alloy material with high fluidity.

Automotive Industry

Zinc alloy die-castings, due to their high strength, corrosion resistance, and dimensional stability, are widely used in:

- Key functional components: steering system components (such as steering column terminals), brake system parts, fuel system components, and engine peripheral parts.

- Lightweight and thin-wall design: Zinc alloy’s thin-wall casting capability (down to 0.5mm) meets automotive lightweighting requirements while maintaining structural strength.

Electronics and Electrical Fields

- Precision electronic components: Connectors, switches, terminals, etc. are widely used due to zinc alloy’s excellent conductivity, electromagnetic shielding properties, and dimensional accuracy.

- Corrosion Resistance Applications: Zinc alloy is resistant to electrochemical corrosion and is suitable for marine equipment and outdoor electronic components.

Consumer Goods and Household Goods

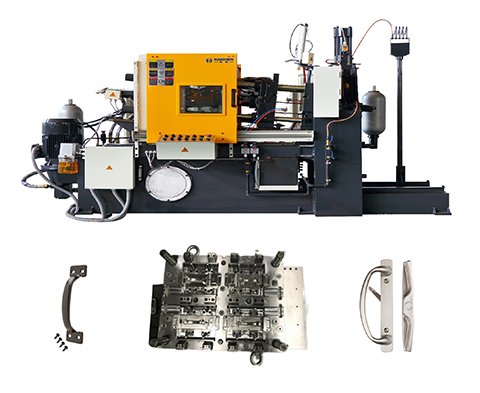

- Hardware and Household Goods: Locks, zippers, buckles, door handles, etc. benefit from zinc alloy’s easy electroplating, high surface finish, and low cost.

- Decorative components: Badges and decorative artwork take advantage of its excellent surface finish (as in the case of Neway).

- For instance, Like Haichen zinc alloy door handle production process , produce zinc alloy material match with Haichen hot chamber die casting machine, it can produce multipul cavities door handles.

Industrial and General Machinery

- Complex Structural Parts: Zinc alloy’s high fluidity enables the one-step molding of complex geometries (such as thin walls and fine textures), reducing the need for machining.

- Cost-Effective Alternative: In applications where lightweighting is not a primary concern (such as tools and machinery housings), zinc alloy offers lower costs than aluminum alloy.

Die casting materials application mainly include aluminum alloys, magnesium alloys, and zinc alloys die casting materials. They are the most common choices. The selection depends on the requirements of the specific application, including factors such as mechanical properties, dimensional accuracy, surface quality, and production efficiency.

Haichen die casting machine

aichen is one Chinese die casting machine manufacturer. We produces high pressure die casting machines. It includes cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features. Haichen also produce die casting machine auxiliary equipment, such as industrial robots, chiller, auto ladle, sprayer and so on.

We can help our customer select most suitable die casting materials depend on the specific product requirements and production conditions.