Hot chamber die casting machine price range of hot chamber die-casting machine is wide, ranging from $10000 to $500000.

And the specific price needs to be further confirmed according to the model, brand and procurement channels.

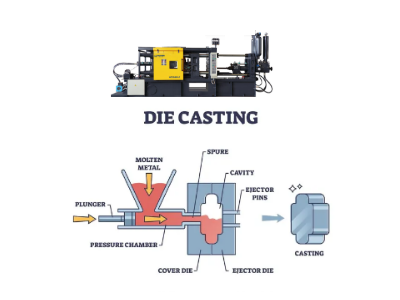

Hot chamber die casting machines are industrial equipment used to inject molten metal into the mold cavity and cool it to form.

Their main feature is that the injection chamber is connected to the molten metal crucible.

They are usually used to produce castings of low-melting-point metals such as zinc, magnesium.

Hot chamber die casting machines have the advantages of compact structure, simple operation, high production efficiency and high degree of automation.

They are suitable for mass production of small parts with complex shapes, such as automotive parts and electronic device casings.

Hot chamber die casting machine type

- Oversized die-casting machine

- Medium-sized chamber die casting machine

Oversized die-casting machine

These equipment are mainly used in the production of large parts in industries such as automobiles and home appliances.

Medium-sized chamber die casting machine

The price of a medium-sized hot chamber die casting machine is usually lower than that of an oversized die casting machine.

But the exact price needs to be determined based on the specific specifications and capabilities of the equipment.

Haichen Hot Chamber Die Casting Machine

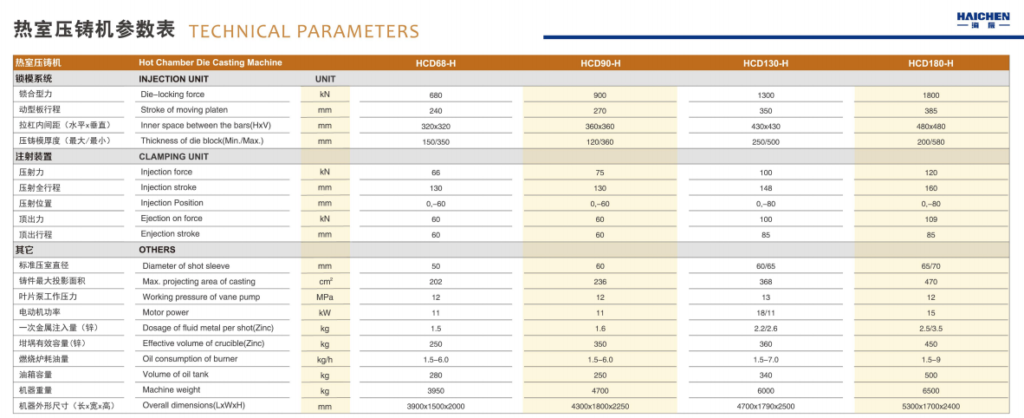

We manufacture advanced hot die-casting machines from 160 up to 1800 kN locking force.

From a single machine to a fully integrated die-casting cell, we build customized solutions for your foundry.

Every die-casting system is engineered to meet your precise production needs.

Haichen Hot Chamber Die Casting Machine prices

Haichen die casting machine is suitable for precision metal die casting of materials such as zinc alloy.

This model has different models such as ordinary type, strengthened type, automatic type, etc., which is suitable for jewelry, hardware and other fields.

The price of a hot chamber die casting machine varies depending on the model, capacity, and supplier.

For example, a 50-ton horizontal high-pressure hot chamber die casting machine from the Haichen brand costs $18,000 or $17,700.00 (two or more).

Factors influencing prices

Locking force size: The locking force is the primary factor influencing the price. The greater the locking force, the higher the price of the press machine is usually.

For instance, the small-scale press machine produced by Haichen with a locking force of less than 50 tons typically costs less than 20,000 US dollars.

While large-scale press machines such as 2,000 tons can cost several hundred thousand US dollars.

Automation level: Fully automatic models are 20% to 50% more expensive than semi-automatic models, but in the long run, they can save labor costs.

Brand premium: Equipment from well-known brands is usually 15% to 25% more expensive than that of ordinary brands, but it comes with better after-sales service.

For instance, Haichen can provide customers with online or offline installation guidance services as well as after-sales support for accessories.

Configuration differences: Configuration differences are also a key factor. Different injection molding machines have significant variations in their injection systems, control systems, and clamping mechanisms.

Haichen’s injection molding machines all use servo control systems, which will increase the price.

Technical and market factors: Technological advancements, raw material costs, market competition, etc. also affect prices.

Price Trend and Market Analysis

According to the report of Bergers Consulting, the price trend and sales volume analysis of the main types of die casting machines in the Chinese market from 2019 to 2024.

Shows that the price of hot chamber die casting machines is affected by a variety of factors.

Including market demand, technological progress and raw material prices.

The 2024-2029 sales forecast of the main types of die casting machines in the Chinese market shows that the sales of hot chamber die casting machines will show an increasing trend.

Factors influencing prices

- Market size and growth trends

- Market supply and demand

- Technological innovation and product upgrading

- Trends in market prices

- Industry Prospect and Investment Opportunities

Market size and growth trends

According to the “China Die Casting Machine Market Size and Growth Analysis 2024” report.

The global and Chinese die casting machine market size in 2023 will be 17.309 billion yuan (RMB) and 6.107 billion yuan respectively.

The global die casting machine market size is expected to grow at an average growth rate of 6.35% during the forecast period and reach 25.311 billion yuan in 2029.

Although the report does not separately list the specific market size of hot chamber die casting machines.

It can be speculated that the market size of hot chamber die casting machines, as an important part of the die casting machine market, will also grow.

Market supply and demand

The “2024-2030 China Die Casting Market In-depth Analysis and Market Supply and Demand Forecast Report” .

Points out that the development of the die casting machine industry is affected.

By the economic environment, social environment, policy environment, technical environment and industrial environment.

Hot chamber die casting machines are mainly used to produce smaller size parts.

Such as luggage metal parts, zipper pulls, toys, etc,and the materials are mostly zinc alloy and copper alloy.

With the increase in demand in downstream application fields, especially the rapid development of automobile manufacturing, home appliances, motorcycles.

And other industries, the market demand for hot chamber die casting machines will continue to grow.

Technological innovation and product upgrading

Haichen has always maintained a leading position in the industry in terms of technological innovation.

Constantly breaking through key core technologies and setting a new record in the global ultra-large die-casting machine industry.

The hot chamber die casting machines provided by Haichen are efficient, green and intelligent.

Which can meet the diversified die casting production needs of different industries.

Trends in market prices

According to the report “Die Casting Machine Market – Global Supply and Demand Analysis”.

The trend of product price changes is one of the important contents of market analysis.

Although specific price data is not provided.

It can be speculated that with the advancement of technology and the increase in market demand.

The price of hot chamber die casting machines may show a steady and rising trend.

Industry Prospect and Investment Opportunities

As an important equipment in automobile manufacturing, the market demand of hot chamber die casting machine will increase with the growth of the automotive industry.

In addition, with the development of electric vehicles and new materials, the role of hot chamber die casting machines in the field of automobile design.

And manufacturing is becoming increasingly important, which provides investors with good investment opportunities.

In conclusion, the price differences among different tonnage and brand of hot chamber die casting machines are mainly influenced by multiple factors.

Such as clamping force, equipment type, automation level, brand, configuration, technology, market and application requirements.

Haichen’s addition

There are also maintenance costs for hot chamber die casting machines, which mainly include regular cleaning and maintenance, hydraulic system maintenance, electrical system maintenance, mold clamping part maintenance, injection part maintenance, lubrication part maintenance and cooling system maintenance.

Long-term operating costs include one-time machine investment, installation costs, depreciation expenses, labor costs, overheads and other operating costs.