Magnesium-aluminum alloy die casting continues to expand its application in the fields of automobiles, electronics, aerospace, etc. due to its lightweight, high efficiency and process innovation.

In the future, it is necessary to carry out alloy design (such as rare earth element regulation), process upgrade (vacuum/ultra-vacuum technology) and standardization construction.

Haichen has more than 20 years of experience in magnesium and aluminum alloy die-casting equipment, and will show you more technical details between them.

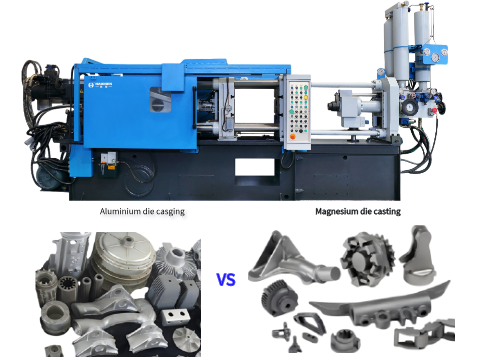

Comparison of two die casting materials

- Density and Weight Reduction

- Strength-to-Weight Ratio

- Production Efficiency

- Applications vs. Limitations

- Material Selection Guidelines

Density and Weight Reduction

- Magnesium Density: 1.8 g/cm³

- Aluminum Density: 2.7 g/cm³

- Weight Difference: Magnesium alloys are ~33% lighter than aluminum alloys.

Practical Examples:

- Automotive rear longitudinal beams:

- Aluminum weight: 190 kg → Magnesium weight: 130 kg (31.5% reduction).

- Powertrain/electrical components: Up to 40–50% weight savings, depending on design.

Strength-to-Weight Ratio

- Magnesium: Highest strength-to-weight ratio among structural metals.

- Example Comparison:

- AZ91E (T6 temper) tensile strength: ~275 MPa (similar to aluminum 356).

- Advantage: Magnesium offers 50% higher strength per unit mass due to lower density.

- Design Impact: Enables thinner walls or compact geometries without sacrificing performance.

Production Efficiency

- Magnesium Benefits:

- Lower latent heat → Faster solidification → Shorter cycle times.

- Reduced adhesion to molds → Longer die life.

- Machine Requirements:

- Magnesium: 160-ton machine.

- Aluminum: 550–650-ton machine.

- Cost Savings: Lower energy use, smaller equipment, and hot-chamber die casting compatibility reduce processing steps.

Applications vs. Limitations

- Magnesium Applications:

- Automotive: Steering columns, valve covers, brackets.

- Consumer electronics: Laptop frames, camera bodies.

- Key Limitations:

- Poor high-temperature creep resistance (e.g., AZ91D degrades above 100°C).

- Lower corrosion resistance vs. aluminum.

Material Selection Guidelines

| Factor | Choose Magnesium | Choose Aluminum |

|---|---|---|

| Weight Priority | ✓ (Superior lightweighting) | ✗ |

| High-Temperature Use | ✗ | ✓ (Better stability) |

| Corrosion Resistance | ✗ (Requires coatings) | ✓ (Naturally resistant) |

| Cost Efficiency | ✓ (Lower processing costs) | ✗ (Higher machine/energy costs) |

Magnesium die casting offers ~33% weight reduction and superior production efficiency but faces challenges in high-temperature and corrosive environments.

- Aluminum remains dominant for applications requiring thermal stability or minimal corrosion.

- Future trends (e.g., EVs, aerospace) favor magnesium, driving research into high-performance alloys (e.g., rare-earth-enhanced Mg).

Advantages of Magnesium in Die Casting

- Production Efficiency and Cost Advantages

- Lightweighting and Design Flexibility

- Process Performance Enhancements

- Environmental and Safety Improvements

- Diverse Alloy Systems

- Industry Applications

- Challenges and Future Directions

Production Efficiency and Cost Advantages

- Shorter Cycle Times: Magnesium’s solidification latent heat is ~30% lower than aluminum, and its low affinity for iron enables faster mold cooling, reducing cycle times by 20–30% while doubling mold lifespan compared to aluminum die casting. For example, magnesium alloy seat frames achieve 20–30% shorter cycles.

- Hot Chamber Die Casting Compatibility: Magnesium can be processed via hot chamber die casting (unlike aluminum, which requires cold chamber), offering higher automation, reduced melt oxidation, and suitability for high-volume small components.

- Cost-Effectiveness: Lower equipment investment and comparable melt cost per volume to aluminum make magnesium ideal for mass production.

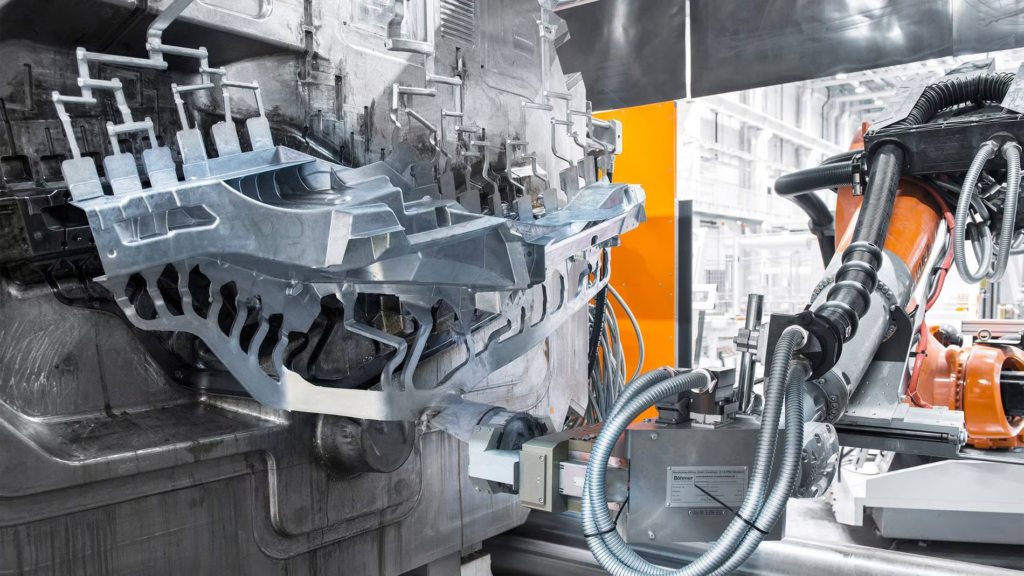

Lightweighting and Design Flexibility

- Ultra-Thin Wall Capability: Magnesium can produce walls as thin as 1–1.5 mm (vs. 2–2.5 mm for aluminum), enabling 40–60% weight reduction in automotive steering wheels, dashboards, etc.

- Complex Geometry: Superior fluidity allows intricate mold filling, ideal for thin-walled electronics housings and large structural parts like automotive chassis.

Process Performance Enhancements

- Low Porosity and High Integrity: Vacuum die casting (e.g., Alcan’s High-Q-Cast) and super vacuum die casting (SVDC) reduce gas pores, boosting tensile strength and elongation. SVDC enables magnesium alloys to achieve 180 MPa yield strength and 10% elongation.

- High Material Utilization: Near-net-shape forming via high-pressure die casting (HPDC) and semi-solid injection molding (Thixomolding) minimizes post-processing and waste.

Environmental and Safety Improvements

- Energy Savings: Semi-solid injection molding reduces energy consumption by 30%+ by processing in a semi-molten state, eliminating SF6 greenhouse gas usage.

- Safety: Closed semi-solid processes mitigate melt exposure and combustion risks.

Diverse Alloy Systems

- Customizable Alloys: Mg-Al (low-cost, corrosion-resistant), Mg-Zn (high-strength), and Mg-RE (high-temperature creep-resistant) alloys cater to varied applications. Rare-earth alloys like QE22A withstand 300°C for aerospace skins and missile components.

Industry Applications

- Automotive: Structural parts (e.g., shock towers, cross-car beams) achieve 60% weight reduction with cost savings.

- Aerospace and Electronics: High-strength alloys for satellite frames and thin-walled electronics housings.

Challenges and Future Directions

Traditional die casting faces porosity and shrinkage issues, but vacuum and squeeze casting technologies have improved performance. Future focus includes low-cost rare-earth alloys and optimized parameters for high-temperature structural applications.

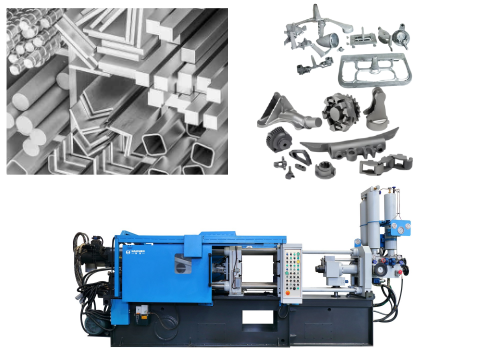

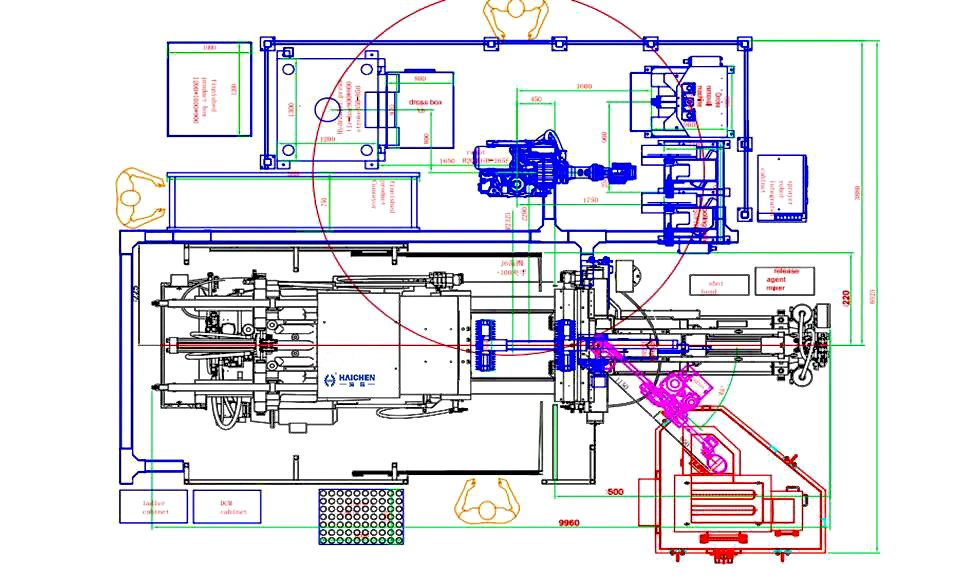

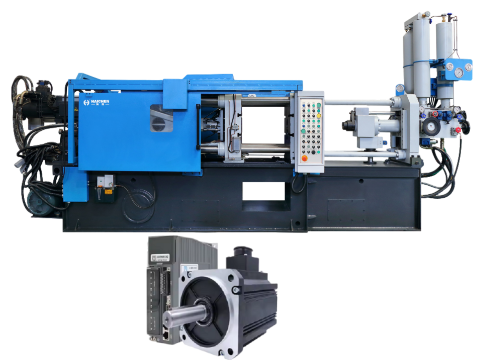

HAICHEN: For your magnesium alloy cold-chamber die-casting equipment

Haichen specializes in manufacturing advanced die-casting machines that meet the highest standards of precision and reliability. Our equipment can simultaneously handle both aluminum and magnesium alloy die-casting processes, ensuring consistent quality and efficiency in the production of high-strength, lightweight components. Whether you need aluminum or magnesium alloy die casting, Haichen provides professional equipment and technical support to help you achieve your production goals.

Magnesium alloys typically have higher raw material and processing costs than aluminum alloys, which increases overall production costs. Therefore, choosing a more precision-designed die-casting machine is particularly important.

Magnesium die casting drives lightweight innovation across automotive, aerospace, and electronics industries, with ongoing advancements unlocking its full potential.

Contact Haichen die casting machine for more technical details.