High-pressure die-casting machines (HPDCMs) find unavoidability through many industries and the importance that Die casting machine Hydraulic Oil plays in them cannot be understated. In most machines, hydraulic oil is used for their proper functioning. Any stoppage in lubrication can lead to gigantic problems.

The choice of Die casting machine Hydraulic Oil varies with Machines specifications and operating conditions.

Hydraulic oil plays, in the most optimistic words, a very important function inside HPDCMs since it is high-pressure fuel for these machines. In light of major factors that may contribute to pump failure, this paper will underscore the necessity of contacting lubrication specialists in efforts geared toward achieving optimum running conditions for any die casting machine. This paper will also discuss hydraulic oil prices and what makes for good lubrication equipment.

Many types of die casting hydraulic Oils

Common types include:

- Anti-Wear Hydraulic Oil (AW)

- High Viscosity Index (HVI) Hydraulic Oil

- High-Cleanliness Hydraulic Oil

- Other Types

Anti-Wear Hydraulic Oil (AW)

- ISO VG46 Anti-Wear Oil: Widely used for general-purpose applications (e.g., hot-chamber die casting). Provides excellent lubrication and compatibility with hydraulic systems.

- ISO VG68 Anti-Wear Oil: Recommended for cold-chamber die-casting machines (e.g., 1000T machines) and high-temperature environments. Brands like Hercules ZONA VG68 or Caltex 68 are preferred for their high cleanliness and thermal stability.

High Viscosity Index (HVI) Hydraulic Oil

- Multi-Grade HVLP Oil: Examples include Oest HVI 46 and HVI 68. These oils maintain stable viscosity across wide temperature ranges, complying with DIN 51524 Part 3 standards. Ideal for energy-efficient systems.

- Special Multi-Grade Oils: Such as HVLP 22-330/32-330, designed for extreme climates or large temperature fluctuations.

High-Cleanliness Hydraulic Oil

- Essential for precision systems (e.g., cold-chamber machines). Examples like Hercules ZONA ISO VG68 minimize sludge and contamination risks in hydraulic circuits.

4. Other Types

- Biodegradable Hydraulic Oil: Eco-friendly options like Griflube series for environmentally sensitive applications.

- Phosphate Ester/Water-Glycol Fluids: Used in specific systems but require compatibility checks for pumps and seals.

Key Selection Guidelines

- Avoid Substitutions: Never replace recommended oils with alternatives to prevent system failures.

- Viscosity Matching:

- VG46 (e.g., ISO VG46 Anti-Wear Oil) for hot-chamber machines.

- VG68 for cold-chamber machines.

- Cleanliness: Flush tanks thoroughly during oil changes to remove debris.

- Standards Compliance: Prioritize oils meeting DIN 51524 Part 2 (HLP) or Part 3 (HVLP).

Recommended Brands

| Oil Type | Example Brands/Products | Applications |

|---|---|---|

| ISO VG46 Anti-Wear | 46# Anti-Wear Hydraulic Oil | General hot-chamber machines |

| ISO VG68 Anti-Wear | Hercules ZONA VG68, Caltex 68 | Cold-chamber/high-temperature |

| Multi-Grade HVLP | Oest HVI 46, HVI 68 | Wide temperature ranges |

| High-Cleanliness Oil | Hercules ZONA Series | Precision hydraulic systems |

Always consult the machine manual (e.g., HCD1080-C cold-chamber specifications) and work with oil suppliers for technical guidance.

Die casting machine Hydraulic Oil practical application

The hydraulic oil in die casting machines plays a critical role in ensuring system efficiency, safety, and longevity. Its application involves multiple aspects, including core functionality, maintenance, safety, and auxiliary processes, as outlined below:

- Core Functions

- Maintenance Management

- Safety & Environmental Compliance

- Auxiliary Applications

- Efficiency & Lifespan Optimization

Core Functions

- Power Transmission & Lubrication:

Hydraulic oil acts as the power transmission medium in the hydraulic system, enabling precise control of high-pressure actions (e.g., clamping forces up to thousands of tons). It also lubricates moving components (pumps, valves, cylinders) to minimize wear. For instance, in cold-chamber die casting, hydraulic oil ensures rapid injection of molten metal into molds. - Cooling:

High pressure and friction generate heat in the system. Hydraulic oil must work with cooling systems (e.g., heat exchangers) to maintain oil temperature within 40–60°C, preventing viscosity loss or oxidation. Stable temperatures extend oil life and enhance system efficiency.

Maintenance Management

- Regular Replacement:

Hydraulic oil should be replaced every 2,000 operating hours, with thorough tank cleaning to remove contaminants (metal particles, dust) that degrade performance. - Oil Selection:

Use high-purity, anti-wear hydraulic oils (e.g., Hercules ZONA ISO VG68, Caltex 68) with fire-resistant properties (e.g., water-glycol-based fluids) to reduce flammability risks. Performance parameters (viscosity, thermal stability) should drive selection over brand loyalty.

Safety & Environmental Compliance

- Fire Resistance:

Fire-resistant hydraulic oils (certified under standards like ISO 12922) are critical in high-pressure environments to prevent ignition. Water-glycol fluids are widely used for this purpose. - Waste Oil Handling:

Used hydraulic oil contains additives and thermal degradation byproducts, classified as hazardous waste (Class B3). It must be disposed of via licensed facilities to avoid environmental harm.

Auxiliary Applications

- Mold Temperature Control:

While hydraulic oil primarily serves the hydraulic system, dedicated thermal oil systems (e.g., hot runner channels) may use high-temperature oils to preheat molds, improving casting quality. These oils are managed separately from hydraulic oils. - Lubrication Coordination:

Die lubricants (e.g., oil-water emulsions in a 30:1 ratio) aid mold release and cooling. The oil component (heavy residual or synthetic oils) supports demolding, while water evaporates to cool the mold surface. These lubricants are distinct from hydraulic oils and must not be mixed.

5. Efficiency & Lifespan Optimization

- Cooling System Optimization:

Stable oil temperature via heat exchangers reduces component wear and enhances lubrication, extending equipment life. - Mold Longevity:

High-quality tool steel molds, combined with stable hydraulic system operation, significantly improve mold durability.

Overall

Effective hydraulic oil management in die casting requires balancing performance, maintenance, safety, and sustainability. Key practices include selecting fire-resistant oils, adhering to replacement schedules, maintaining temperature control, and ensuring proper waste disposal. These steps optimize system reliability, reduce downtime, and mitigate environmental risks.

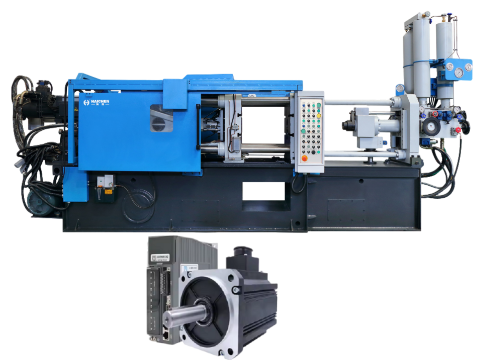

Haichen die casting machine is suitable for a variety of hydraulic oils

Haichen die-casting machines are designed to be compatible with various types of hydraulic oils, as demonstrated by the following features:

- Specified Hydraulic Oil Grades

- Multi-Viscosity Compatibility

- Support for Fire-Resistant Die casting machine Hydraulic Oils

- Die casting machine Hydraulic Oil Quality and Maintenance Requirements

- Global Component Standards

Specified Hydraulic Oil Grades

During initial commissioning, ISO VG 46 anti-wear hydraulic oil (L-HM grade) is explicitly required to ensure system cleanliness and component longevity. The machine supports hydraulic oils classified under ISO viscosity grades (22, 32, 46, 68), with VG 46 being the standard for Haichen machines. This confirms compatibility with at least VG 46 HM-grade oils.

Multi-Viscosity Compatibility

The hydraulic system accommodates oils with different viscosity grades (e.g., 32, 46, 68), as evidenced by recommendations for oils like:

- Shell Tellus S2 MX32, MX46, MX68

- Sinopec Great Wall 48#, 68#

- Haijiang HV46, HV68

This flexibility is enabled by Haichen’s multi-stage filtration and temperature control systems, which maintain oil stability across viscosity ranges.

Support for Fire-Resistant Die casting machine Hydraulic Oils

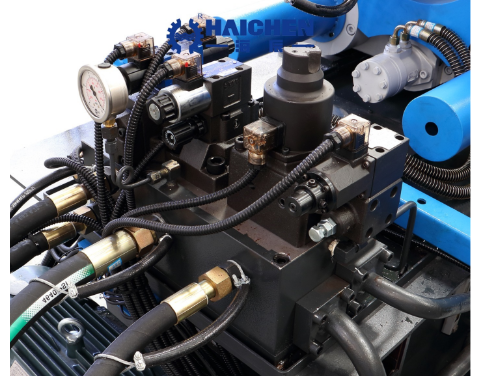

While not explicitly stated in Haichen manuals, the hydraulic system’s dedicated oil tank, high-pressure filtration (10μm), and temperature regulation (20–55°C) allow compatibility with fire-resistant fluids like water-glycol types (e.g., HOUGHTON SAFE 620), provided they meet ISO cleanliness standards (NAS 9 or better).

Die casting machine Hydraulic Oil Quality and Maintenance Requirements

- Filtration System: Includes suction filters (80μm), high-pressure filters (10μm), and bypass filters (3μm) to maintain oil cleanliness.

- Temperature Control: Auto-preheating and water-cooling systems stabilize oil viscosity.

- Monitoring: Regular checks for viscosity, moisture, acidity (≤0.5 mg KOH/g), and particle counts (NAS ≤9) ensure compatibility with diverse oils.

Global Component Standards

Hydraulic components from brands like Vickers, Rexroth, and Parker (used in Haichen machines) are certified for ISO/DIN-compliant oils, ensuring broad compatibility.

Summary of Compatible Oils

- Standard Anti-Wear Oils: HM-grade oils (VG 32, 46, 68).

- Fire-Resistant Fluids: Water-glycol types (for high-temperature or safety-critical environments).

- Major Brands: Shell, Sinopec, Haijiang, and other ISO-compliant oils.

Critical Notes:

- Always prioritize the VG 46 HM oil specified in the manual for initial filling.

- For alternative oils (e.g., VG 68 or fire-resistant fluids), consult Haichen’s technical team to validate compatibility.

- Maintain strict oil cleanliness (NAS ≤9) and monitor degradation indicators (acid number, water content) to avoid system damage.

Feel free to contact Haichen for more details on die casting machine technology.