Die casting machine safety systems are a combination of multiple protection: physical barriers (guard doors), detection devices (travel switches, lasers), control system interlocks, emergency braking (safety valves, emergency stop switches) and automatic shutdown functions that work together to counteract the risks of mechanical injuries, metal splashes and system failures.

Whether the safety system of a die-casting machine is complete and whether the user-friendly design is in line with the purpose of protecting the operator is an important measure to reflect the quality level of the equipment.

Die casting is a high-pressure, high-temperature manufacturing process that involves inherent risks. However, with proper safety protocols, equipment maintenance, and worker training, these risks can be effectively managed.

Below is a detailed breakdown of safety considerations in die casting:

- Key Hazards in Die Casting

- Safety Measures and Precautions

- Best Practices for Safe Die Casting

- Compliance with Safety Standards

- Common Incidents and Mitigation

- Advances in Die Casting Safety

Key Hazards in Die Casting

| Risk Factor | Description |

|---|---|

| Molten Metal Exposure | Handling metals like aluminum (660°C) or zinc (420°C) poses severe burn risks. |

| High-Pressure Systems | Machines operate at pressures up to 200 MPa, risking explosions or component failure. |

| Toxic Fumes | Zinc oxide fumes (metal fume fever) or aluminum dust can harm respiratory systems. |

| Noise Pollution | Machinery noise (85–100 dB) may cause hearing damage over time. |

| Mechanical Hazards | Moving parts (e.g., ejector pins, clamping units) risk crushing or entanglement. |

| Ergonomic Risks | Heavy die handling (up to 10+ tons) can lead to musculoskeletal injuries. |

Safety Measures and Precautions

- Personal Protective Equipment (PPE)

- Heat-resistant gloves, aprons, and face shields to protect against molten metal splashes.

- Respirators (N95 or powered air-purifying) to filter toxic fumes.

- Hearing protection (earplugs or muffs) for noise reduction.

- Machine Safety Features

- Guarding systems to prevent access to moving parts during operation.

- Emergency stop buttons and light curtains for instant shutdown in emergencies.

- Pressure relief valves to prevent over-pressurization.

- Ventilation and Air Quality

- Local exhaust ventilation (LEV) systems to remove fumes at the source.

- Dust collectors for aluminum or magnesium particulates (risk of combustion).

- Training and Protocols

- Lockout/Tagout (LOTO) procedures during maintenance to prevent accidental startups.

- Regular drills for molten metal spill response and fire emergencies.

- Certification programs (e.g., OSHA 30-Hour for metal casting).

- Automation and Robotics

- Robotic arms for handling dies, reducing worker exposure to high-risk zones.

- Automated ladling systems to minimize manual pouring of molten metal.

Best Practices for Safe Die Casting

- Regular Maintenance: Inspect dies, hydraulic systems, and cooling lines to prevent failures.

- Material Handling: Use preheated ladles to avoid moisture-induced explosions (e.g., steam from molten aluminum).

- Housekeeping: Keep floors dry and free of debris to prevent slips or fires.

- Health Monitoring: Conduct annual hearing tests and lung function checks for workers.

Compliance with Safety Standards

- OSHA Regulations:

- 29 CFR 1910 Subpart O (Machinery and Machine Guarding).

- 29 CFR 1910.147 (Control of Hazardous Energy – LOTO).

- NFPA Standards: NFPA 484 (Combustible Metals) for handling magnesium or aluminum dust.

- ISO Certifications: ISO 45001 (Occupational Health and Safety Management Systems).

Common Incidents and Mitigation

- Molten Metal Burns:

- Cause: Splashes from improperly sealed dies or overfilled molds.

- Solution: Use robotic pouring systems and real-time leak detection sensors.

- Machine Malfunctions:

- Cause: Worn-out hydraulic hoses or faulty pressure sensors.

- Solution: Predictive maintenance with IoT-enabled condition monitoring.

Advances in Die Casting Safety

- Smart Sensors: Detect abnormal pressure/temperature spikes and trigger shutdowns.

- Virtual Reality (VR) Training: Simulate high-risk scenarios for safer worker education.

- Low-Emission Alloys: Zinc-aluminum alloys (ZA-8) reduce fume generation.

Types of safety in die casting machine

Die casting machines involve high-pressure operations, molten metals, and heavy machinery, making safety systems critical to protect workers, equipment, and the environment. Below are the primary types of safety mechanisms integrated into die casting machines, categorized by their purpose and application:

- Physical Safety Guards and Barriers

- Control System Safety

- Operator Safety Features

- Environmental and Fire Safety

- Material Handling Safety

- Maintenance and Lockout/Tagout (LOTO)

- Compliance with Safety Standards

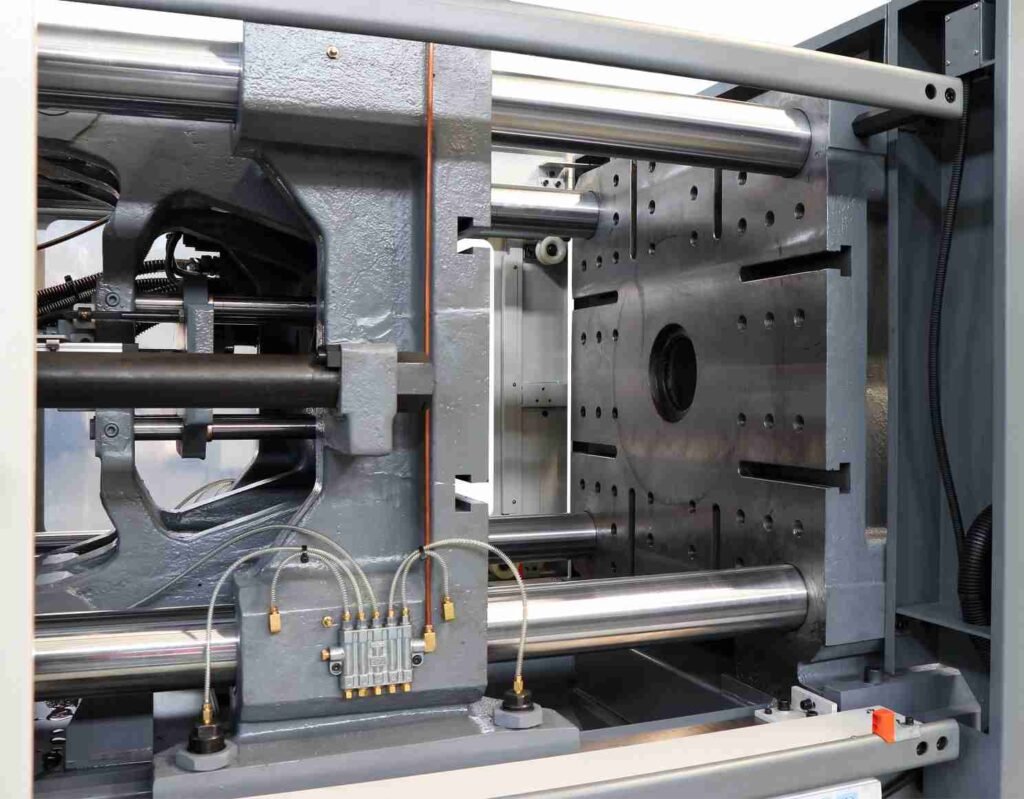

Physical Safety Guards and Barriers

- Fixed Guards:

- Permanently enclose hazardous areas (e.g., mold closing zones, injection units).

- Made of steel or polycarbonate to withstand impact and heat.

- Interlocked Guards:

- Automatically shut down the machine when opened (e.g., light curtains, door switches).

- Ensure the machine stops if a worker enters the danger zone.

- Safety Fences:

- Surround the machine perimeter to restrict unauthorized access.

Control System Safety

- Emergency Stop (E-Stop) Buttons:

- Instantly halt all machine operations when pressed.

- Strategically placed at multiple points around the machine.

- Two-Hand Control Systems:

- Require both hands to activate the cycle, preventing accidental activation.

- Pressure and Temperature Sensors:

- Monitor hydraulic pressure and molten metal temperature to prevent over-pressurization or overheating.

- Safety PLCs (Programmable Logic Controllers):

- Advanced controllers detect faults (e.g., misaligned molds, sensor failures) and trigger shutdowns.

Operator Safety Features

- Heat-Resistant PPE:

- Gloves, aprons, face shields, and helmets to protect against molten metal splashes.

- Ergonomic Design:

- Adjustable workstations and robotic assistance reduce strain during die changes or maintenance.

- Training Systems:

- VR simulations for hazard awareness and emergency response drills.

Environmental and Fire Safety

- Ventilation Systems:

- Extract toxic fumes (e.g., zinc oxide) and reduce airborne particulates.

- Fire Suppression Systems:

- Automatic sprinklers or CO₂ extinguishers for magnesium fires (highly combustible).

- Dust Collection:

- Removes flammable aluminum or magnesium dust from the workspace.

Material Handling Safety

- Robotic Automation:

- Robots handle molten metal pouring, part ejection, and die lubrication, minimizing human interaction with hazardous zones.

- Ladle Preheating:

- Prevents moisture-induced explosions when pouring molten metal.

- Tilt-Pour Furnaces:

- Automate metal transfer safely, reducing spill risks.

Maintenance and Lockout/Tagout (LOTO)

- Lockout/Tagout Systems:

- Isolate energy sources (hydraulic, electrical) during maintenance to prevent accidental startups.

- Maintenance Mode:

- Limits machine speed and pressure during repairs.

- Warning Alarms:

- Audible/visual alerts before machine activation.

Compliance with Safety Standards

- OSHA Regulations:

- 29 CFR 1910 (Machinery Guarding, LOTO).

- ISO Standards:

- ISO 13849 (Safety of Machinery) and ISO 12100 (Risk Assessment).

- NFPA Guidelines:

- NFPA 70E (Electrical Safety) and NFPA 484 (Combustible Metals).

Key Safety Technologies in Modern Die Casting Machines

| Technology | Function | Example |

|---|---|---|

| Light Curtains | Detect intrusions into danger zones | SICK C4000 Safety Light Curtains |

| Pressure Relief Valves | Prevent over-pressurization in hydraulic systems | Parker Hannifin Valves |

| Thermal Imaging Cameras | Monitor die/metal temperature in real-time | FLIR A Series Thermal Cameras |

| Smart Sensors | Detect misaligned dies or leaks | Balluff BVS Safety Sensors |

Why These Safety Systems Matter

- Worker Protection: Prevent burns, crushing injuries, and respiratory issues.

- Equipment Longevity: Avoid costly damage from overloading or malfunctions.

- Regulatory Compliance: Meet OSHA, ISO, and industry-specific standards.

- Operational Efficiency: Minimize downtime from accidents or machine failures.

Die casting machine safety is multi-layered, combining physical barriers, automated controls, operator training, and environmental safeguards. Leading manufacturers like Bühler, Toshiba Machine, and L.K. Technology integrate advanced safety systems (e.g., AI-driven hazard detection) to ensure compliance and protect workers. Investing in these safety measures not only reduces risks but also enhances productivity and sustainability in die casting operations.

Haichen die casting machine safety

The safety design of Haichen cold chamber die casting machine involves multiple levels, and the specific measures are as follows:

- Safety operation specifications

- Equipment design and safety standards

- Maintenance and inspection

- Operator training and emergency measures

- Warranty and technical support

- Typical cases and risk prevention

Safety operation specifications

Two-handed operation requirements

- When operating the mold closing button, both hands must be used, and single-handed operation is prohibited to prevent accidental touch.

- This design reduces the risk of accidental start-up through physical operation restrictions.

- Personal protective equipment (PPE)

- The operator needs to wear a full set of protective equipment, including safety glasses, heat-resistant gloves, masks, protective clothing and safety shoes to resist high-temperature metal splashes and mechanical injuries.

- Protective door setting

- The equipment is equipped with a safety protective door to prevent molten metal splashes and mechanical pinching. It is strictly forbidden to disassemble or disable the protective door at will during production.

- The protective door can block the metal liquid splashing from the mold parting line to reduce the risk of burns.

Equipment design and safety standards

Compliance with international safety certification

The design of Haichen die casting machine refers to Chinese machinery industry standards (such as JB/T8083-2000) and EU CE safety standards, and the key components are verified by finite element analysis. Structural strength.

Automatic control technology

Adopt Siemens PLC control system, support multi-language interface (Chinese, English, etc.), and equipped with magnetic scale to monitor injection position in real time, and accurately control the four-stage injection process through computer to avoid safety hazards caused by manual adjustment.

The hydraulic system uses well-known European and American brand components (such as Vickers, Yuken) to ensure pressure stability and response speed.

Maintenance and inspection

Lubrication system maintenance

The new machine needs to be manually lubricated once every half month in the first six months, and once a month thereafter; the central lubrication system automatically performs once every 500~700 molds.

Insufficient lubrication will cause wear of mechanical parts, which may cause hydraulic leakage or jamming, affecting safe operation.

Regular inspection items

The hydraulic system sealing needs to be checked daily, aging seals need to be replaced in time, and hydraulic oil and filter elements need to be replaced regularly to prevent contaminant accumulation.

Hydraulic oil contamination may cause abnormal system pressure and cause equipment out of control.

Operator training and emergency measures

- Training content

- The training covers equipment control, molten metal processing, emergency shutdown procedures, maintenance procedures and PPE usage specifications.

- Untrained operators may cause accidents due to misoperation, such as molten metal leakage or mold pinching.

- Emergency protection device

- The equipment is equipped with electronic protection devices, such as low-pressure protection function and lubrication system disconnection alarm function, which can automatically shut down under abnormal conditions.

Warranty and technical support

- Warranty conditions

- During the warranty period, the equipment must be operated correctly and the specified materials must be used. It is prohibited to dismantle the mold bolts or use inferior hydraulic oil without authorization, otherwise the warranty may be invalid.

- Remote support and spare parts supply

- Haichen provides online technical support and engineer on-site service. The equipment is shipped with wearing parts to meet short-term use needs.

Typical cases and risk prevention

- Molten metal splash: protective doors and masks can effectively block splashing.

- Mold pinching: prevent limbs from entering the dangerous area through two-handed operation and protective door interlocking mechanism.

- Hydraulic system failure: regularly replace the filter element and maintain the oil circuit to avoid equipment loss of control caused by abnormal pressure.

Haichen die-casting machine ensures safety through multiple dimensions such as design compliance, automated control, strict maintenance and operation training. At the same time, users are required to follow the operating specifications to give full play to the protection effect.

Die casting can be performed safely with rigorous adherence to protocols, advanced automation, and continuous training. While risks like molten metal exposure and high-pressure hazards exist, modern safety technologies—such as robotics, smart sensors, and improved PPE—have significantly reduced workplace injuries.

For facilities, investing in safety is not just regulatory compliance—it’s a critical factor in sustaining productivity and worker well-being.

Contact Haichen We will share the safety knowledge about die casting process as much as possible.