Hot chamber die casting is chosen for:

- High precision and high quality

- High production efficiency

- High degree of automation

- Wide range of applications

The integrated furnace allows for faster cycle times and higher production rates compared to cold chamber die casting.

It’s particularly advantageous for zinc, magnesium, lead, and tin alloys, which are commonly used due to their fluidity and quick solidification.

Why choose hot chamber die casting machine

High precision and high quality

Hot chamber die casting machines are capable of producing castings with high dimensional accuracy and good surface quality.

Its high-precision control ensures that the dimensional tolerance of the casting is extremely small, and the surface finish can reach 5~8 grades, or even higher.

Which is suitable for the manufacture of precision electronic components and automotive parts.

In addition, because the molten metal flows in a closed channel, oxidized inclusions are not easily entrapded, which improves the quality of the casting.

High production efficiency

In addition, the hot chamber die casting machine has the characteristics of fast cycle and can achieve continuous production.

Which can produce thousands of times per hour, especially suitable for high-volume production needs.

This high efficiency not only shortens the production cycle, but also reduces the production cost per unit of product and improves the competitiveness of the enterprise.

High degree of automation

Hot chamber die casting machines are usually equipped with advanced automation control systems.

Which can realize the automatic operation of the whole process from mold preparation to finished product removal.

Reducing manual intervention, reducing production costs and improving production stability.

Wide range of applications

The hot chamber die-casting machine is suitable for the die-casting of a variety of metal materials.

Especially the production of low-melting alloys (such as zinc, lead, tin, etc.) and some magnesium alloys.

These materials have good flow and formability at high temperatures, making them suitable for manufacturing small to medium-sized complex parts.

Significant economic benefits

Due to the long mold life of the hot chamber die casting machine, the precise size of the castings and the smooth surface.

The need for subsequent processing is reduced, which in turn reduces material and processing costs.

In addition, the initial investment cost of the hot chamber die casting machine is relatively low, making it suitable for large-scale production.

Hot chamber die casting machine technical advantages

- Molten metal recycling

- Precise temperature control

- Strong applicability

- Energy-saving and efficient production

- Environmental protection and sustainability

Molten metal recycling

Molten metal flows in a closed channel, reducing metal loss.

Precise temperature control

Through the heating device and cooling system, the temperature and cooling rate of the molten metal can be accurately controlled to ensure the stability and consistency of the casting.

Strong applicability

Suitable for the production of parts of various materials and complex shapes.

Especially suitable for the manufacture of small and thin-walled parts.

Energy-saving and efficient production

The high productivity of the hot chamber die casting machine (3000~7000 times per hour).

And high metal utilization (reducing raw material and energy consumption) make it an important equipment in the production of auto parts.

In addition, its fast cycle times and degree of automation further increase production efficiency.

Environmental protection and sustainability

The scrap rate of the hot chamber die casting machine is low, and the recycling of molten metal reduces material waste.

Which meets the environmental requirements of modern industrial production.

Hot chamber die casting machine application case

- Engine-related parts

- Gearbox related parts

- Body panels

- Lightweight components

- Other key components

Engine-related parts

Hot chamber die-casting machines are widely used in the production of automotive engines.

Such as key components such as cylinder blocks and cylinder heads.

These components require extreme precision and strength, and hot chamber die casting machines are able to ensure that the castings have tight dimensional tolerances.

And a smooth surface quality by precisely controlling pressure, speed and temperature.

Gearbox related parts

Gearbox is one of the core components of automobiles, and many of its parts.

Such as gearbox bodies, need to be produced by hot chamber die-casting machines.

The high efficiency and precision of the hot chamber die casting machine allows it to quickly complete the forming of complex parts.

While reducing the number of subsequent processing steps and increasing production efficiency.

Body panels

Hot chamber die casting machines are also used to produce lightweight parts of automotive bodies, such as body panels.

These components need to be high strength and good corrosion resistance.

And hot chamber die casting machines are able to take advantage of the fluidity, plasticity.

And corrosion resistance of materials such as zinc alloys to meet these requirements.

Lightweight components

With the increasing demand for energy saving, emission reduction and lightweighting in the automotive industry.

Hot chamber die casting machines also play an important role in the production of lightweight components.

For example, by using low-melting metals such as zinc alloys.

Hot chamber die casting machines are able to quickly produce lightweight, high-strength parts, reducing vehicle weight and improving fuel efficiency.

Other key components

In addition to the above-mentioned components, hot chamber die casting machines are also used to produce other important automotive parts such as locks, shaft cores, pulleys, etc.

These parts often have high requirements for material properties and manufacturing precision,

And hot chamber die casting machines can effectively meet these needs due to their high precision and high efficiency.

What are the challenges in hot chamber die casting?

Any metal injection molding process, whether using molten metal or powders, come with their unique challenges, primarily revolving around issues such as flashing and porosity.

However, Haichen team of experts effectively addresses and mitigates these challenges through a combination of strategies.

By combining these factors – meticulous mold design, state-of-the-art machinery, and a skilled team – Haichen effectively mitigate challenges like flashing and porosity in metal hot chamber die casting, ensuring that our products meet the highest standards.

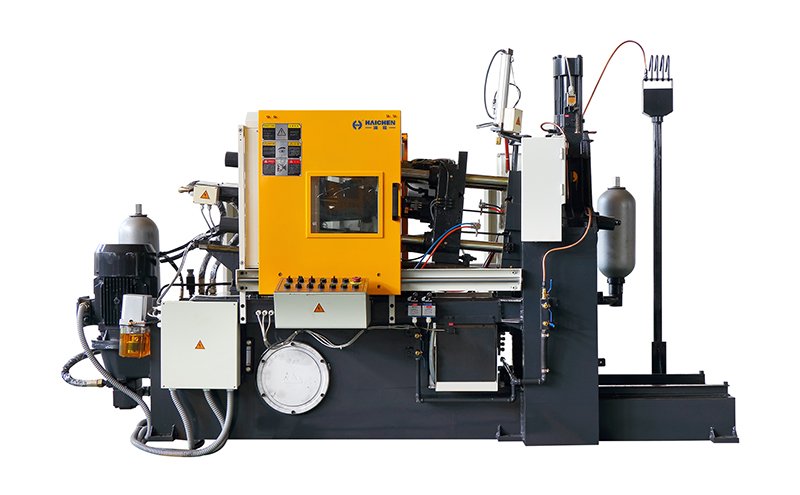

Choose hot chamber die casting machine–Haichen Machine

On the whole, the economic benefits of the hot chamber die casting machine are mainly reflected in the improvement of high production efficiency, high-quality products and market competitiveness.

However, its long-term operating costs are also affected by factors such as equipment maintenance, material costs, and technology refreshes.