Process of Precision Die Casting

Precision die casting is a manufacturing process that involves injecting molten metal into a precision mold under high pressure to produce parts with high accuracy, consistency, and complex geometries. Precision

Precision die casting is a manufacturing process that involves injecting molten metal into a precision mold under high pressure to produce parts with high accuracy, consistency, and complex geometries. Precision

Die casting and forging applications include in the automotive industry, aerospace, industrial machinery and so on. Die Casting and Forging complement each other in industrial manufacturing: the former is good

Die casting is one of the most flexible and innovative manufacturing techniques for fabricating metal parts. Also die casting processes in the manufacturing industry due to its efficiency, precision, and

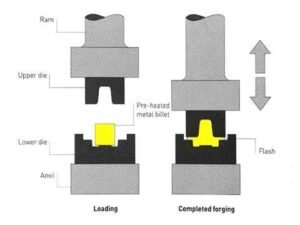

Die Casting and Metal Forging are two different metal forming processes.In metal forging, the workpiece material is heated (often to extremely high temperatures) while remaining solid. In die casting, the

Casting and forging are two common manufacturing processes in metalworking that differ significantly in their principles, applications and characteristics. Casting and forging represent two fundamental approaches to shaping metal, each

Die Casting vs Forging: Die casting uses high-pressure injection for precision, while forging applies compressive force for strength. Die casting and forging are two widely used manufacturing processes for producing

During the die-casting process, the high-temperature and high-pressure operation of molten aluminum poses certain risks: During the die-casting process, the high-temperature and high-pressure operation of molten aluminum poses certain risks,

Safety operation rules of die casting machine requires maintaining constant vigilance through the use of appropriate personal protective equipment, daily inspections, and strict adherence to procedures under both normal and

Die casting machine safety systems are a combination of multiple protection: physical barriers (guard doors), detection devices (travel switches, lasers), control system interlocks, emergency braking (safety valves, emergency stop switches)

Safety practices during metal casting is crucial to prevent injuries and ensure a safe working environment. Metal casting involves several hazards, including high temperatures, molten metal, fumes, and heavy equipment.The die-casting process